|

|

@@ -1,20 +1,21 @@

|

|

1

|

|

-title: i3 AM8

|

|

|

1

|

+title: i3 CoreXZ AM8

|

|

2

|

2

|

description: Rebuild of my i3 clone with aluminium extrusions, CoreXZ, Klipper

|

|

3

|

|

-x-parent: 3d-printing

|

|

4

|

|

-x-position: 25

|

|

5

|

|

-x-date: 2022-02-01

|

|

6

|

|

-x-update: 2022-06-10

|

|

7

|

|

-x-comments: true

|

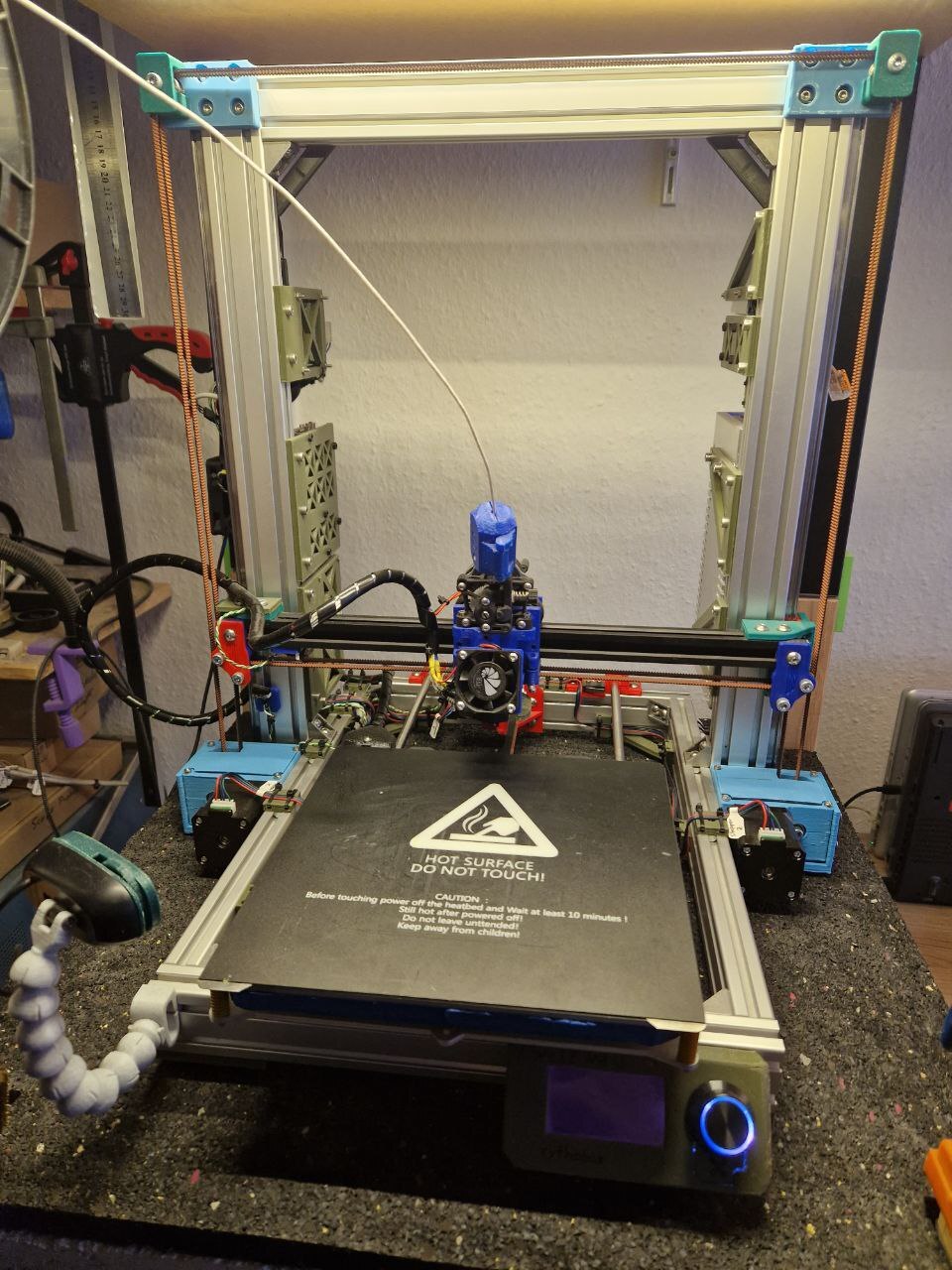

|

|

3

|

+parent: 3d-printing

|

|

|

4

|

+position: 10

|

|

|

5

|

+date: 2022-10-08

|

|

|

6

|

+comments: true

|

|

8

|

7

|

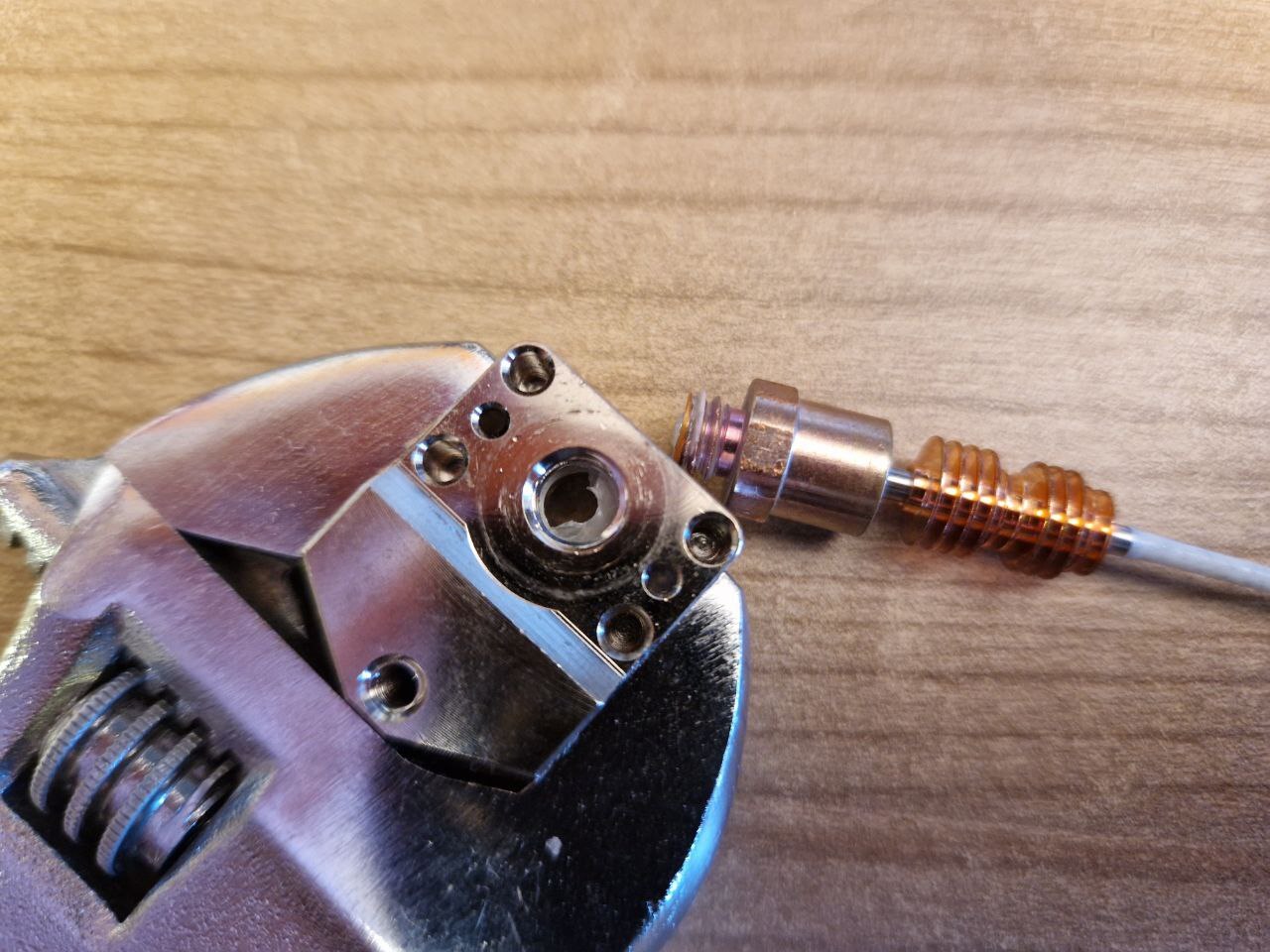

---

|

|

9

|

8

|

|

|

10

|

9

|

<!--% backToParent() %-->

|

|

11

|

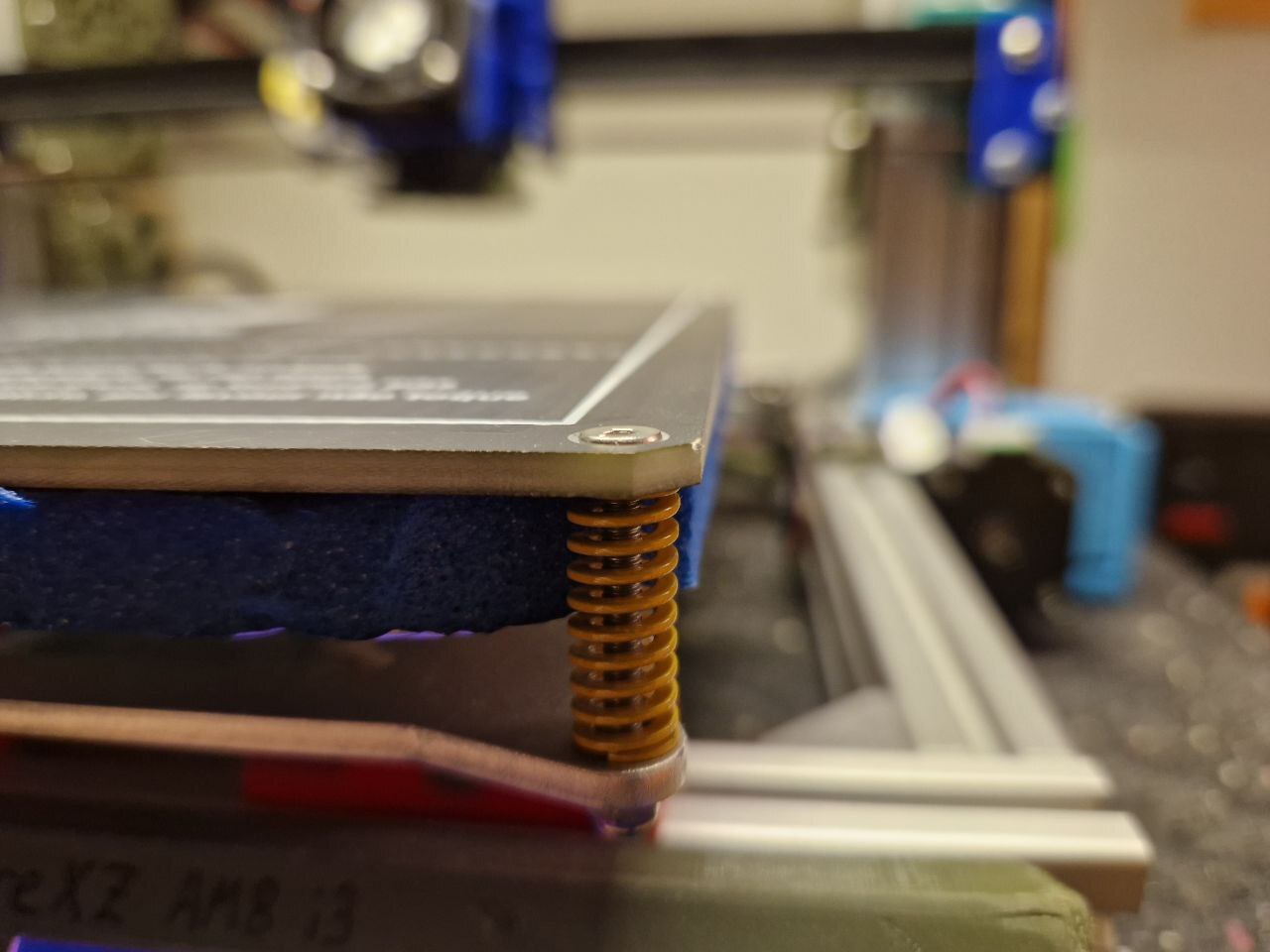

