|

|

@@ -0,0 +1,484 @@

|

|

|

1

|

+title: Trackball

|

|

|

2

|

+description: 3D printed mouse replacement with Raspberry Pi Pico and PMW3360

|

|

|

3

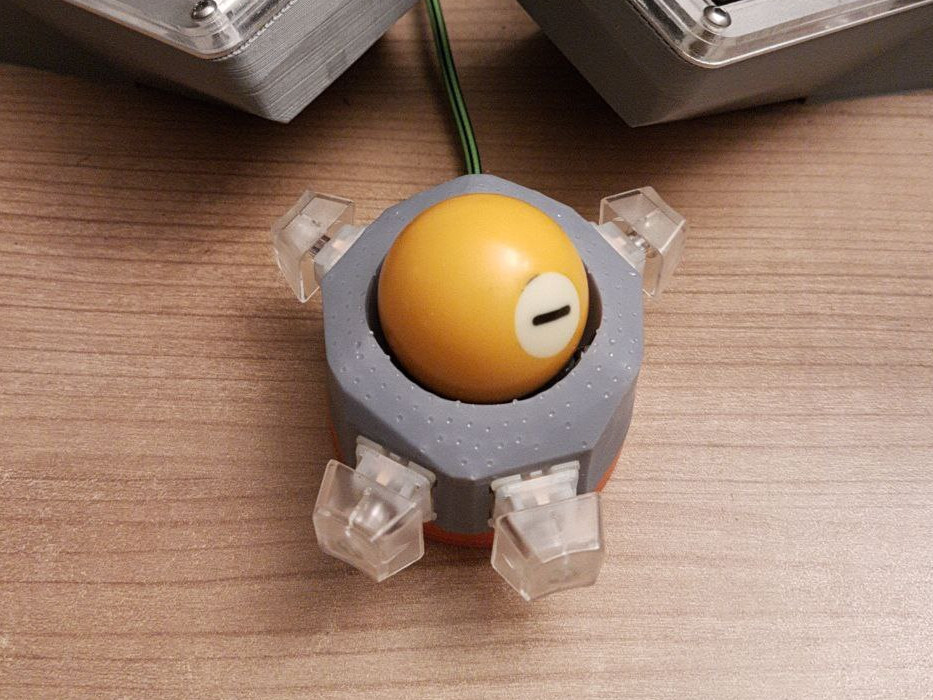

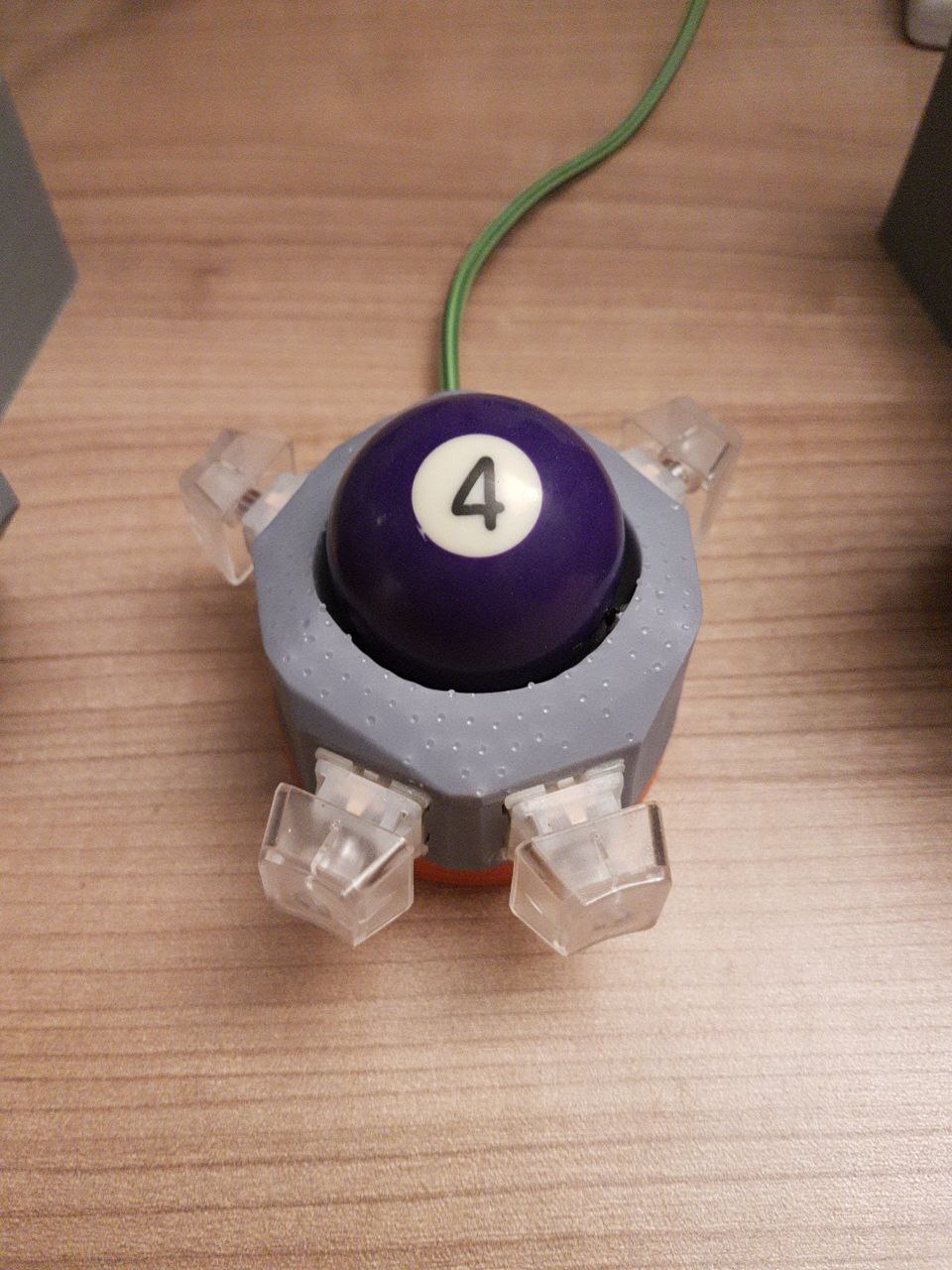

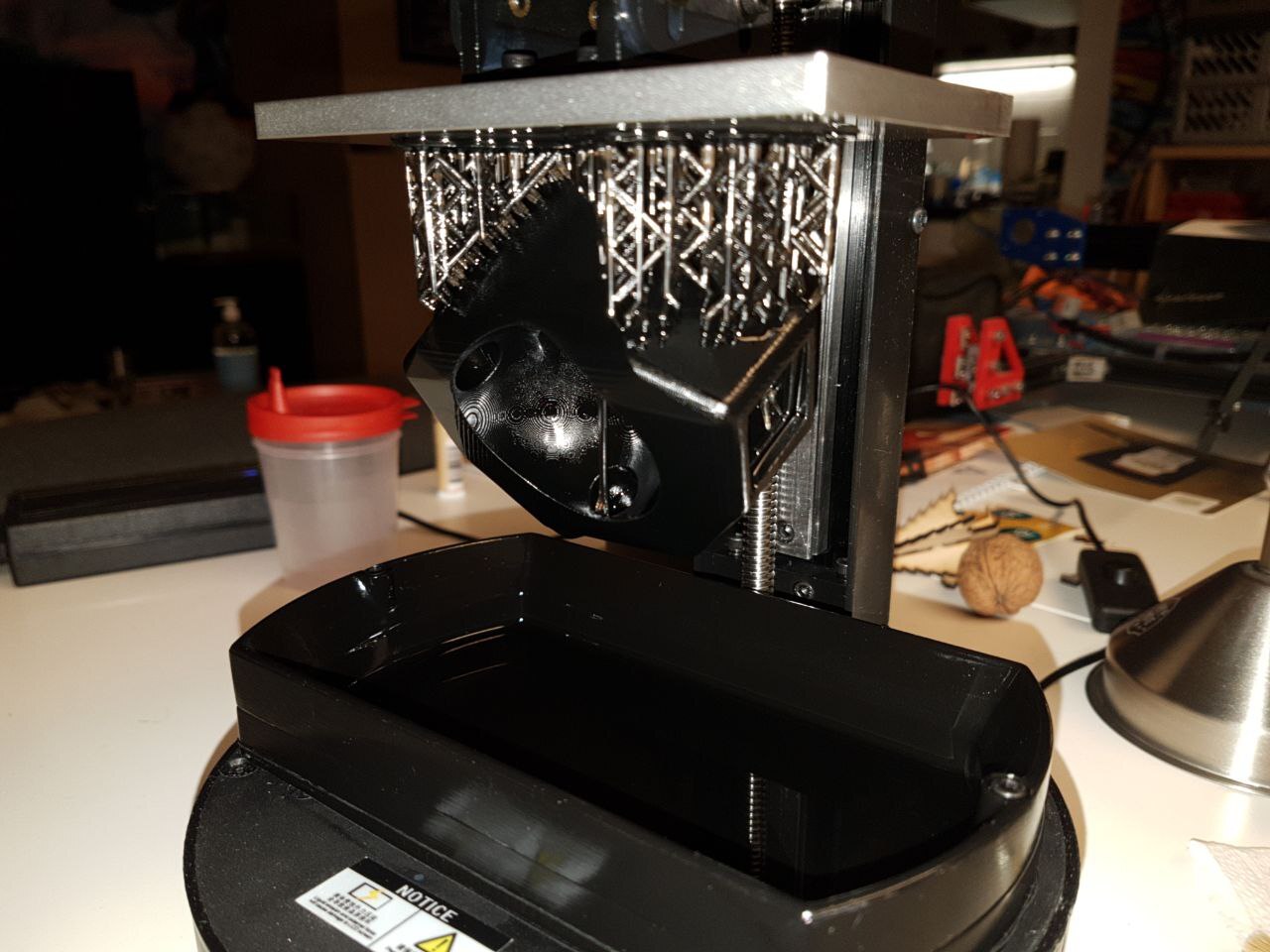

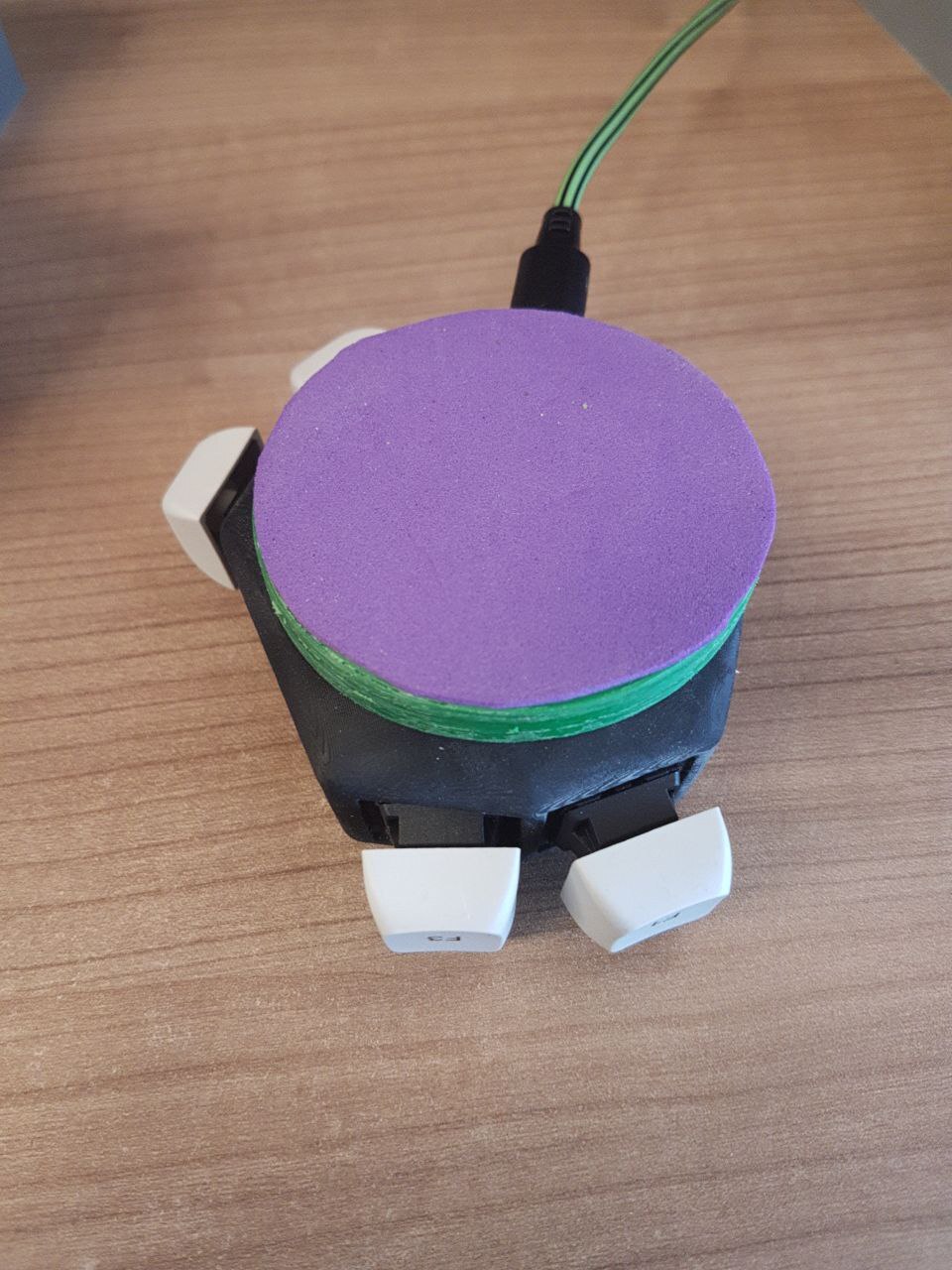

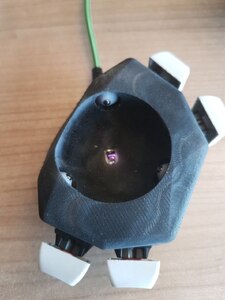

|

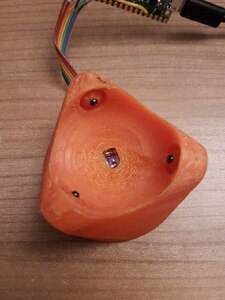

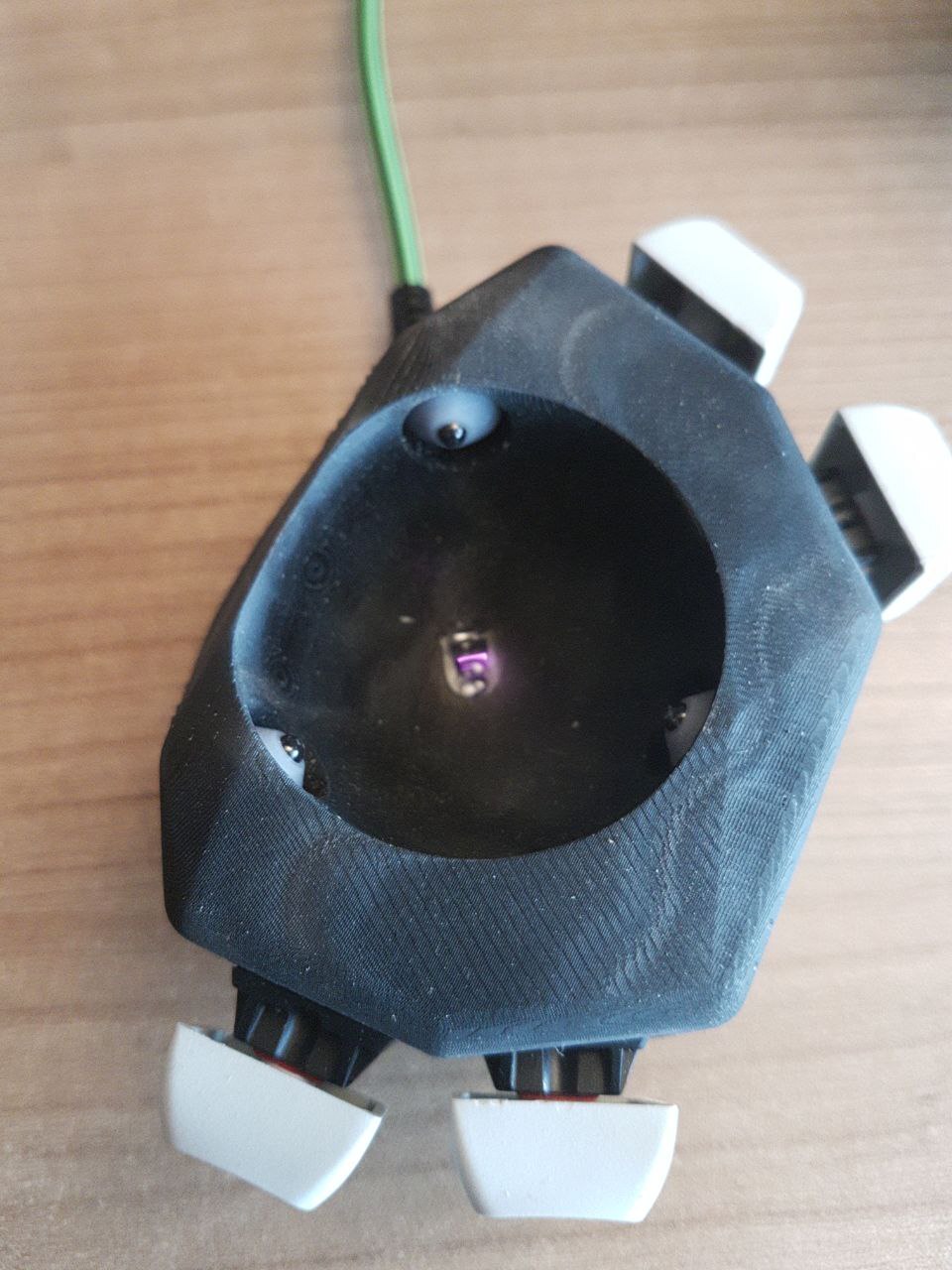