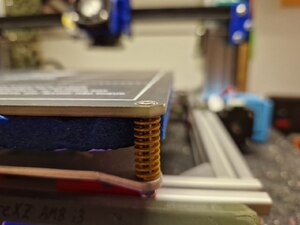

10

|

|

|

12

|

11

|

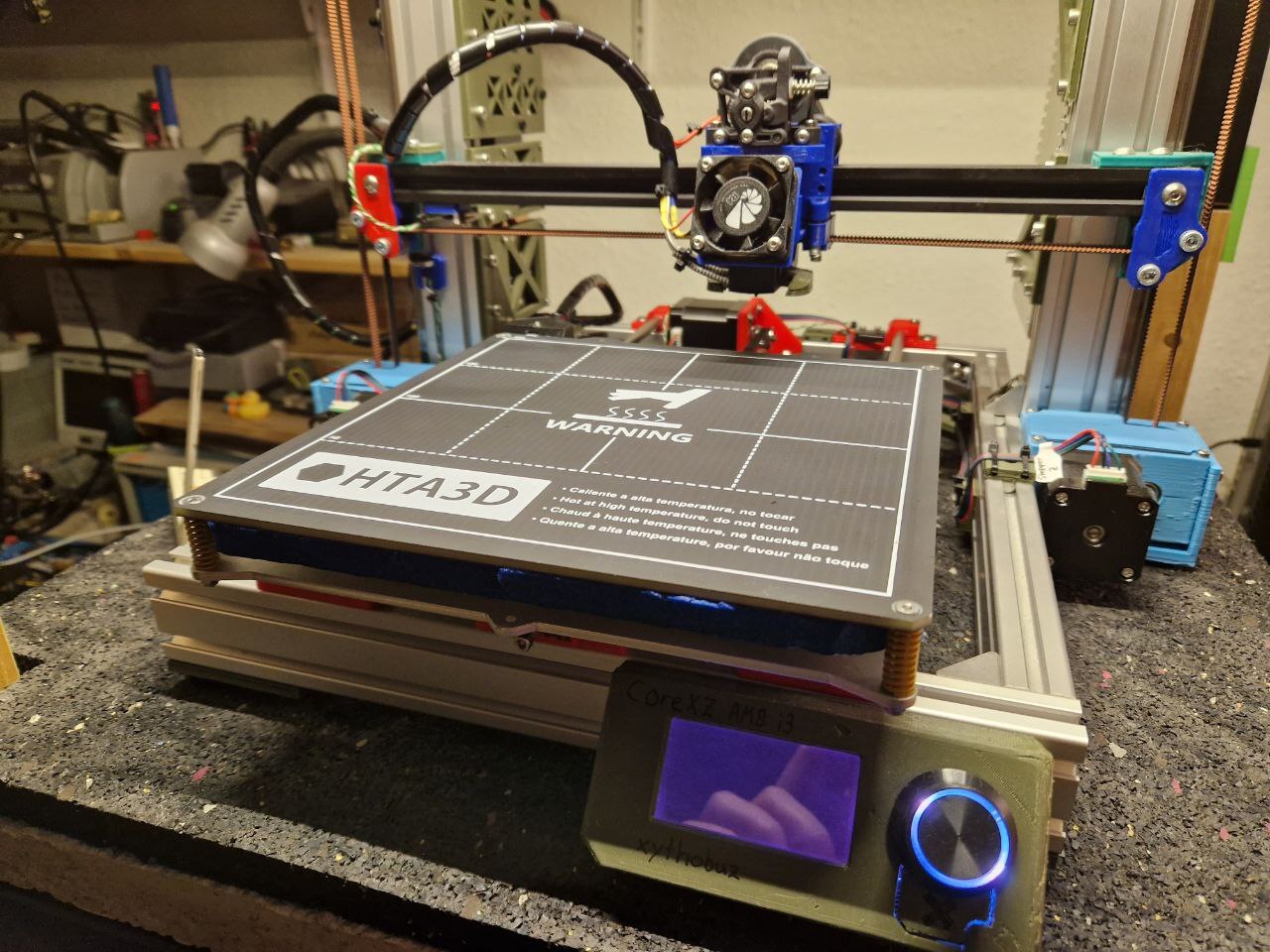

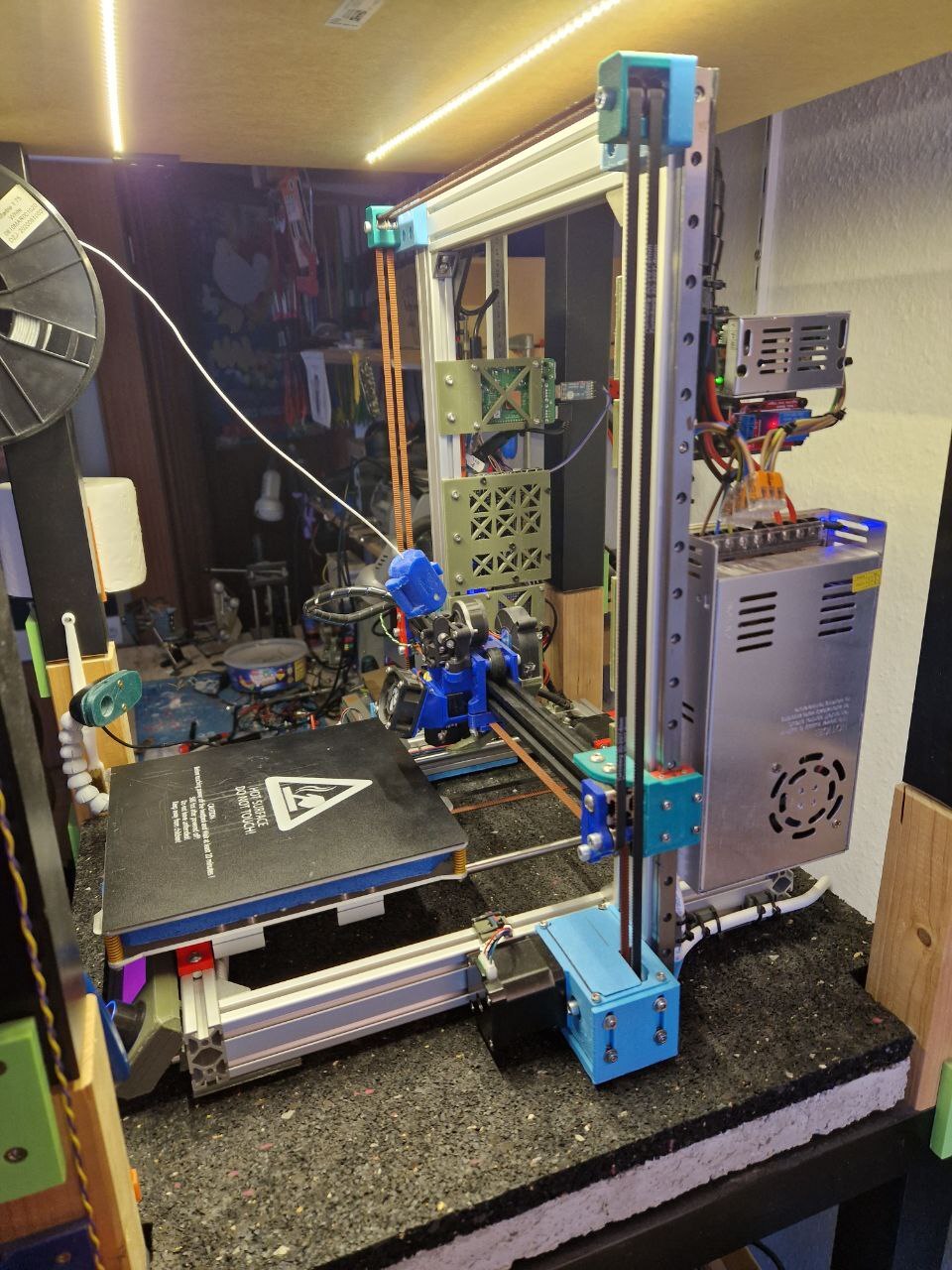

In February 2022 I finally decided to re-build my [CTC i3 Pro B](ctc-i3.html) with an upgraded frame and better parts.

|

|

|

12

|

+It took me quite some time, until September of 2022, to finally get it running properly.