+parent: input_devices

|

|

|

4

|

+git: https://git.xythobuz.de/thomas/Trackball

|

|

|

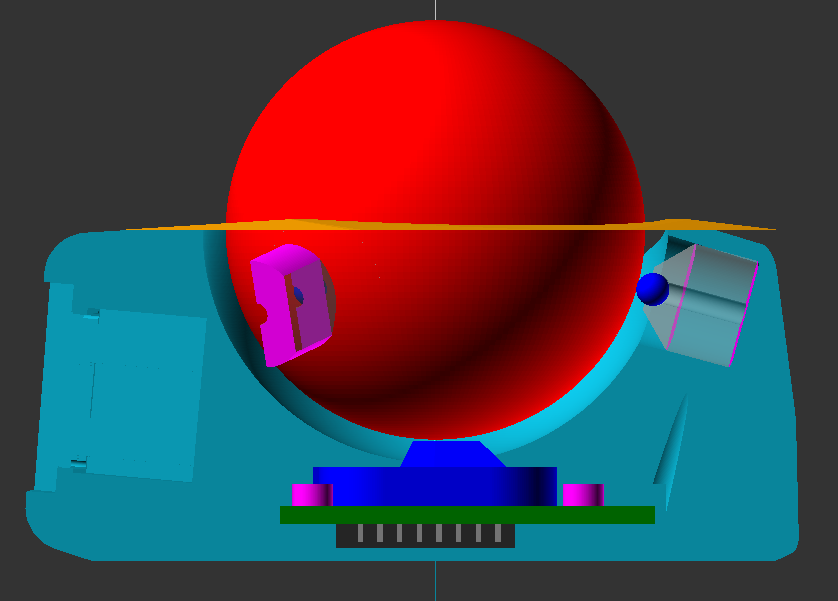

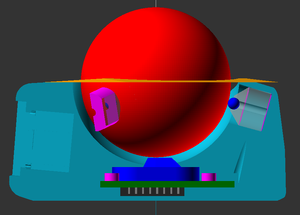

5

|

+github: https://github.com/xythobuz/Trackball

|

|

|

6

|

+date: 2023-02-12

|

|

|

7

|

+comments: true

|

|

|

8

|

+---

|

|

|

9

|

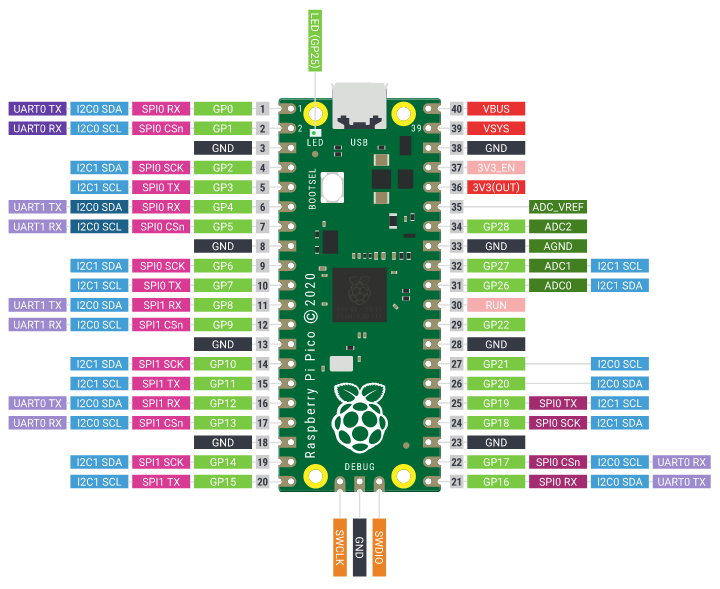

+

|

|

|

10

|

+<!--% backToParent() %-->

|

|

|

11

|

+

|

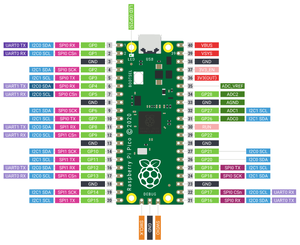

|

|

12

|

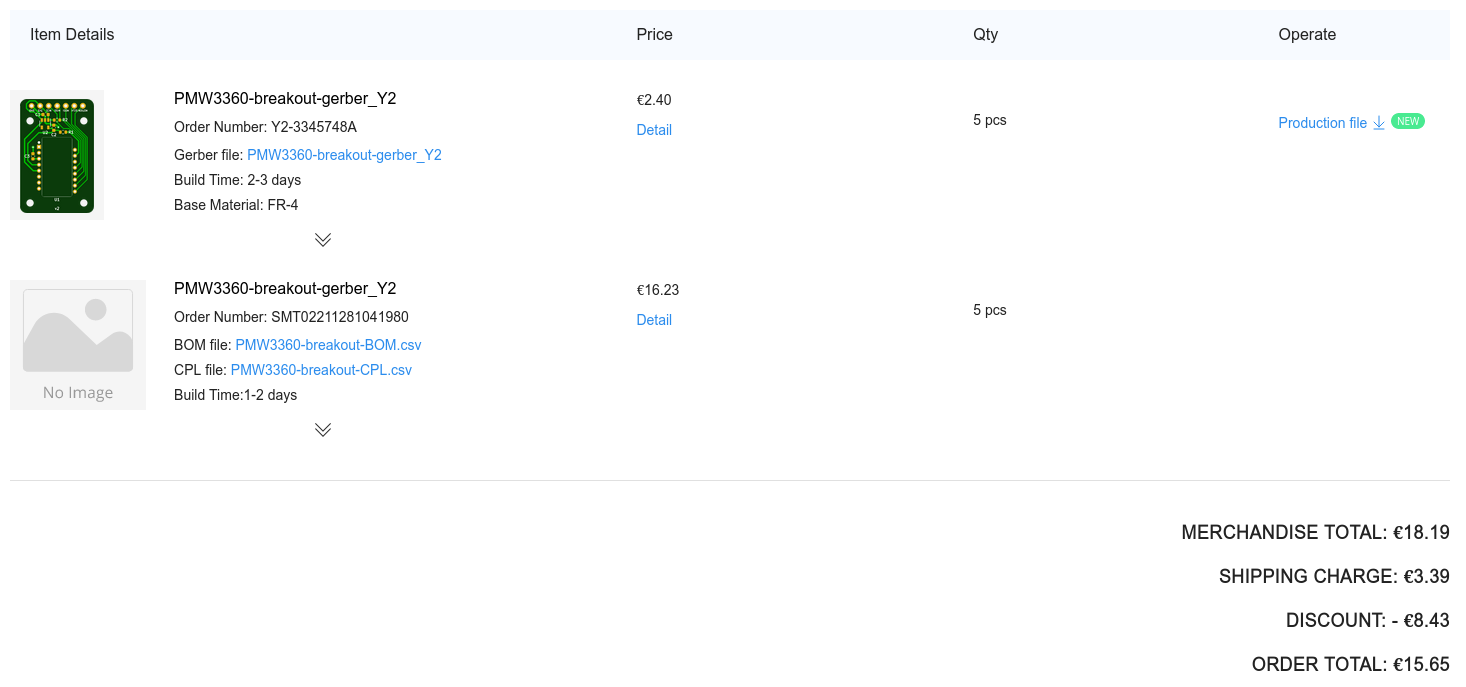

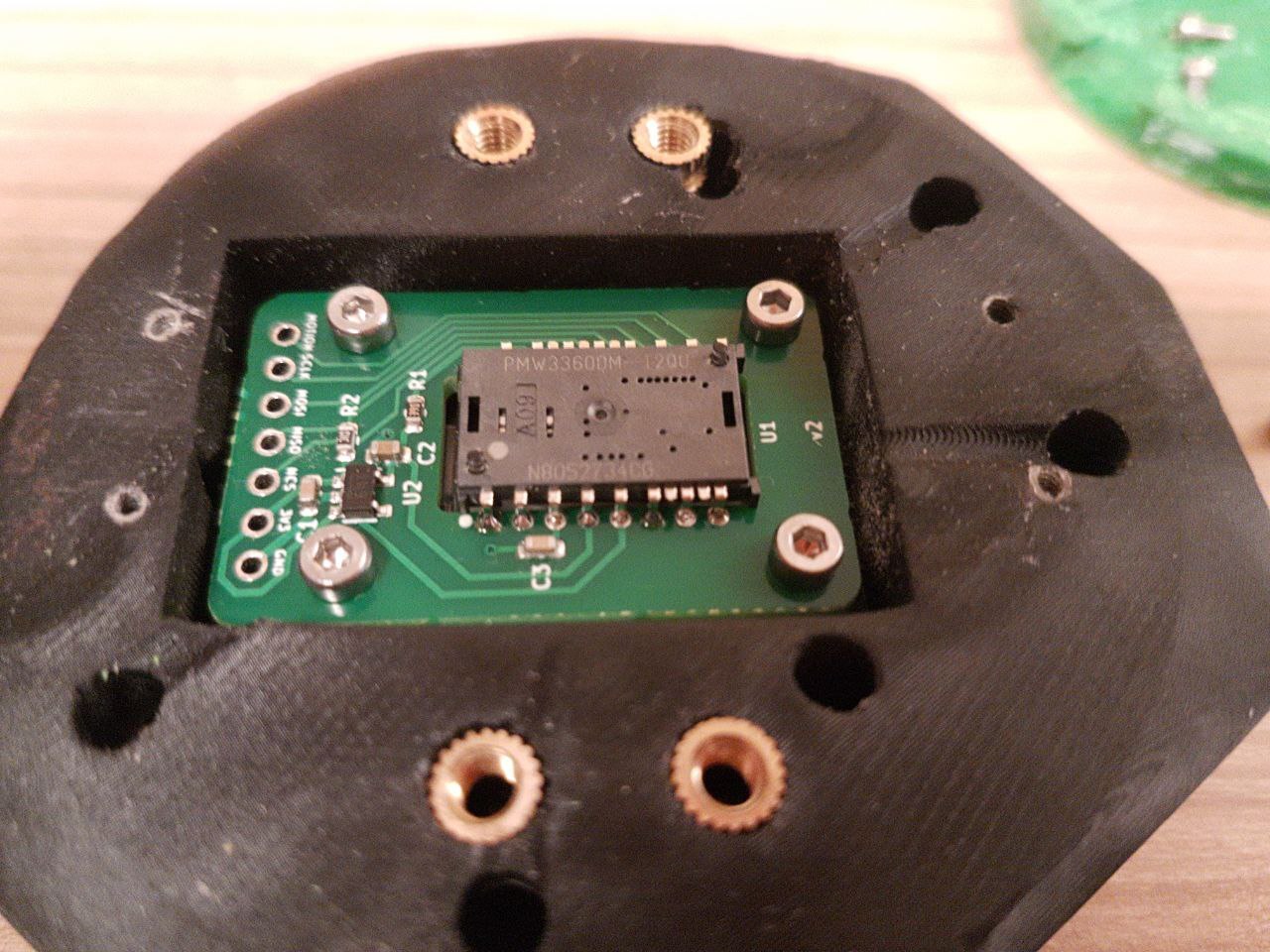

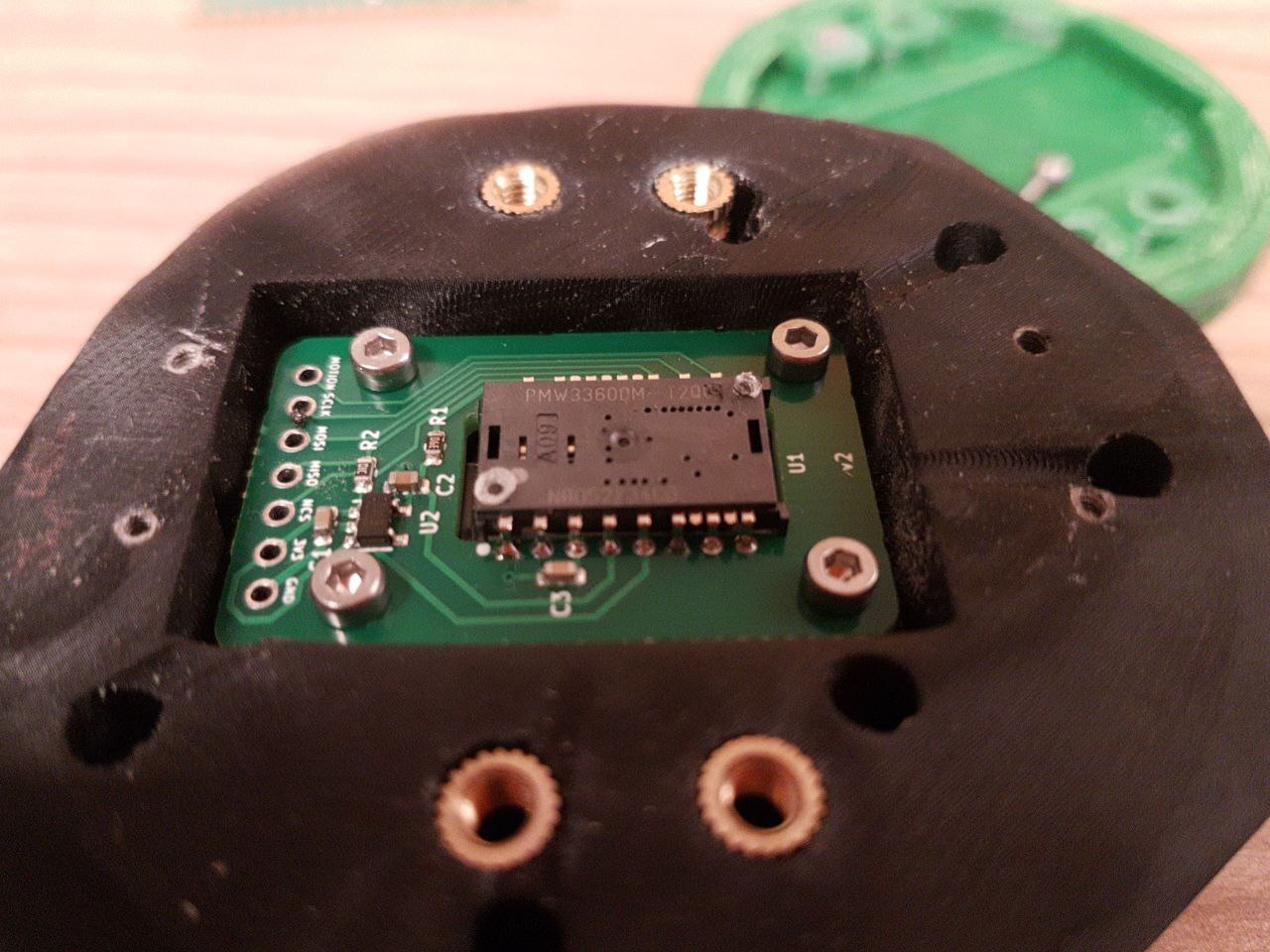

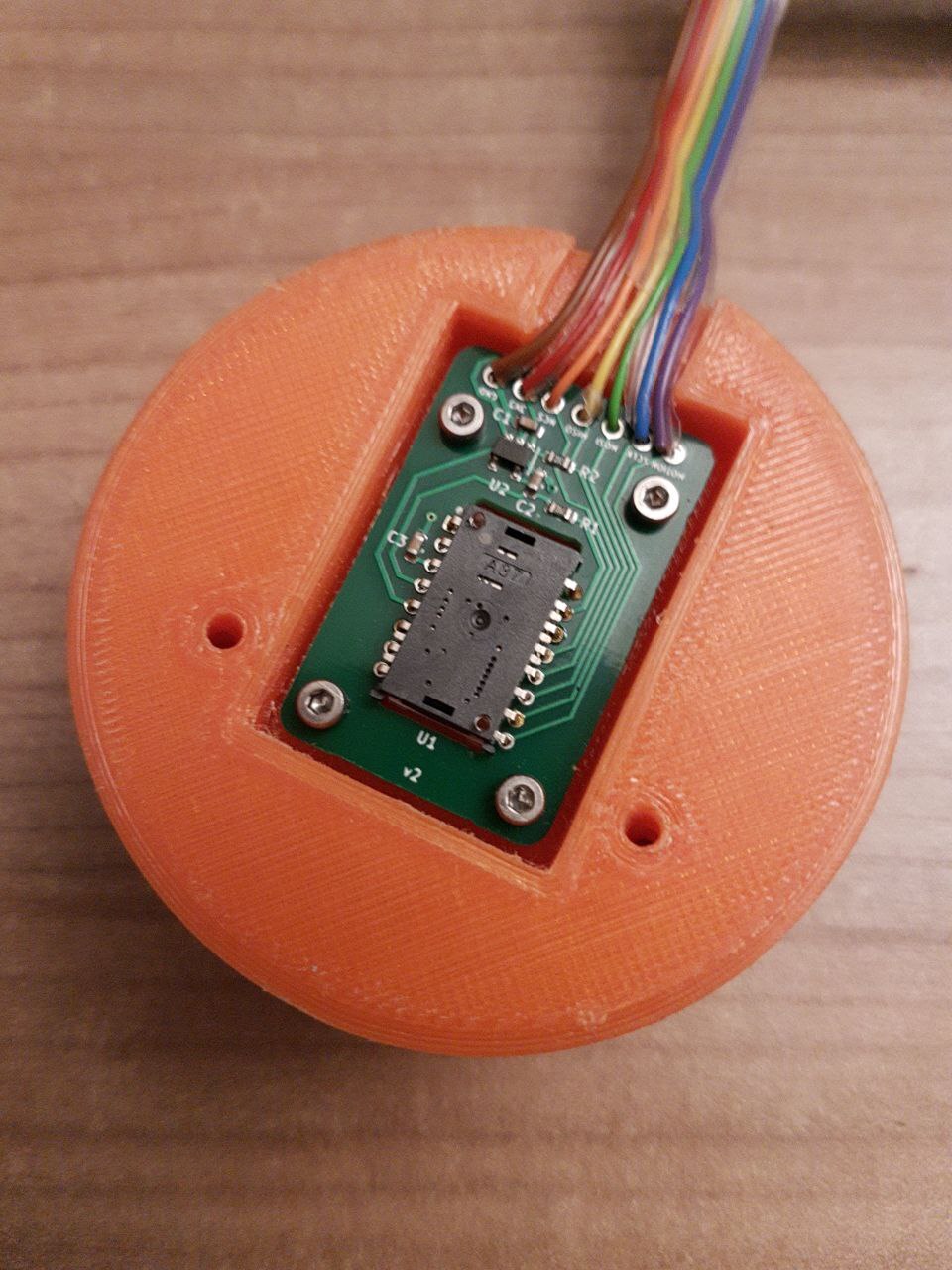

+For some years I have been using Trackballs from Logitech, first the [M570](https://amzn.to/3XhSuRO) and then the [MX Ergo](https://amzn.to/3xdp3pd).

|

|

|

13

|

+But of course we could also build our own!