|

|

13

|

13

|

|

|

14

|

14

|

<!--%

|

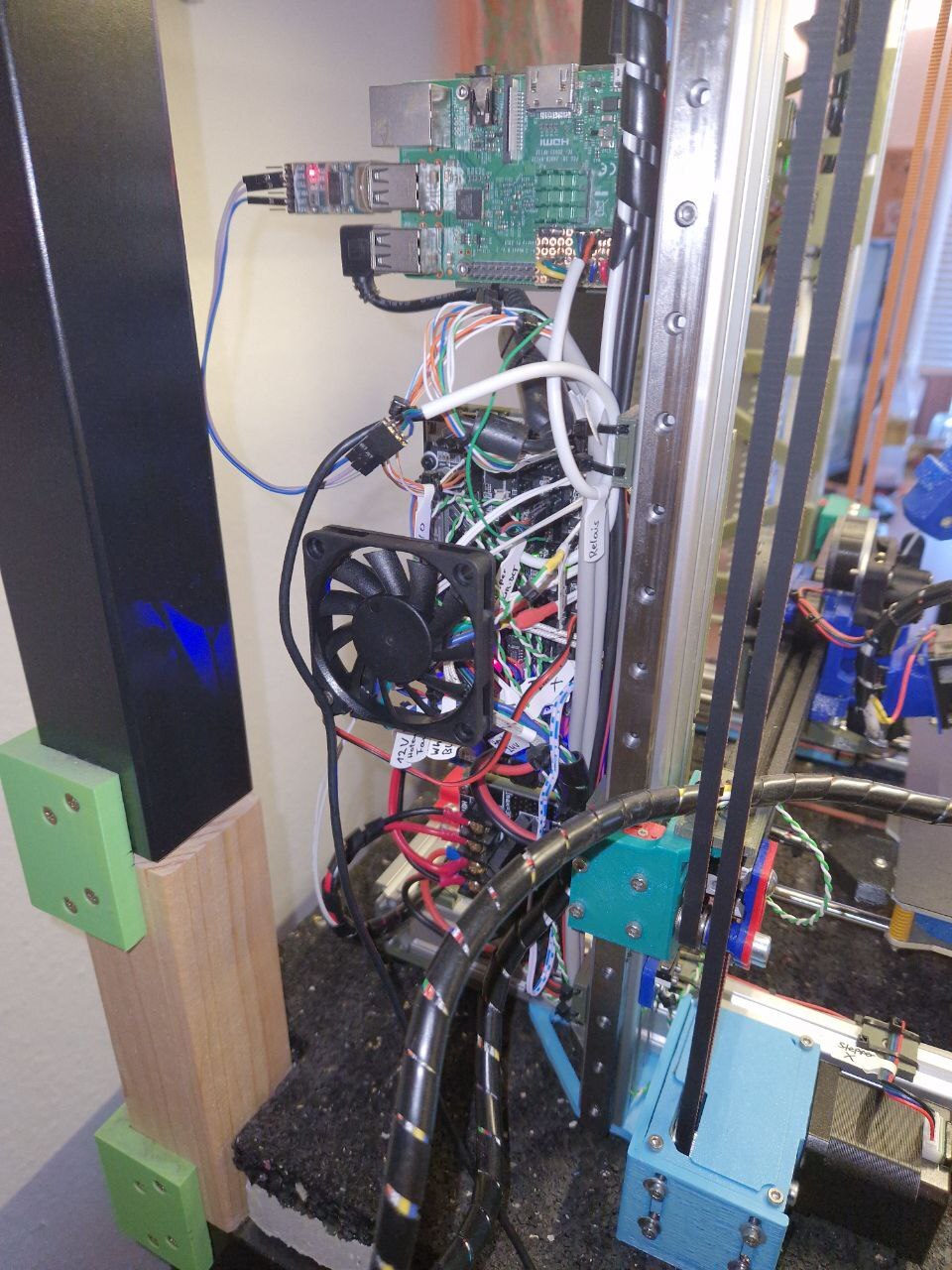

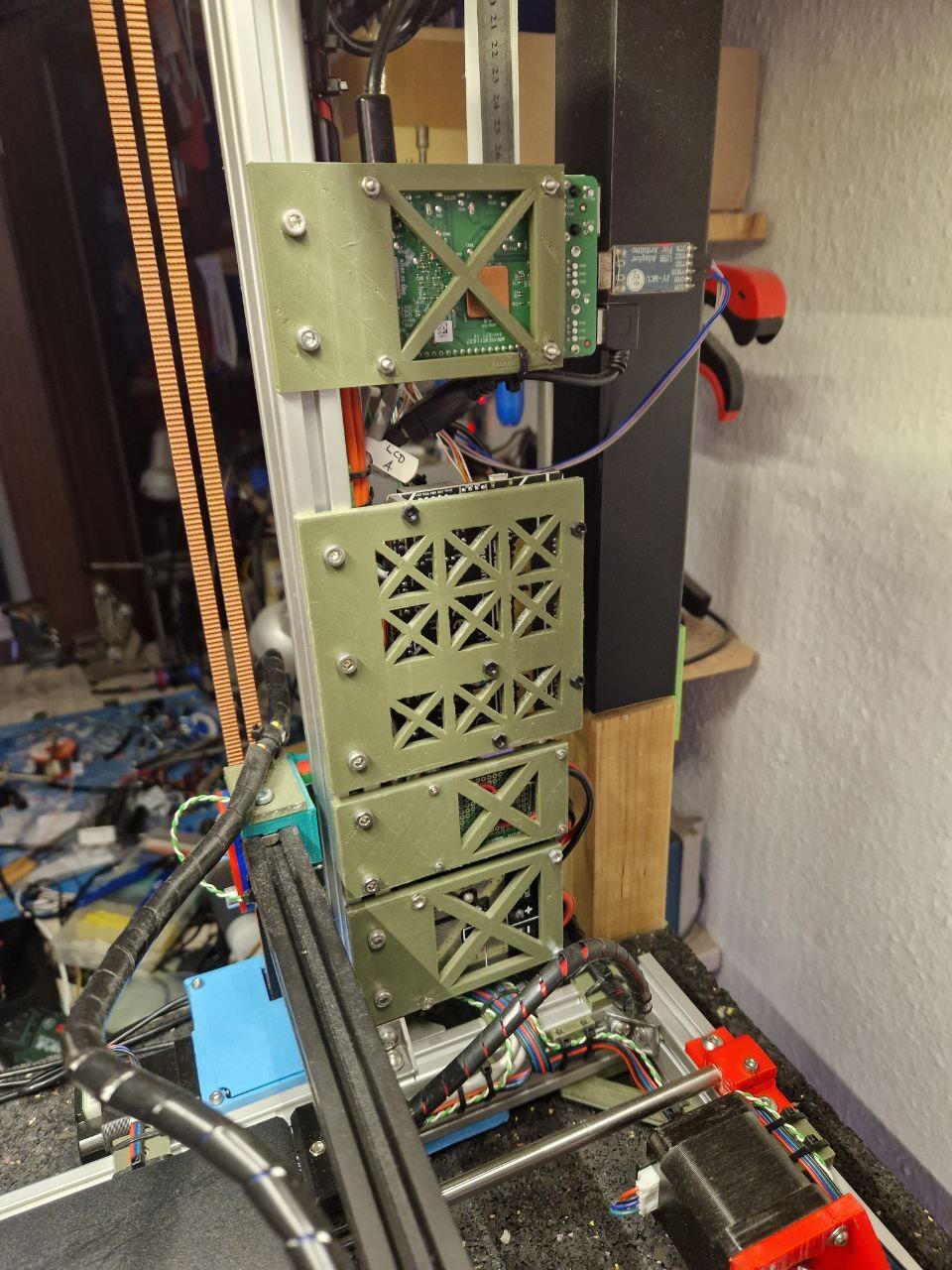

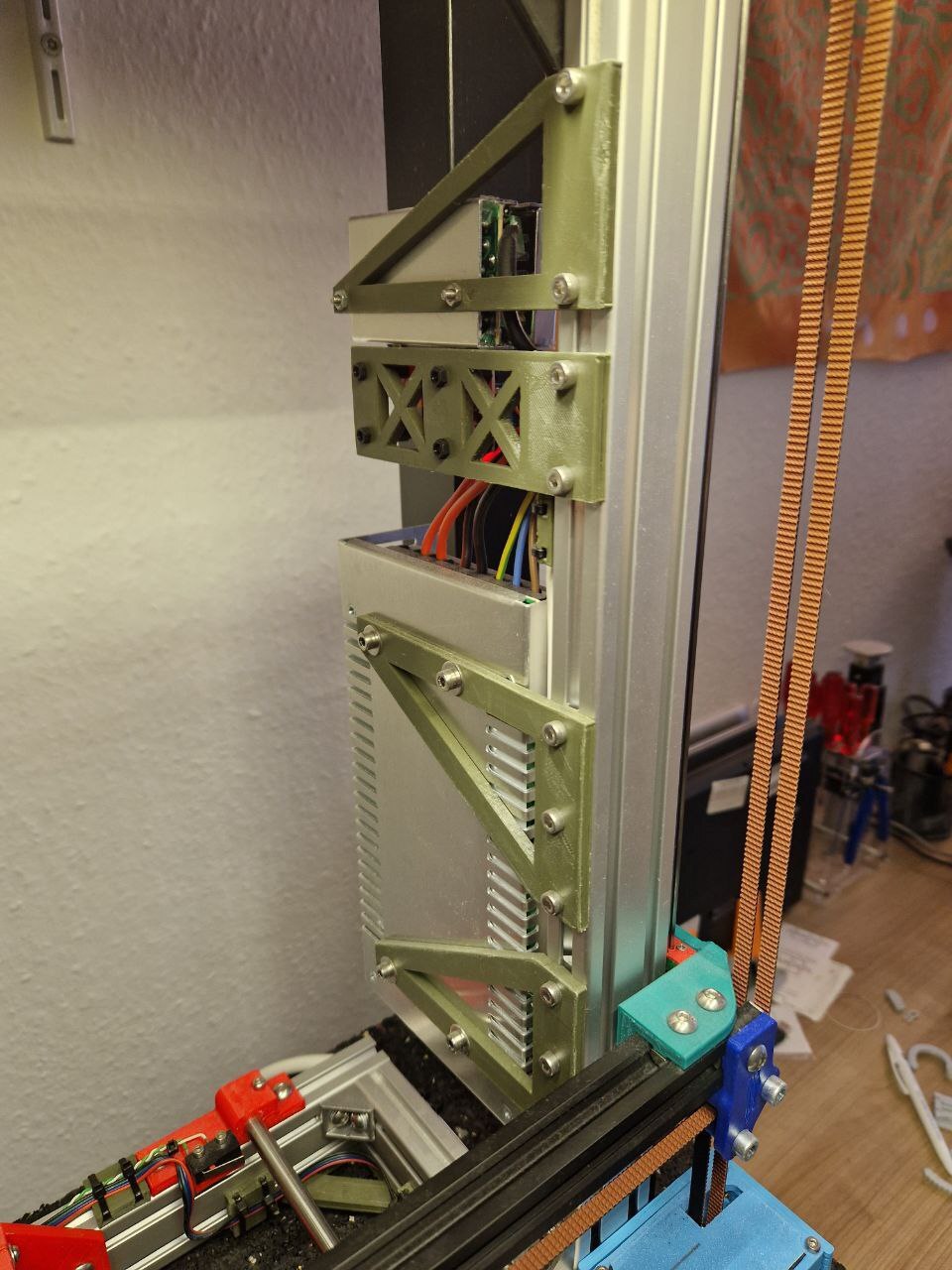

|

15

|

15

|

lightgallery([

|

|

16

|

|

- [ "img/am8_front_top.jpg", "Front top view, without bed"],

|

|

17

|

|

- [ "img/am8_front_bottom.jpg", "Front bottom view, without bed"],

|

|

|

16

|

+ [ "img/am8_front.jpg", "Front view of completed printer"],

|

|

|

17

|

+ [ "img/am8_left.jpg", "View of PCBs on left side"],

|

|

|

18

|

+ [ "img/am8_right.jpg", "View of power supplies on right side"],

|

|

18

|

19

|

])

|

|

19

|

20

|

%-->

|

|

20

|

21

|

|

|

|

@@ -31,26 +32,110 @@ The following are the new integral components:

|

|

31

|

32

|

* [SKR Mini E3 v3.0 Mainboard](https://github.com/bigtreetech/BIGTREETECH-SKR-mini-E3/tree/master/hardware/BTT%20SKR%20MINI%20E3%20V3.0)

|

|

32

|

33

|

* [Fysetc Mini 128x64 LCD panel V2.1](https://wiki.fysetc.com/Mini12864_Panel/)

|

|

33

|

34

|

* Cloned version by [BCZAMD on Amazon](https://amzn.to/3MaaJ6T)

|

|

|

35

|

+ * [Magnetic Heatbed (Mk52 clone)](https://www.hta3d.com/en/magnetic-heated-bed-220x200mm-with-inserted-magnets-24v-similar-mk52-mk3)

|

|

34

|

36

|

|

|