|

|

|

14

|

+

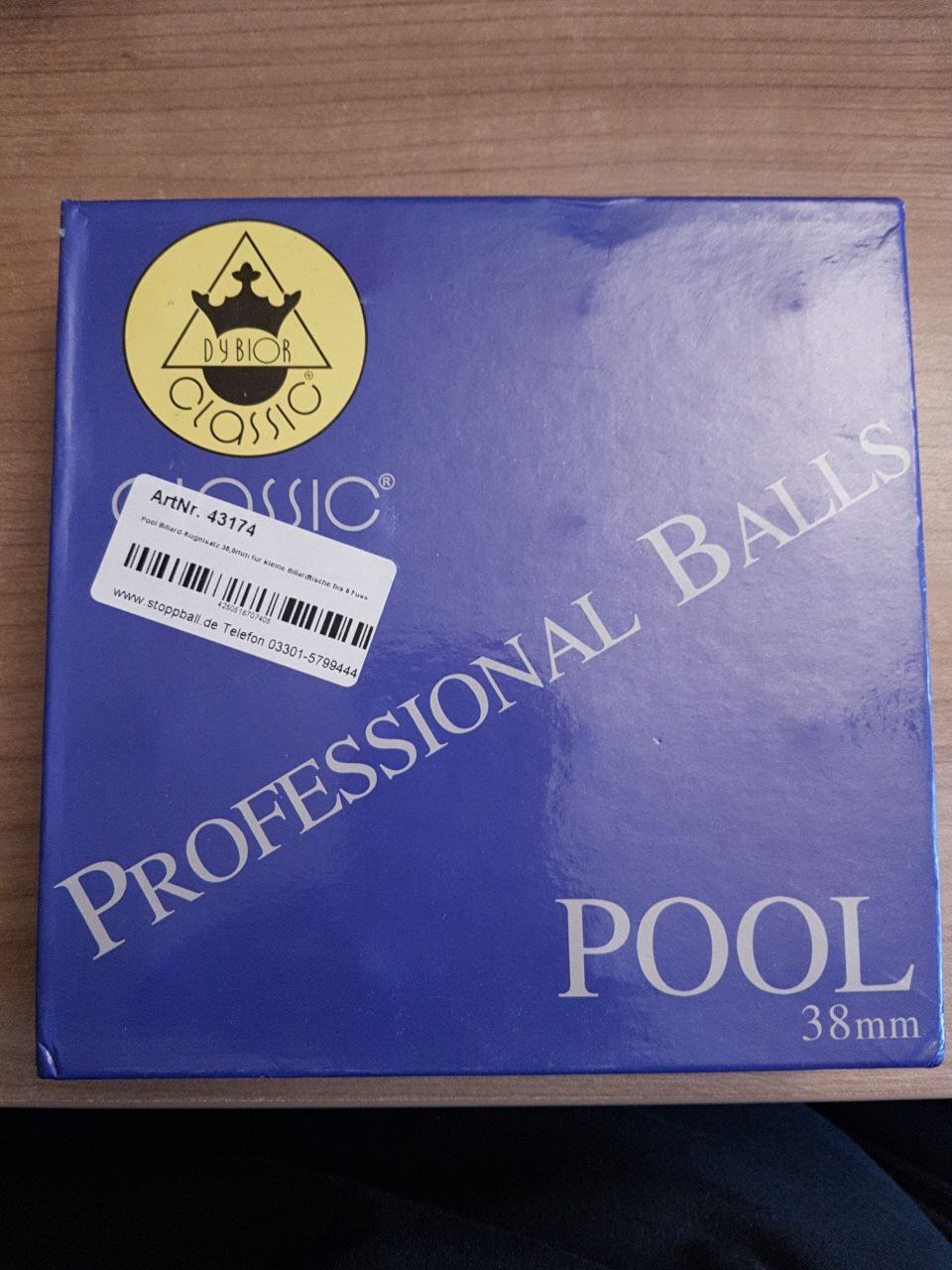

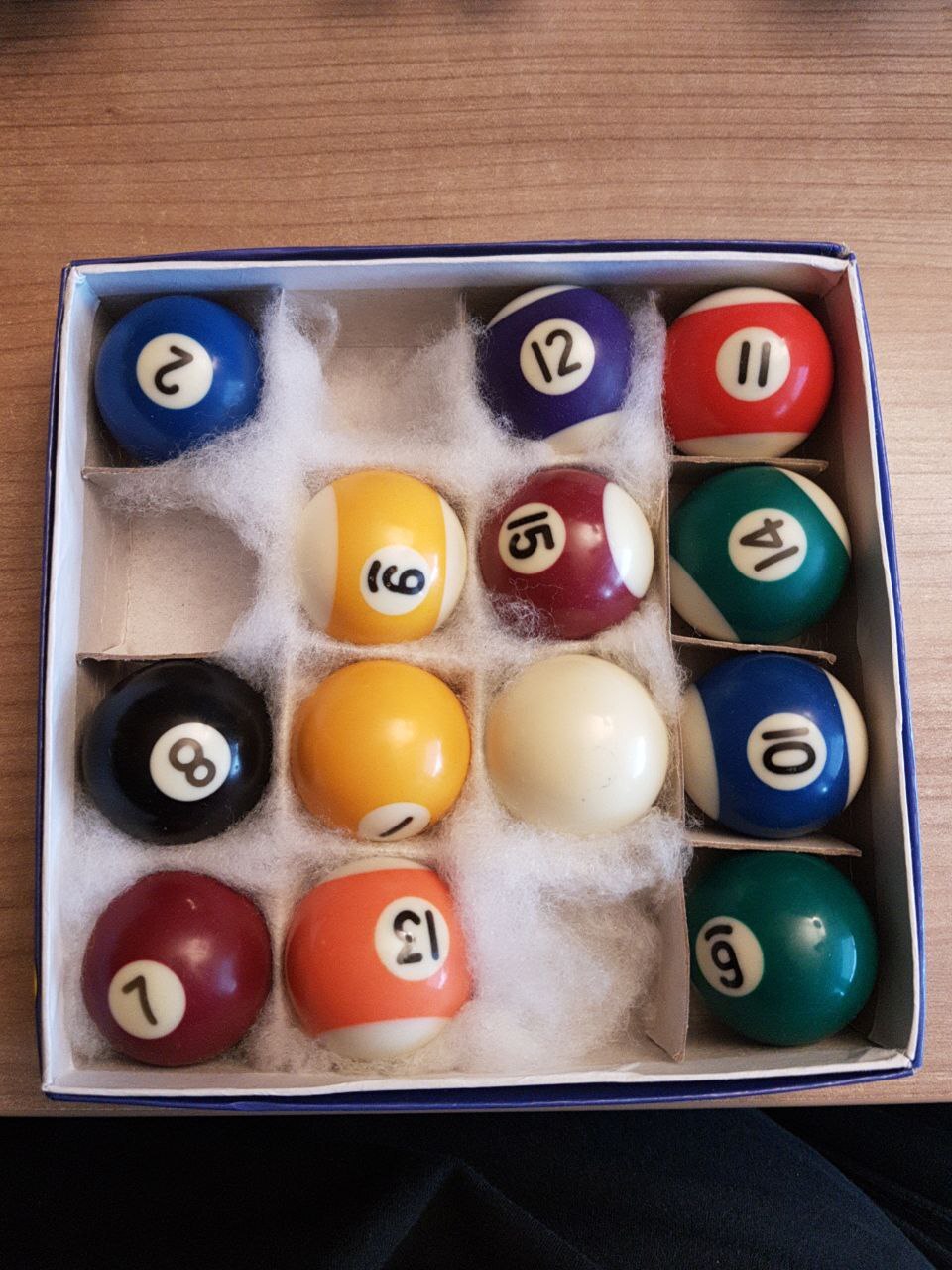

|

|

|

15

|

+So because [Philipp](https://www.phschoen.de/) and I were already looking into building a keyboard with a trackball included, I decided to first get my feet wet by building a stand-alone version.