35

|

37

|

Initially I simply wanted to re-use the mechanical parts from my old printer.

|

|

36

|

38

|

But after talking to my friend [Tobias](https://www.prusaprinters.org/social/199673-93djen/about) about the project, he came up with the idea to convert the AM8 into a CoreXZ machine, and also immediately delivered a complete design!

|

|

37

|

39

|

We selected the parts based on what I mostly still had lying around.

|

|

38

|

40

|

|

|

|

41

|

+Other mechanical / electronical parts, like motors and the heatbed, I planned to re-use from my previous printer.

|

|

|

42

|

+In the end that plan didn't quite work out and the only part that's still "original" is my heatbed MOSFET, everything else was replaced.

|

|

|

43

|

+

|

|

|

44

|

+## Frame / CoreXZ

|

|

|

45

|

+

|

|

|

46

|

+<!--%

|

|

|

47

|

+lightgallery([

|

|

|

48

|

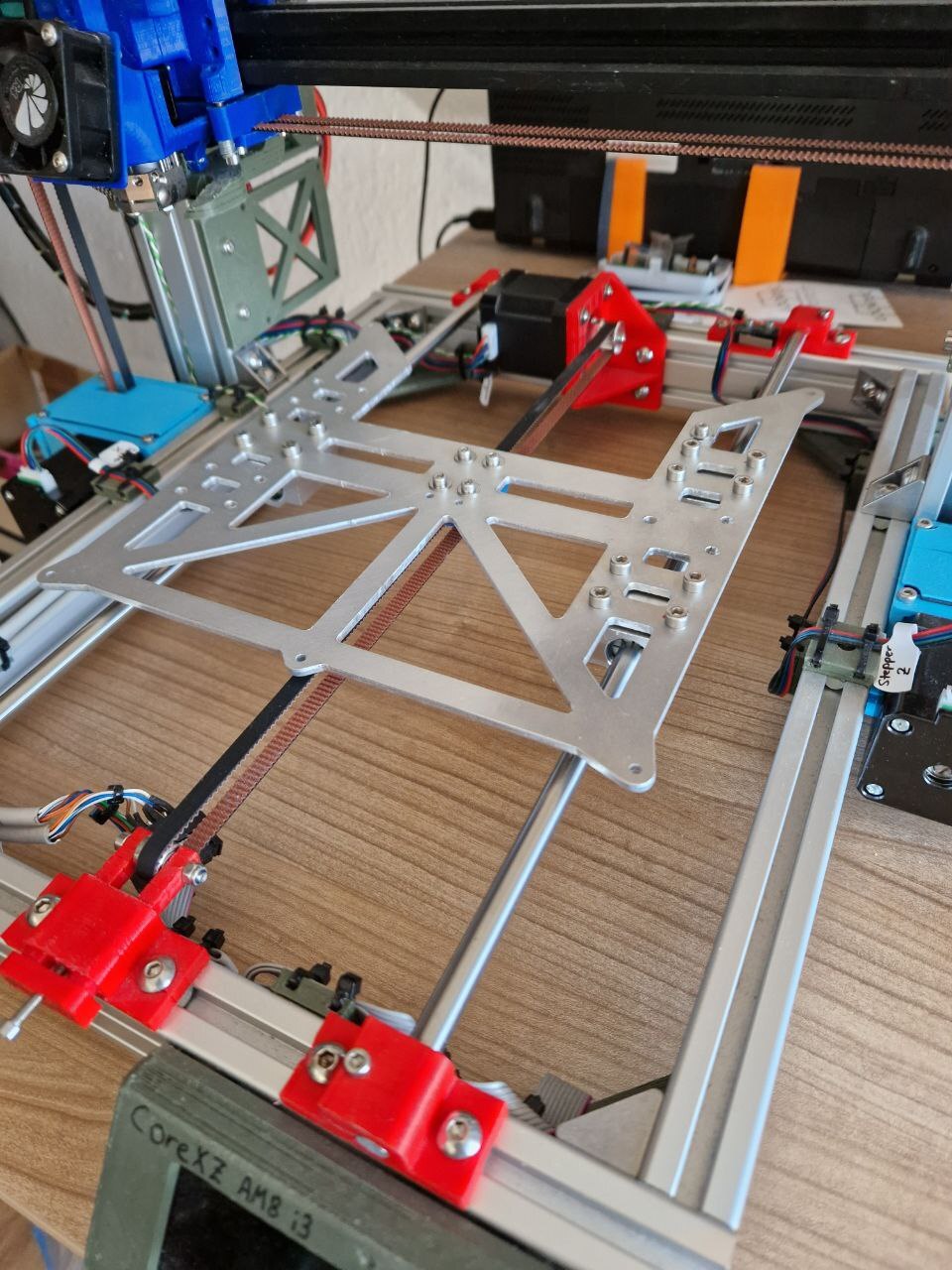

+ [ "img/am8_front_top.jpg", "Front top view, without bed"],

|

|

|

49

|

+ [ "img/am8_front_bottom.jpg", "Front bottom view, without bed"],

|

|

|

50

|

+])

|

|

|

51

|

+%-->

|

|

|

52

|

+

|

|

|

53

|

+This is my first time going from simple i3-style mechanics to something more complicated, like CoreXY or CoreXZ.

|

|

|

54

|

+It has some advantages and drawbacks.

|

|

|

55

|

+I really like that leveling the Z-axis, or losing steps on only one of the two Z steppers, is a thing of the past.

|

|

|

56

|

+Instead, now the rotation of the X-axis is determined by the relative tension of the two long belts.

|

|

|

57

|

+Tensioning one of the belts, the corresponding side of the X-axis rises or lowers.

|

|

|

58

|

+By using a simple [3D printed tool](https://www.printables.com/model/115460-belt-tension-gauge-source-file-included) the tension can be measured and dialed in relatively well.

|

|

|

59

|

+For fine tuning, you can induce an oscillation on the belt with your finger and compare the pitch of the resulting noise.

|

|

|

60

|

+

|

|

39

|

61

|

<!--%

|

|

40

|

62

|

lightgallery([

|

|

41

|

63

|

[ "img/am8_corexz_1.png", "CAD screenshot of whole CoreXZ AM8"],

|

|

42

|

|

- [ "img/am8_corexz_2.png", "CAD screenshot of extruder / hotend"],

|

|

43

|

64

|

[ "img/am8_corexz_3.png", "CAD screenshot of XZ gearbox"],

|

|

44

|

65

|

])

|

|

45

|

66

|

%-->

|

|

46

|

67

|

|

|

47

|

|

-Other mechanical / electronical parts, like motors and the heatbed, I re-used from my previous printer.

|

|

|

68

|

+At the beginning I had some problems getting the CoreXZ mechanism to work reliably.

|

|

|

69

|

+It took me far longer than I'd like to admit to find the root issue.

|

|

|

70

|

+The GT2 belt I ordered was not, in fact, a GT2 belt with 2mm pitch, but a T2.5 belt with 2.5mm pitch, and a slightly different tooth profile (square instead of rounded).

|

|

|

71

|

+This was close enough so you don't immediately notice a problem, but still caused some slip on the axes.

|

|

|

72

|

+This resulted in the axis dropping down in Z slightly with every move of the X axis.

|

|

|

73

|

+

|

|

|

74

|

+## Hotend

|

|

|

75

|

+

|

|

|

76

|

+<!--%

|

|

|

77

|

+lightgallery([

|

|

|

78

|

+ [ "img/am8_corexz_2.png", "CAD screenshot of extruder / hotend"],

|

|

|

79

|

+])

|

|

|

80

|

+%-->

|

|

|

81

|

+

|

|

|

82

|

+I'm using a [Sherpa Mini Extruder](https://github.com/Annex-Engineering/Sherpa_Mini-Extruder) together with an NF Crazy High-Flow hotend, both ordered from Mellow on AliExpress.

|

|

|

83

|

+These are put on the x-carriage with only a 5015 fan for the filament, a 4020 fan for the hotend and a BL-Touch for auto-leveling.

|

|

|

84

|

+This makes for a very lightweight carriage that can reach high accelerations and speeds.

|

|

|

85

|

+And thanks to the v-rollers in the aluminium extrusion it moves very silently, as well.

|

|

|

86

|

+

|

|

|

87

|

+<!--%

|

|

|

88

|

+lightgallery([

|

|

|

89

|

+ [ "img/am8_hotend.jpg", ""],

|

|

|

90

|

+ [ "img/am8_heatbreak.jpg", ""],

|

|

|

91

|

+])

|

|

|

92

|

+%-->

|

|

|

93

|

+

|

|

|

94

|

+I had some problems initially with the NF Crazy clogging with low layer heights.

|

|

|

95

|

+This required some disassembly and cleaning of molten plastic.

|

|

|

96

|

+I'm not quite sure yet what is going on there and will investigate further.

|

|

|

97

|

+

|

|

|

98

|

+## Heatbed

|

|

|

99

|

+

|

|

|

100

|

+I initially hoped to re-use my old heatbed, but it turned out it is only compatible to 12V.

|

|

|

101

|

+So I had to order a 24V variant.

|

|

|

102

|

+I decided to go with this [Mk52 clone magnetic heatbed](https://www.hta3d.com/en/magnetic-heated-bed-220x200mm-with-inserted-magnets-24v-similar-mk52-mk3) from HTA3D.

|

|

|

103

|

+The magnets in there are apparently good up to 140 degrees C.

|

|

|

104

|

+I was able to re-use the coated spring-steel-sheet printing surface from my old printer.

|

|

|

105

|

+It already came with a nice printed housing for the cable connections, and a Thermistor pre-installed.

|

|

|

106

|

+I asked the vendor, it is an `EPCOS 100K B57560G104F` in Klipper, or option 1 in Marlin.

|

|

|

107

|

+

|

|

|

108

|

+<!--%

|

|

|

109

|

+lightgallery([

|

|

|

110

|

+ [ "img/am8_bed_bottom.jpg", ""],

|

|

|

111

|

+ [ "img/am8_bed_conn.jpg", ""],

|

|

|

112

|

+ [ "img/am8_bed_insulation.jpg", ""],

|

|

|

113

|

+])

|

|

|

114

|

+%-->

|

|

|

115

|

+

|

|

|

116

|

+Of course I put a piece of [insulation foam](https://www.hta3d.com/en/adhesive-thermal-insulation-for-heatedbed) on the bottom of the bed.

|

|

|

117

|

+I installed it using some [flat 20mm springs](https://amzn.to/3ChnetC) on my [Y carriage](https://amzn.to/3CHQR8T).

|

|

|

118

|

+

|

|

|

119

|

+<!--%

|

|

|

120

|

+lightgallery([

|

|

|

121

|

+ [ "img/am8_y_carriage.jpg", ""],

|

|

|

122

|

+ [ "img/am8_bed_pcb.jpg", ""],

|

|

|

123

|

+ [ "img/am8_bed_spring.jpg", ""],

|

|

|

124

|

+])

|

|

|

125

|

+%-->

|

|

48

|

126

|

|

|

49

|

127

|

## Custom 3D-Printed Parts

|

|

50

|

128

|

|

|

51

|

|

-Mounts for PSUs, MOSFET, Mainboard, Pi, Relais.

|

|

|

129

|

+To install all the modules and PCBs to the frame I decided to design some simple mounting plates for myself.

|

|

|

130

|

+

|

|

|

131

|

+<!--%

|

|

|

132

|

+lightgallery([

|

|

|

133

|

+ [ "img/am8_mounts_1.jpg", "View of PCB mounts"],

|

|

|

134

|

+ [ "img/am8_mounts_2.jpg", "View of PSU mounts"],

|

|

|

135

|

+])

|

|

|

136

|

+%-->

|

|

52

|

137

|

|

|

53

|

|

-TODO links, photos

|

|

|

138

|

+You can find these files [on my Printables profile](https://www.printables.com/model/291049-mounting-plates-for-am8) or [in my Git repo](https://git.xythobuz.de/thomas/3d-print-designs/src/branch/master/am8).

|

|

54

|

139

|

|

|

55

|

140

|

## Power Supply Wiring

|

|

56

|

141

|

|

|

|

@@ -123,9 +208,10 @@ lightgallery([

|

|

123

|

208

|

])

|

|

124

|

209

|

%-->

|

|

125

|

210

|

|

|

126

|

|

-TODO display no longer showing anything

|

|

127

|

|

-

|

|

128

|

|

-TODO problems with encoder, kill button pullups?!

|

|

|

211

|

+This was the first time I tried to solder to ethernet cable.

|

|

|

212

|

+It seems to have some kind of coating that makes it not only hard to wet with tin,

|

|

|

213

|

+it also corroded one of my soldering tips pretty strongly.

|

|

|

214

|

+Not all connections were good, and I had some issues with the LCD not displaying anything after a short time.