|

|

|

16

|

+

|

|

|

17

|

+<!--%

|

|

|

18

|

+lightgallery([

|

|

|

19

|

+ [ "img/trackball_v1_27.jpg", "Front of second version" ],

|

|

|

20

|

+ [ "img/trackball_v1_33.jpg", "Inside view of second version" ],

|

|

|

21

|

+ [ "img/trackball_v1_12.jpg", "First completed Trackball" ],

|

|

|

22

|

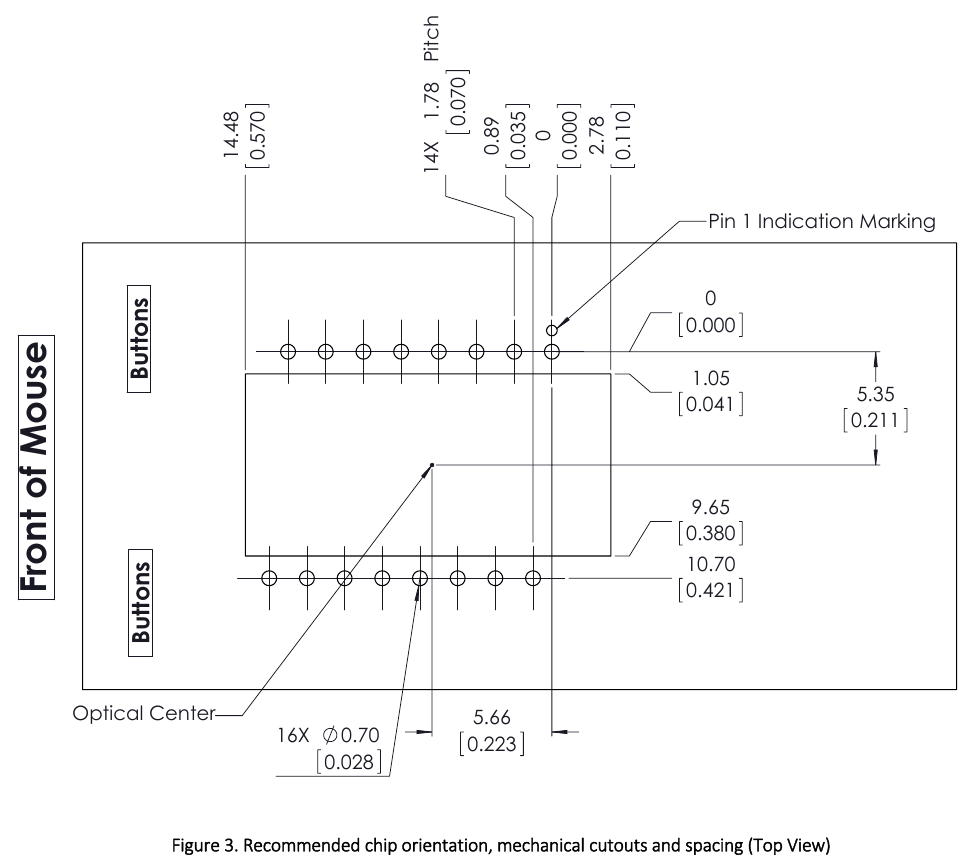

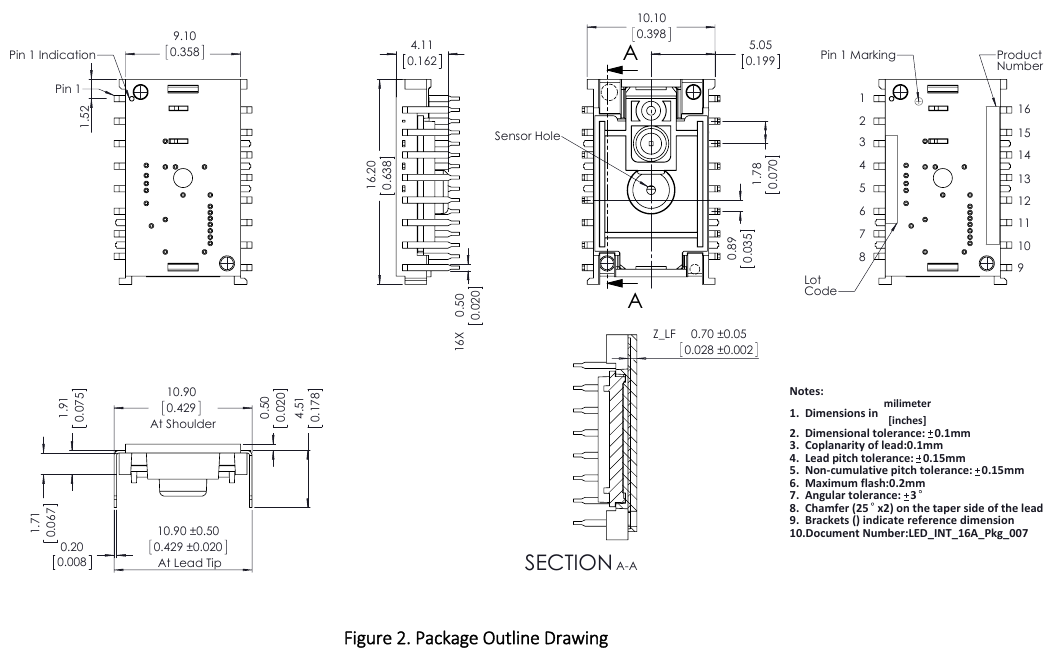

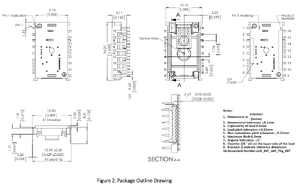

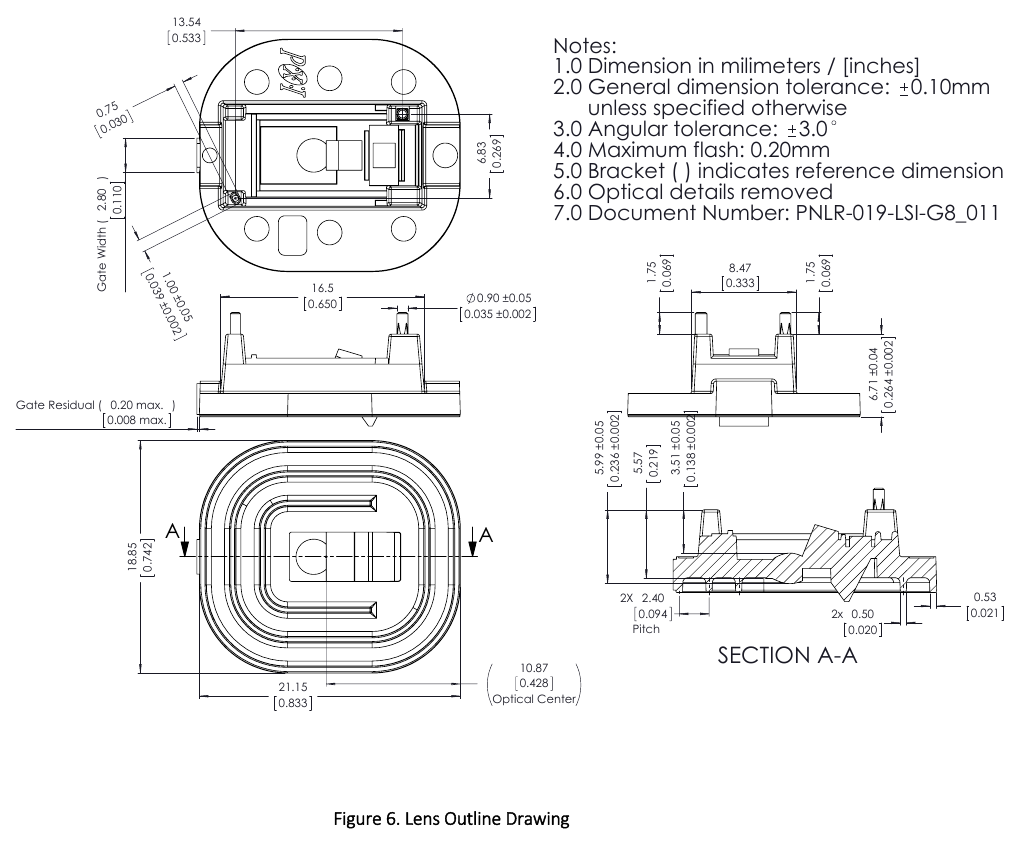

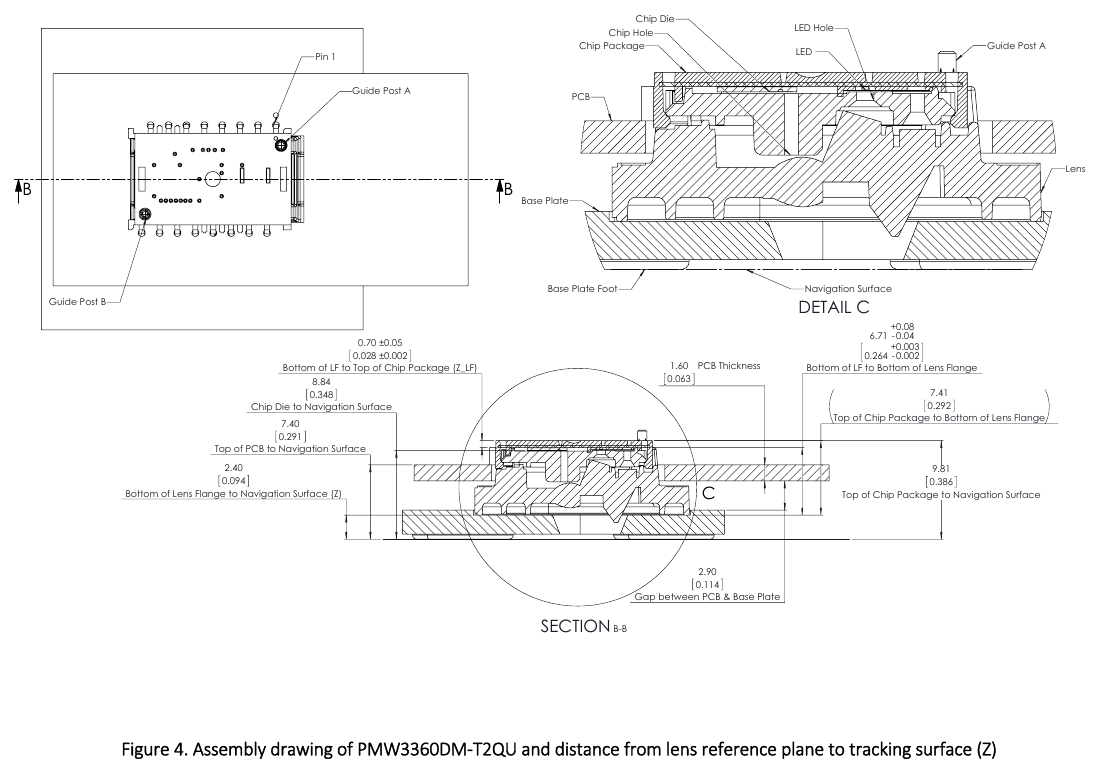

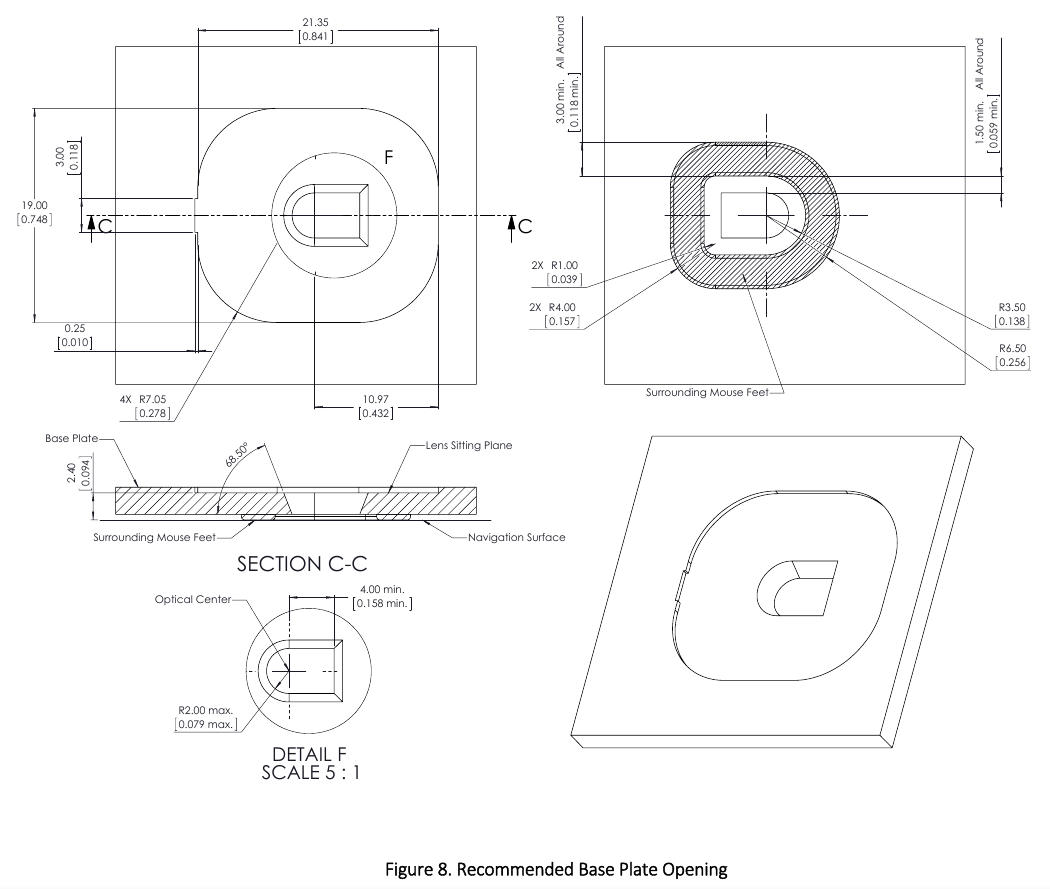

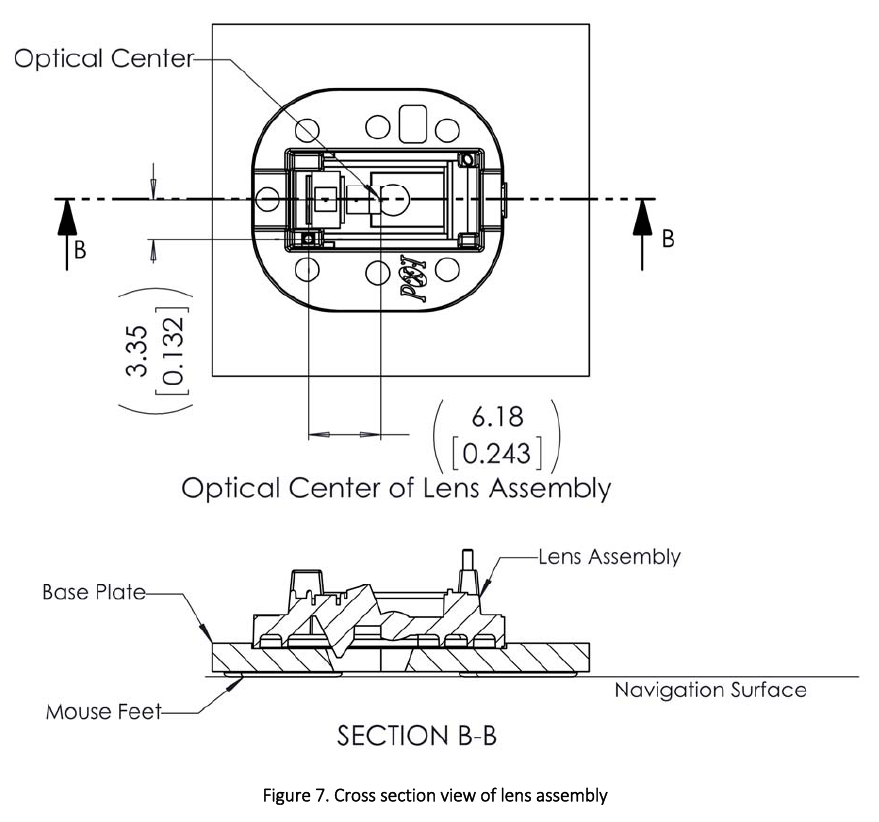

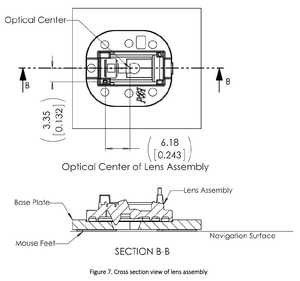

+])

|

|

|

23

|

+%-->

|

|

|

24

|

+

|

|

|

25

|

+It's made with a PMW3360 optical mouse sensor and a Raspberry Pi Pico.

|

|

|

26

|

+The case is 3D printed and was designed in OpenSCAD.

|

|

|

27

|

+

|

|

|

28

|

+<!--%

|

|

|

29

|

+lightgallery([

|

|

|

30

|

+ [ "img/trackball_scad_2.png", "Explosion drawing of assembled parts" ],

|

|

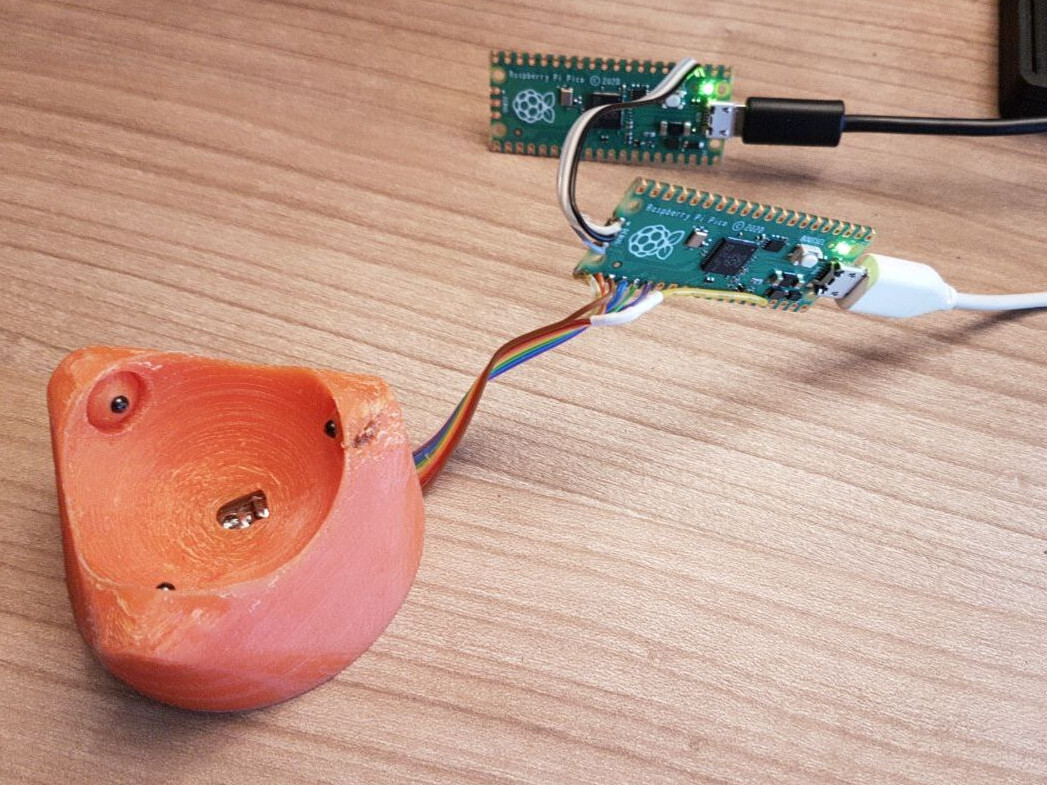

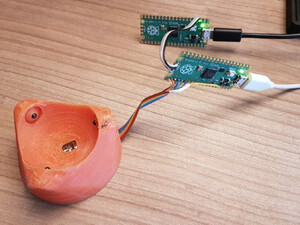

|

31

|

+ [ "img/trackball_scad_1.png", "Close up view of lens distancing and roller holder" ],