|

|

129

|

215

|

|

|

130

|

216

|

<!--%

|

|

131

|

217

|

lightgallery([

|

|

|

@@ -153,9 +239,6 @@ And I have to admit, even though I didn't believe it at first, it's much better

|

|

153

|

239

|

I'm using [MainsailOS](https://docs.mainsail.xyz/setup/mainsail-os) on a Raspberry Pi 3B.

|

|

154

|

240

|

Installation and Configuration was really straight-forward with the configuration guides of [Klipper](https://www.klipper3d.org/Config_Reference.html) and [Mainsail](https://docs.mainsail.xyz/setup/mainsailos/first-boot).

|

|

155

|

241

|

|

|

156

|

|

-Here is my current printer config file.

|

|

157

|

|

-<button type="button" onclick="copyEvent('printercfg')" class="clip-btn">Copy to clipboard</button>

|

|

158

|

|

-

|

|

159

|

242

|

<!-- https://clay-atlas.com/us/blog/2021/06/30/html-en-copy-text-button/ -->

|

|

160

|

243

|

<script>

|

|

161

|

244

|

function copyEvent(id) {

|

|

|

@@ -165,6 +248,9 @@ function copyEvent(id) {

|

|

165

|

248

|

}

|

|

166

|

249

|

</script>

|

|

167

|

250

|

|

|

|

251

|

+Here is my current `printer.cfg` file.

|

|

|

252

|

+<button type="button" onclick="copyEvent('printercfg')" class="clip-btn">Copy 'printer.cfg' to clipboard</button>

|

|

|

253

|

+

|

|

168

|

254

|

<pre id="printercfg" class="sh_desktop">

|

|

169

|

255

|

[include mainsail.cfg]

|

|

170

|

256

|

|

|

|

@@ -176,6 +262,7 @@ function copyEvent(id) {

|

|

176

|

262

|

kinematics: corexz

|

|

177

|

263

|

max_velocity: 200

|

|

178

|

264

|

max_accel: 2000

|

|

|

265

|

+max_accel_to_decel: 2000

|

|

179

|

266

|

max_z_velocity: 200

|

|

180

|

267

|

max_z_accel: 500

|

|

181

|

268

|

|

|

|

@@ -196,6 +283,18 @@ aliases:

|

|

196

|

283

|

serial: /dev/serial/by-id/usb-FTDI_FT232R_USB_UART_A100OZQ1-if00-port0

|

|

197

|

284

|

restart_method: command

|

|

198

|

285

|

|

|

|

286

|

+[temperature_sensor microcontroller]

|

|

|

287

|

+sensor_type: temperature_mcu

|

|

|

288

|

+min_temp: 0

|

|

|

289

|

+max_temp: 90

|

|

|

290

|

+gcode_id: mcu

|

|

|

291

|

+

|

|

|

292

|

+[temperature_sensor raspberry_pi]

|

|

|

293

|

+sensor_type: temperature_host

|

|

|

294

|

+min_temp: 0

|

|

|

295

|

+max_temp: 90

|

|

|

296

|

+gcode_id: pi

|

|

|

297

|

+

|

|

199

|

298

|

##########################################

|

|

200

|

299

|

################# Motors #################

|

|

201

|

300

|

##########################################

|

|

|

@@ -204,22 +303,24 @@ restart_method: command

|

|

204

|

303

|

# stepper controlling the X+Z movement.

|

|

205

|

304

|

[stepper_x]

|

|

206

|

305

|

step_pin: PB13

|

|

207

|

|

-dir_pin: PB12

|

|

|

306

|

+dir_pin: !PB12

|

|

208

|

307

|

enable_pin: !PB14

|

|

209

|

308

|

microsteps: 16 # set by driver

|

|

210

|

309

|

full_steps_per_rotation: 200 # motor specific

|

|

211

|

310

|

gear_ratio: 36:20 # CoreXZ gearbox

|

|

212

|

311

|

rotation_distance: 40 # 20 teeth * 2mm belt

|

|

213

|

312

|

endstop_pin: ^!PC0

|

|

214

|

|

-position_endstop: 0.0

|

|

215

|

|

-position_max: 235

|

|

216

|

|

-homing_speed: 30

|

|

|

313

|

+position_endstop: -7.0

|

|

|

314

|

+position_min: -7.0

|

|

|

315

|

+position_max: 228.0

|

|

|

316

|

+homing_speed: 40

|

|

|

317

|

+second_homing_speed: 10

|

|

217

|

318

|

|

|

218

|

319

|

# The stepper_y section is used to describe the stepper controlling

|

|

219

|

320

|

# the Y axis.

|

|

220

|

321

|

[stepper_y]

|

|

221

|

322

|

step_pin: PB10

|

|

222

|

|

-dir_pin: !PB2

|

|

|

323

|

+dir_pin: PB2

|

|

223

|

324

|

enable_pin: !PB11

|

|

224

|

325

|

microsteps: 16 # set by driver

|

|

225

|

326

|

full_steps_per_rotation: 200 # motor specific

|

|

|

@@ -227,8 +328,10 @@ gear_ratio: 1:1 # driven directly

|

|

227

|

328

|

rotation_distance: 40 # 20 teeth * 2mm belt

|

|

228

|

329

|

endstop_pin: ^!PC1

|

|

229

|

330

|

position_endstop: 0.0

|

|

230

|

|

-position_max: 235

|

|

231

|

|

-homing_speed: 30

|

|

|

331

|

+position_min: 0.0

|

|

|

332

|

+position_max: 210.0

|

|

|

333

|

+homing_speed: 40

|

|

|

334

|

+second_homing_speed: 10

|

|

232

|

335

|

|

|

233

|

336

|

# The stepper_z section is used to describe the Z axis as well as the

|

|

234

|

337

|

# stepper controlling the X-Z movement.

|

|

|

@@ -242,8 +345,10 @@ gear_ratio: 36:20 # CoreXZ gearbox

|

|

242

|

345

|

rotation_distance: 40 # 20 teeth * 2mm belt

|

|

243

|

346

|

endstop_pin: ^!PC2

|

|

244

|

347

|

position_endstop: 0.0

|

|

245

|

|

-position_max: 250

|

|

246

|

|

-homing_speed: 20

|

|

|

348

|

+position_min: 0.0

|

|

|

349

|

+position_max: 275.0

|

|

|

350

|

+homing_speed: 40

|

|

|

351

|

+second_homing_speed: 10

|

|

247

|

352

|

|

|

248

|

353

|

[extruder]

|

|

249

|

354

|

step_pin: PB3

|

|

|

@@ -268,6 +373,17 @@ max_extrude_only_distance: 1400.0

|

|

268

|

373

|

max_extrude_only_velocity: 75.0

|

|

269

|

374

|

max_extrude_only_accel: 1500

|

|

270

|

375

|

|

|

|

376

|

+[heater_bed]

|

|

|

377

|

+heater_pin: PC9

|

|

|

378

|

+sensor_type: EPCOS 100K B57560G104F

|

|

|

379

|

+sensor_pin: PC4

|

|

|

380

|

+control: pid

|

|

|

381

|

+pid_Kp: 54.027

|

|

|

382

|

+pid_Ki: 0.770

|

|

|

383

|

+pid_Kd: 948.182

|

|

|

384

|

+min_temp: 0

|

|

|

385

|

+max_temp: 130

|

|

|

386

|

+

|

|

271

|

387

|

###########################################

|

|

272

|

388

|

################# TMC2209 #################

|

|

273

|

389

|

###########################################

|

|

|

@@ -276,21 +392,21 @@ max_extrude_only_accel: 1500

|

|

276

|

392

|

uart_pin: PC11

|

|

277

|

393

|

tx_pin: PC10

|

|

278

|

394

|

uart_address: 0

|

|

279

|

|

-#stealthchop_threshold: 999999

|

|

|

395

|

+stealthchop_threshold: 999999

|

|

280

|

396

|

run_current: 0.5

|

|

281

|

397

|

|

|

282

|

398

|

[tmc2209 stepper_y]

|

|

283

|

399

|

uart_pin: PC11

|

|

284

|

400

|

tx_pin: PC10

|

|

285

|

401

|

uart_address: 2

|

|

286

|

|

-#stealthchop_threshold: 999999

|

|

287

|

|

-run_current: 0.3

|

|

|

402

|

+stealthchop_threshold: 999999

|

|

|

403

|

+run_current: 0.6

|

|

288

|

404

|

|

|

289

|

405

|

[tmc2209 stepper_z]

|

|

290

|

406

|

uart_pin: PC11

|

|

291

|

407

|

tx_pin: PC10

|

|

292

|

408

|

uart_address: 1

|

|

293

|

|

-#stealthchop_threshold: 999999

|

|

|

409

|

+stealthchop_threshold: 999999

|

|

294

|

410

|

run_current: 0.5

|

|

295

|

411

|

|

|

296

|

412

|

[tmc2209 extruder]

|

|

|

@@ -298,20 +414,19 @@ uart_pin: PC11

|

|

298

|

414

|

tx_pin: PC10

|

|

299

|

415

|

uart_address: 3

|

|

300

|

416

|

stealthchop_threshold: 999999

|

|

301

|

|

-#interpolate: True

|

|

302

|

|

-run_current: 0.3

|

|

|

417

|

+run_current: 0.5

|

|

303

|

418

|

|

|

304

|

419

|

###########################################

|

|

305

|

420

|

############### Accessories ###############

|

|

306

|

421

|

###########################################

|

|

307

|

422

|

|

|

308

|

|

-[fan]

|

|

|

423

|

+[heater_fan nozzle_cooling_fan]

|

|

309

|

424

|

pin: PC6 # fan 0

|

|

310

|

425

|

|

|

311

|

|

-[heater_fan nozzle_cooling_fan]

|

|

|

426

|

+[fan]

|

|

312

|

427

|

pin: PC7 # fan 1

|

|

313

|

428

|

|

|

314

|

|

-[heater_fan controller_fan]

|

|

|

429

|

+[controller_fan controller_fan]

|

|

315

|

430

|

pin: PB15 # fan 2

|

|

316

|

431

|

|

|

317

|

432

|

###########################################

|

|

|

@@ -326,7 +441,7 @@ rst_pin: EXP1_5

|

|

326

|

441

|

contrast: 63

|

|

327

|

442

|

encoder_pins: ^IO_2, ^IO_3

|

|

328

|

443

|

click_pin: ^!EXP1_1

|

|

329

|

|

-kill_pin: ^IO_1

|

|

|

444

|

+#kill_pin: ^IO_1

|

|

330

|

445

|

spi_software_miso_pin: UNUSED

|

|

331

|

446

|

spi_software_mosi_pin: IO_5

|

|

332

|

447

|

spi_software_sclk_pin: IO_4

|

|

|

@@ -360,10 +475,84 @@ cycle_time: 0.001

|

|

360

|

475

|

[gcode_macro M300]

|

|

361

|

476

|

gcode:

|

|

362

|

477

|

# Use a default 1kHz tone if S is omitted.

|

|

363

|

|

- {% set S = params.S|default(1000)|int %}

|

|

|

478

|

+ \{% set S = params.S|default(1000)|int %}

|

|

364

|

479

|

# Use a 10ms duration is P is omitted.

|

|

365

|

|

- {% set P = params.P|default(100)|int %}

|

|

|

480

|

+ \{% set P = params.P|default(100)|int %}

|

|

366

|

481

|

SET_PIN PIN=beeper VALUE=0.5 CYCLE_TIME={ 1.0/S if S > 0 else 1 }

|

|

367

|

482

|

G4 P{P}

|

|

368

|

483

|

SET_PIN PIN=beeper VALUE=0

|

|

|

484

|

+

|

|

|

485

|

+##########################################

|

|

|

486

|

+############## Idle Timeout ##############

|

|

|

487

|

+##########################################

|

|

|

488

|

+

|

|

|

489

|

+# https://moonraker.readthedocs.io/en/latest/configuration/#toggling-device-state-from-klipper

|

|

|

490

|

+

|

|

|

491

|

+[gcode_macro POWER_OFF_PRINTER]

|

|

|

492

|

+gcode:

|

|

|

493

|

+ {action_call_remote_method("set_device_power",

|

|

|

494

|

+ device="printer",

|

|

|

495

|

+ state="off")}

|

|

|

496

|

+[delayed_gcode delayed_printer_off]

|

|

|

497

|

+initial_duration: 0.

|

|

|

498

|

+gcode:

|

|

|

499

|

+ \{% if printer.idle_timeout.state == "Idle" %}

|

|

|

500

|

+ POWER_OFF_PRINTER

|

|

|

501

|

+ \{% endif %}

|

|

|

502

|

+

|

|

|

503

|

+[idle_timeout]

|

|

|

504

|

+gcode:

|

|

|

505

|

+ M84

|

|

|

506

|

+ TURN_OFF_HEATERS

|

|

|

507

|

+ UPDATE_DELAYED_GCODE ID=delayed_printer_off DURATION=60

|

|

|

508

|

+</pre>

|

|

|

509

|

+

|

|

|

510

|

+Here is my current `moonraker.conf` file.

|

|

|

511

|

+<button type="button" onclick="copyEvent('moonrakerconf')" class="clip-btn">Copy 'moonraker.conf' to clipboard</button>

|

|

|

512

|

+

|

|

|

513

|

+<pre id="moonrakerconf" class="sh_desktop">

|

|

|

514

|

+[server]

|

|

|

515

|

+host: 0.0.0.0

|

|

|

516

|

+port: 7125

|

|

|

517

|

+# Verbose logging used for debugging . Default False.

|

|

|

518

|

+enable_debug_logging: False

|

|

|

519

|

+# The maximum size allowed for a file upload (in MiB). Default 1024 MiB

|

|

|

520

|

+max_upload_size: 1024

|

|

|

521

|

+

|

|

|

522

|

+[file_manager]

|

|

|

523

|

+config_path: ~/klipper_config

|

|

|

524

|

+log_path: ~/klipper_logs

|

|

|

525

|

+enable_object_processing: True

|

|

|

526

|

+queue_gcode_uploads: True

|

|

|

527

|

+

|

|

|

528

|

+# https://moonraker.readthedocs.io/en/latest/configuration/#power-on-g-code-uploads

|

|

|

529

|

+

|

|

|

530

|

+[job_queue]

|

|

|

531

|

+load_on_startup: True

|

|

|

532

|

+

|

|

|

533

|

+[power printer]

|

|

|

534

|

+type: gpio

|

|

|

535

|

+pin: gpiochip0/gpio4

|

|

|

536

|

+off_when_shutdown: True

|

|

|

537

|

+off_when_shutdown_delay: 2

|

|

|

538

|

+on_when_job_queued: True

|

|

|

539

|

+locked_while_printing: True

|

|

|

540

|

+restart_klipper_when_powered: True

|

|

|

541

|

+restart_delay: 1

|

|

|

542

|

+initial_state: off

|

|

|

543

|

+

|

|

|

544

|

+# enables partial support of Octoprint API

|

|

|

545

|

+[octoprint_compat]

|

|

|

546

|

+

|

|

|

547

|

+# enables moonraker to track and store print history.

|

|

|

548

|

+[history]

|

|

|

549

|

+

|

|

|

550

|

+# this enables moonraker's update manager

|

|

|

551

|

+[update_manager]

|

|

|

552

|

+refresh_interval: 168

|

|

|

553

|

+

|

|

|

554

|

+[update_manager mainsail]

|

|

|

555

|

+type: web

|

|

|

556

|

+repo: mainsail-crew/mainsail

|

|

|

557

|

+path: ~/mainsail

|

|

369

|

558

|

</pre>

|