|

|

|

32

|

+])

|

|

|

33

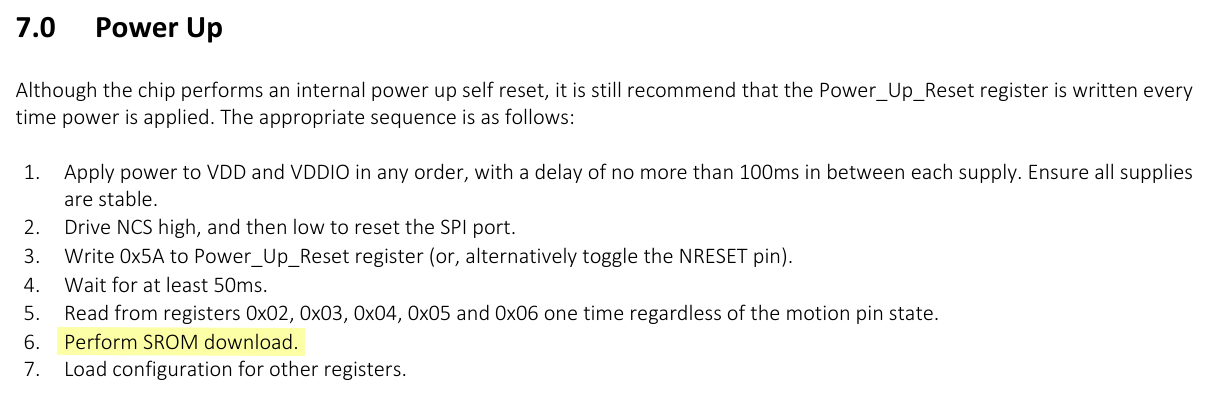

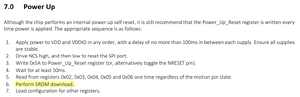

|

+%-->

|

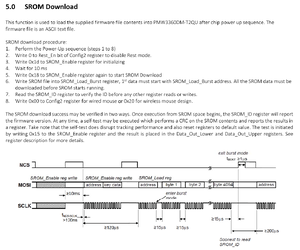

|

|

34

|

+

|

|

|

35

|

+As usual the project is released as free and open-source software / hardware.

|

|

|

36

|

+You can find everything you need to build it yourself in [the git repository](https://git.xythobuz.de/thomas/Trackball)!

|

|

|

37

|

+

|

|

|

38

|

+### Table Of Contents

|

|

|

39

|

+

|

|

|

40

|

+ * [Part Selection](trackball_v1.html#part_selection)

|

|

|

41

|

+ * [3D Design](trackball_v1.html#3d_design)

|

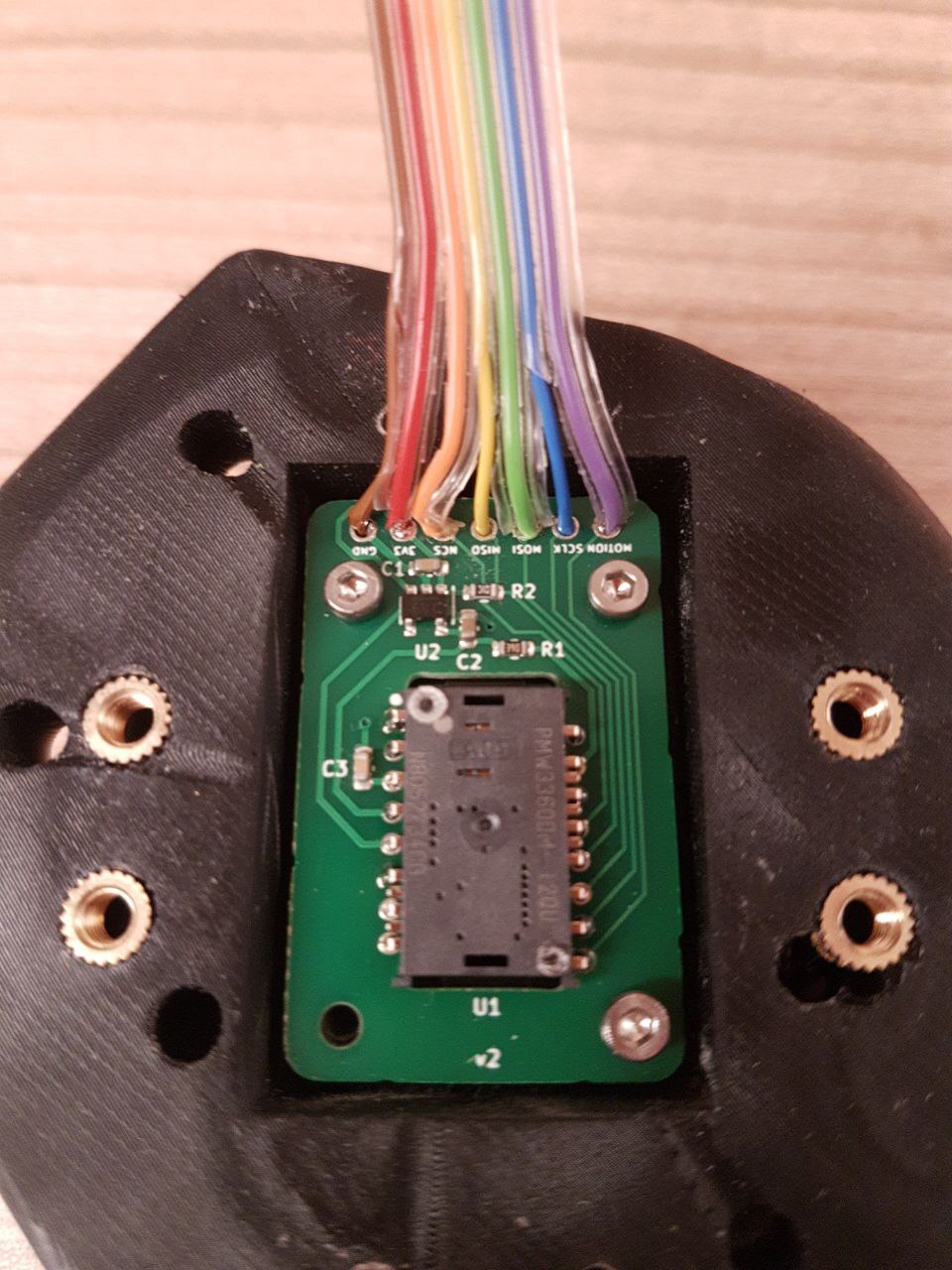

|

|

42

|

+ * [Firmware Development](trackball_v1.html#firmware_devel)

|

|

|

43

|

+ * [Wiring](trackball_v1.html#wiring)

|

|

|

44

|

+ * [Sensor Problems](trackball_v1.html#sensor_problems)

|

|

|

45

|

+ * [First Prototype](trackball_v1.html#first_prototype)

|

|

|

46

|

+ * [Improvements](trackball_v1.html#improvements)

|

|

|

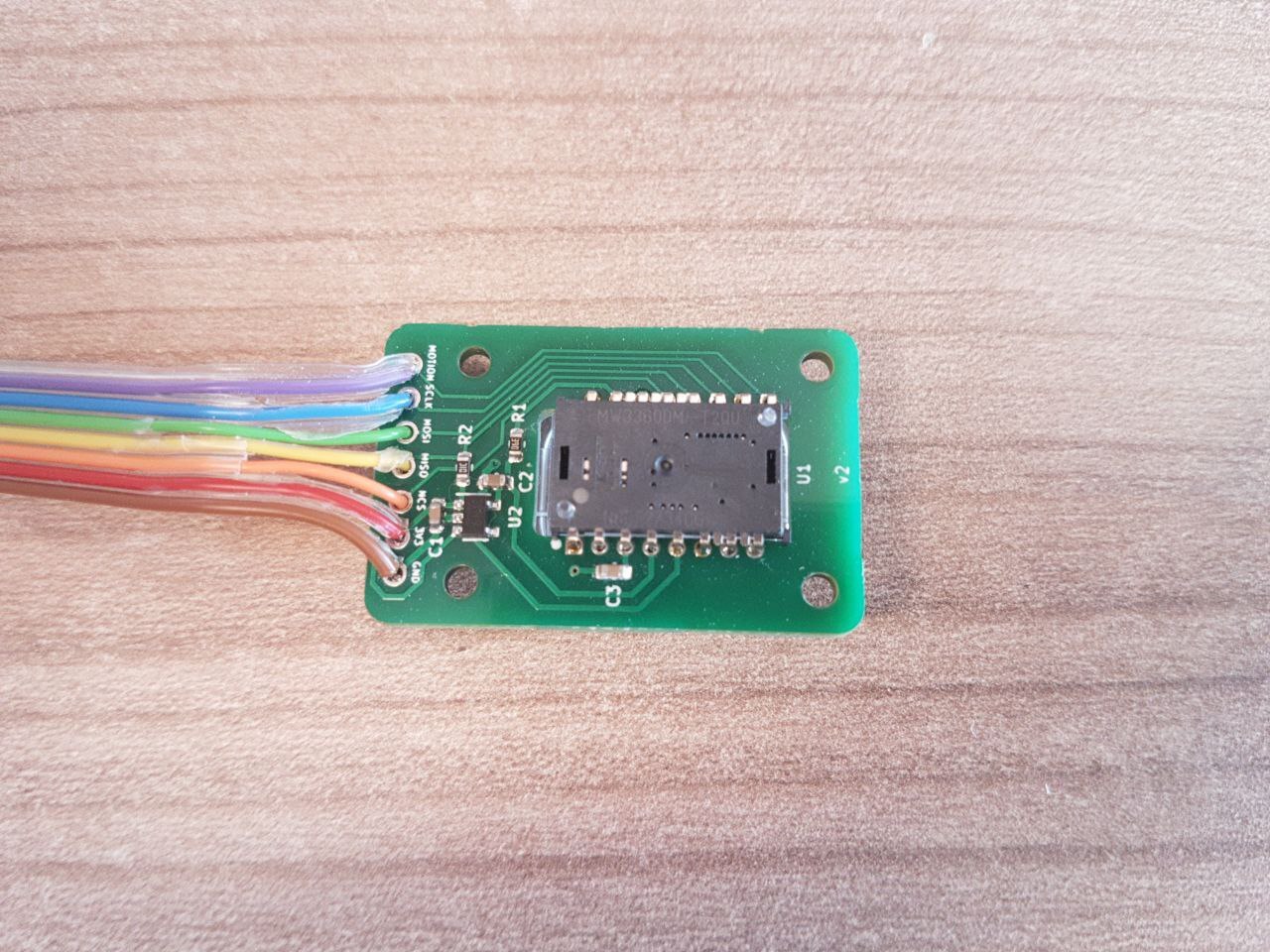

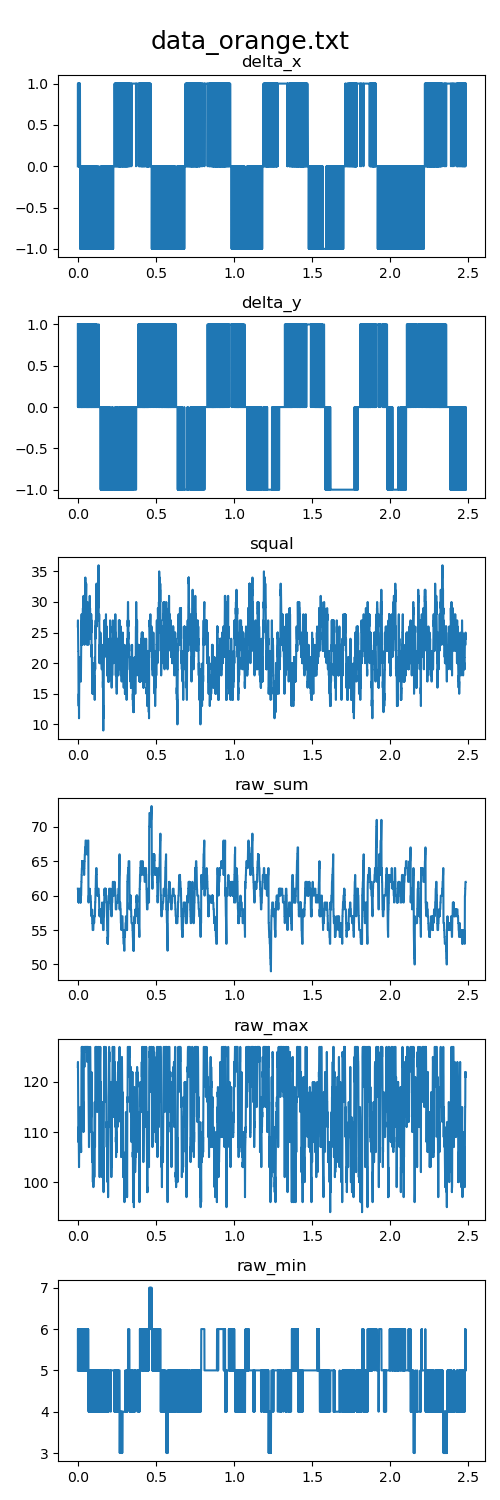

47

|

+ * [User Experience](trackball_v1.html#user_experience)

|

|

|

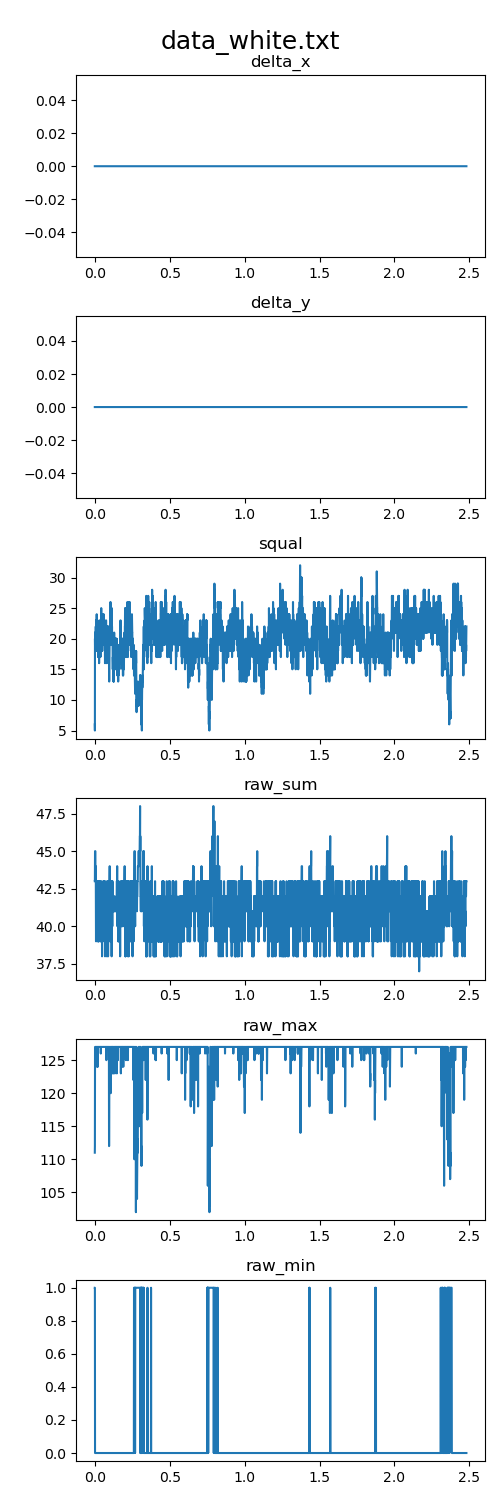

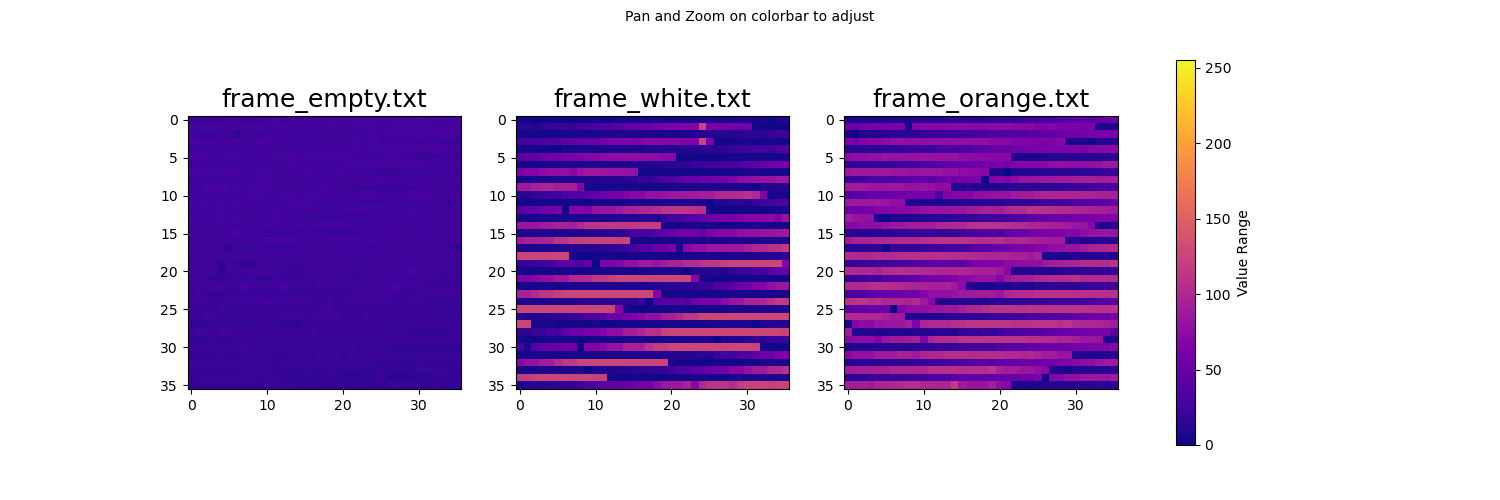

48

|

+ * [License](trackball_v1.html#license)

|

|

|

49

|

+ * [More Pictures](trackball_v1.html#more_pictures)

|

|

|

50

|

+

|

|

|

51

|

+## Part Selection

|

|

|

52

|

+<a class="anchor" name="part_selection"></a>

|

|

|

53

|

+

|

|

|

54

|

+Before embarking on this project some decisions and orders had to be made.

|

|

|

55

|

+

|

|

|

56

|

+To control everything I decided to go with the [Raspberry Pi Pico](https://www.raspberrypi.com/products/raspberry-pi-pico/) / [RP2040](https://www.raspberrypi.com/products/rp2040/) microcontroller board.

|

|

|

57

|

+It is the hot new thing on the block and I wanted to try out both the hardware and the SDK.

|

|

|

58

|

+It's also used extensively in the DIY keyboard community and already has great support in lots of open source software.

|

|

|

59

|

+

|

|

|

60

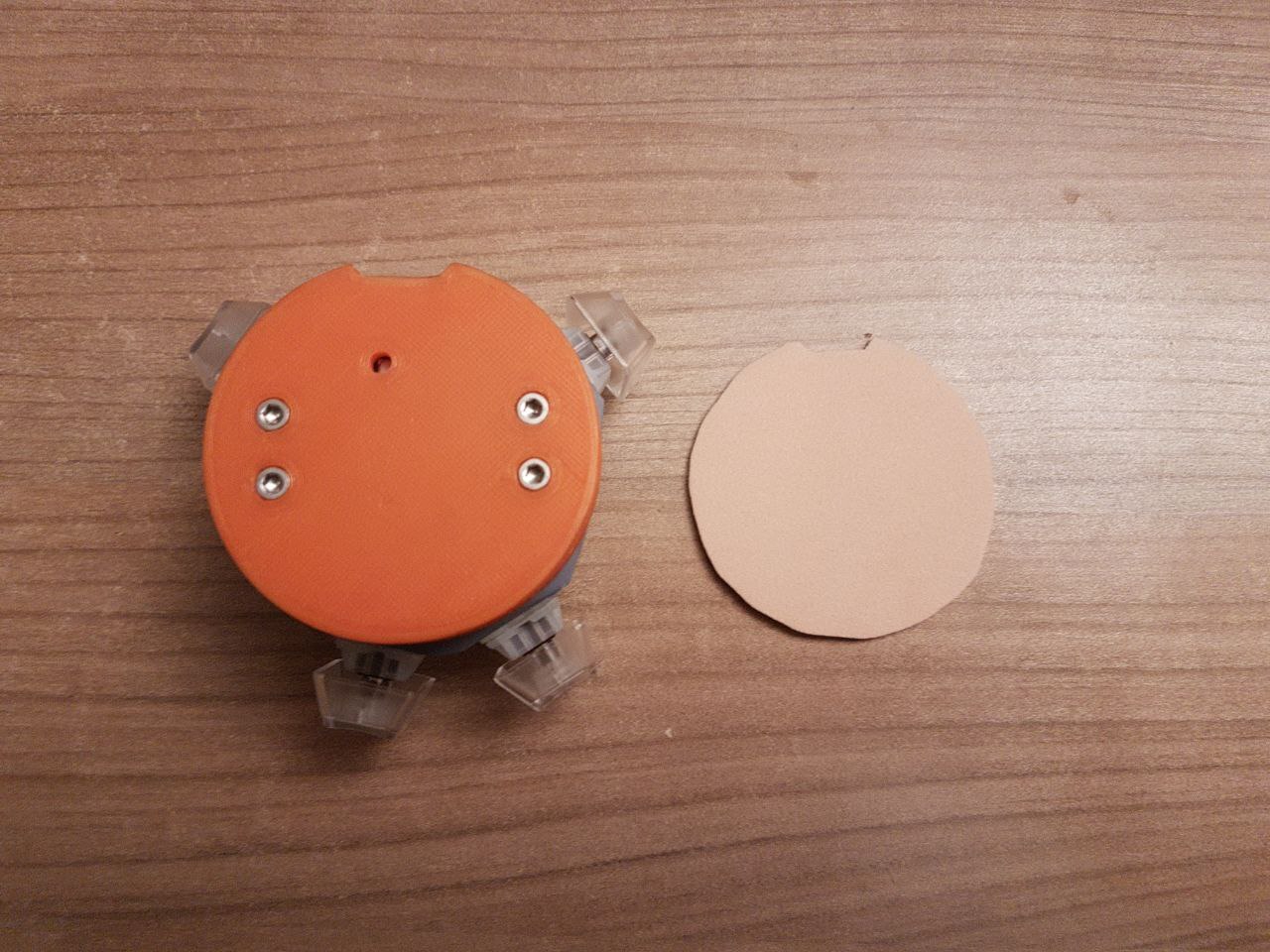

|

+Another big question was which mouse sensor to use.

|

|

|

61

|

+There are different types of sensor, either "optical" using an IR LED, or "laser".

|

|

|

62

|

+Common choices for DIY projects are the [PMW3360](https://www.tindie.com/products/jkicklighter/pmw3360-motion-sensor/) or [PMW3389](https://www.tindie.com/products/jkicklighter/pmw3389-motion-sensor/) optical sensors, or the [ADNS-9800](https://www.tindie.com/products/jkicklighter/adns-9800-laser-motion-sensor/) laser sensor.

|

|

|

63

|

+All of them are available on breakout boards from JACK Enterprises on Tindie.

|

|

|

64

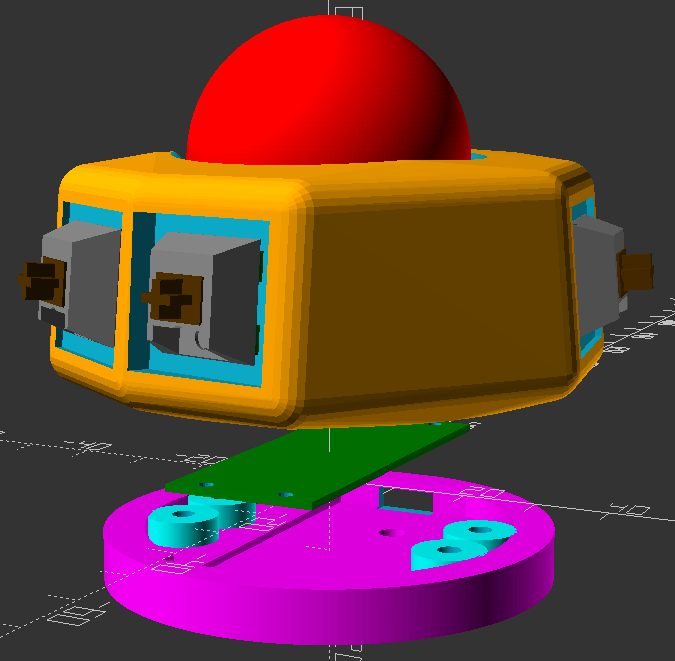

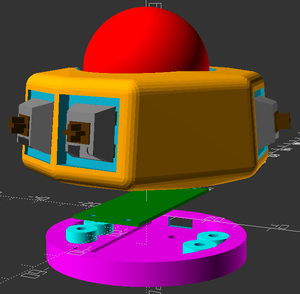

|

+Unfortunately the shipping costs to Europe are very high, so I had to find another solution.

|

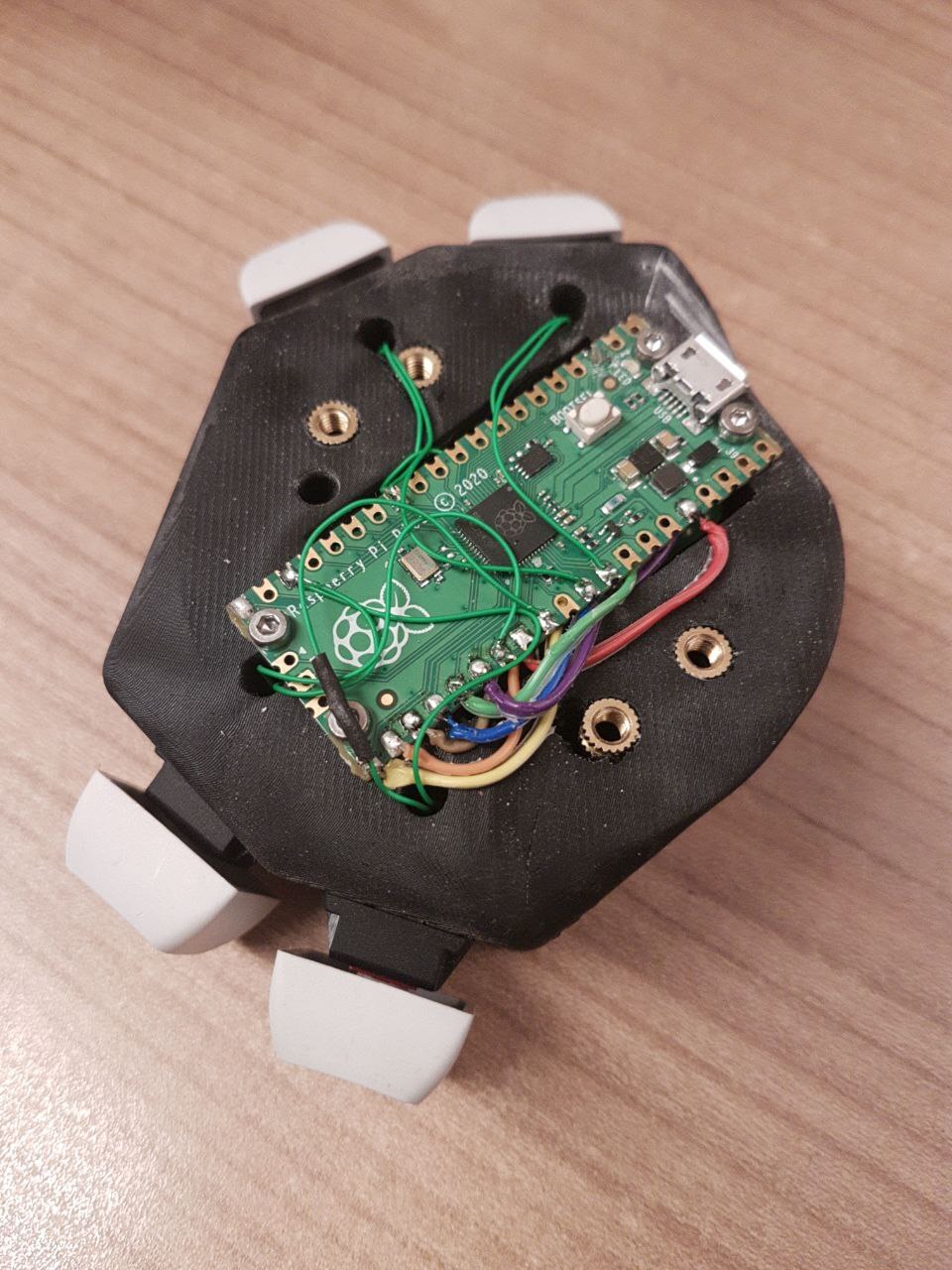

|

|

65

|

+

|

|

|

66

|

+Apparently the requirements for trackballs are not as high as for gaming mouses, they are normally used with much lower resolutions.

|

|

|

67

|

+Because of this, and also because of price and availability, I decided to go for the PMW3360.

|

|

|

68

|

+The chip can be bought on [AliExpress](https://www.aliexpress.com/w/wholesale-pmw3360.html), including the lens assembly, for around 15€.

|

|

|

69

|

+

|

|

|

70

|

+To properly use it also requires some kind of breakout board with a voltage regulator, as the sensor needs ~2V supply voltage.

|

|

|

71

|

+Fortunately the IOs can be used with 3.3V devices like the RP2040.

|

|

|

72

|

+Many designs can be found [on GitHub](https://github.com/search?q=pmw3360), like ["Ogen" from JeremyBois](https://github.com/JeremyBois/Ogen) or ["PMW3360" from kbjunky](https://github.com/kbjunky/PMW3360).

|

|

|

73

|

+

|

|

|

74

|

+I decided to go with ["pmw3360-breakout" by jfedor2](https://github.com/jfedor2/pmw3360-breakout).

|

|

|

75

|

+It is the most minimalistic and it also includes all required files to get the board pre-assembled from [JLCPCB](https://jlcpcb.com/).

|

|

|

76

|

+With their usual promo I got 5 boards produced and assembled for just 15.65€, including shipping.

|

|

|

77

|

+This is unbelievable to me.

|

|

|

78

|

+

|

|

|

79

|

+<!--%

|

|

|

80

|

+lightgallery([

|

|

|

81

|

+ [ "img/pmw3360_order.png", "Screenshot of JLCPCB order" ],

|

|

|

82

|

+ [ "img/pmw3360_breakout_3.jpg", "Top of PMW3360 breakout board" ],

|

|

|

83

|

+ [ "img/pmw3360_breakout_2.jpg", "Bottom of PMW3360 breakout board, with lens" ],

|

|

|

84

|

+])

|

|

|

85

|

+%-->

|

|

|

86

|

+

|

|

|

87

|

+To be able to call this a trackball, we also need some kind of ball or sphere of course.

|

|

|

88

|

+Many people go with the smallest regulation billard balls with a diameter of 38mm.

|

|

|

89

|

+These can be sourced relatively easily and are usualy flat enough, so I got some.

|

|

|

90

|

+This turned out to be a bit of a problem, however, more on that later.

|

|

|

91

|

+

|

|

|

92

|

+<!--%

|

|

|

93

|

+lightgallery([

|

|

|

94

|

+ [ "img/trackball_v1_16.jpg", "Small billard balls, case" ],

|

|

|

95

|

+ [ "img/trackball_v1_17.jpg", "Small billard balls" ],

|

|

|

96

|

+])

|

|

|

97

|

+%-->

|

|

|

98

|

+

|

|

|

99

|

+To get the ball rolling smoothly we also need some kind of mount or bearing surface.

|

|

|

100

|

+There are different options for this, nicely detailed on [Reddit](https://www.reddit.com/r/ErgoMechKeyboards/comments/yyu4ra/trackball_bearings_a_comparison_of_cheap_rollers/) and [GitHub](https://github.com/Wimads/Trackball-mousekeys-add-on-for-Skeletyl) by "Wimads".

|

|

|

101

|

+Because of this I decided to go with Si3N4 static bearing balls with a diameter of 3mm.

|

|

|

102

|

+I got 20 [from eBay](https://www.ebay.de/itm/304376943632?var=603428120198) for ~5€.

|

|

|

103

|

+

|

|

|

104

|

+For the switches I decided to go with Cherry MX keyboard switches, simply because I had them available.

|

|

|

105

|

+They are not optimal with their long key travel, I plan to change it in the future, but you also kinda get used to them.

|

|

|

106

|

+

|

|

|

107

|

+<!--%

|

|

|

108

|

+tableHelper([ "align-right", "align-right", "align-last-right", "align-right monospaced"],

|

|

|

109

|

+ [ "Part", "Count", "Description", "Cost" ], [

|

|

|

110

|

+ [ "µC", "1x", ("Raspberry Pi Pico", "https://www.raspberrypi.com/products/raspberry-pi-pico/"), "4.10€" ],

|

|

|

111

|

+ [ "Sensor", "1x", ("PMW3360 (chip and lens)", "https://www.aliexpress.com/item/4000904265601.html"), "11.83€" ],

|

|

|

112

|

+ [ "PCB", "1x", ("PMW3360 Breakout Board", "https://github.com/jfedor2/pmw3360-breakout"), "3.13€" ],

|

|

|

113

|

+ [ "Ball", "1x", ("38mm billard ball", "https://www.ebay.de/itm/222457101403"), "1.37€" ],

|

|

|

114

|

+ [ "Bearing", "3x", ("Si3N4 3mm sphere", "https://www.ebay.de/itm/304376943632?var=603428120198"), "0.72€" ],

|

|

|

115

|

+ [ "Switch", "4x", ("Cherry MX compatible", "https://www.aliexpress.com/item/1005003803920093.html"), "1.03€" ],

|

|

|

116

|

+ [ "Keycap", "4x", "From old keycap set", "0.00€" ],

|

|

|

117

|

+ [ "Insert", "4x", "M3 od=5mm l=6mm", "0.00€" ],

|

|

|

118

|

+ [ "Screw", "4x", "M3 l=8mm", "0.00€" ],

|

|

|

119

|

+ [ "Screw", "8x", "M2 l=6mm", "0.00€" ],

|

|

|

120

|

+ [ "Screw", "3x", "Grub screw M3 l>=4mm", "0.00€" ],

|

|

|

121

|

+ [ "", "", "Sum", "22.18€" ]

|

|

|

122

|

+ ]

|

|

|

123

|

+)

|

|

|

124

|

+%-->

|

|

|

125

|

+

|

|

|

126

|

+*Note*: some parts are only sold in bulk.

|

|

|

127

|

+Therefore, if you only want to build a single trackball, it will be more expensive than the sum listed above.

|

|

|

128

|

+What you see on top is the actual price I paid for the parts, reduced to the amount required for a single device.

|

|

|

129

|

+Also some parts, like screws or 3D printing materials, I consider as normal parts of a workshop, so they are not added to the cost either.

|

|

|

130

|

+

|

|

|

131

|

+## 3D Design

|

|

|

132

|

+<a class="anchor" name="3d_design"></a>

|

|

|

133

|

+

|

|

|

134

|

+The most important part of the 3D design is the mounting of the sensor and lens assembly in relation to the tracking surface, in our case the ball.

|

|

|

135

|

+The datasheet has lots of dimensional drawings which kind of hide all the important measurements somewhere in there.

|

|

|

136

|

+

|

|

|

137

|

+<!--%

|

|

|

138

|

+lightgallery([

|

|

|

139

|

+ [ "img/pmw3360_dimensions_1.png", "PMW3360 dimensional drawings, 1/6" ],

|

|

|

140

|

+ [ "img/pmw3360_dimensions_2.png", "PMW3360 dimensional drawings, 2/6" ],

|

|

|

141

|

+ [ "img/pmw3360_dimensions_3.png", "PMW3360 dimensional drawings, 3/6" ],

|

|

|

142

|

+])

|

|

|

143

|

+%-->

|

|

|

144

|

+

|

|

|

145

|

+I took great care and tried to design everything according to the specifications.

|

|

|

146

|

+

|

|

|

147

|

+<!--%

|

|

|

148

|

+lightgallery([

|

|

|

149

|

+ [ "img/pmw3360_dimensions_4.png", "PMW3360 dimensional drawings, 4/6" ],

|

|

|

150

|

+ [ "img/pmw3360_dimensions_5.png", "PMW3360 dimensional drawings, 5/6" ],

|

|

|

151

|

+ [ "img/pmw3360_dimensions_6.png", "PMW3360 dimensional drawings, 6/6" ],

|

|

|

152

|

+])

|

|

|

153

|

+%-->

|

|

|

154

|

+

|

|

|

155

|

+The static bearing balls are push-fit mounted inside the "roller holders".

|

|

|

156

|

+Printing this part is a bit tricky.

|

|

|

157

|

+Including the ball it should have a total height of 10mm.

|

|

|

158

|

+With my FDM printer it was 0.1mm too small, so I added an adjustment parameter in the design.

|

|

|

159

|

+Later iterations were always printed on SLA printers, where the adjustment had to be set back to zero.

|

|

|

160

|

+

|

|

|

161

|

+So if you want the distance to be perfect, measure the printed and assembled part and adjust accordingly.

|

|

|

162

|

+Although I think small deviations shouldn't matter too much.

|

|

|

163

|

+The sensor has a relatively large range of useable distances.

|

|

|

164

|

+

|

|

|

165

|

+<!--%

|

|

|

166

|

+lightgallery([

|

|

|

167

|

+ [ "img/trackball_scad_2.png", "Explosion drawing of assembled parts" ],

|

|

|

168

|

+ [ "img/trackball_scad_1.png", "Close up view of lens distancing and roller holder" ],

|

|

|

169

|

+])

|

|

|

170

|

+%-->

|

|

|

171

|

+

|

|

|

172

|

+The roller holders are kept in place with a grub screw for each.

|

|

|

173

|

+Then the sensor can be screwed into the top housing first, followed by the Pi.

|

|

|

174

|

+The bottom part is just a lid, without any parts screwed into it.

|

|

|

175

|

+

|

|

|

176

|

+Unfortunately the design is relatively unwieldy in OpenSCAD.

|

|

|

177

|

+Even the preview render takes dozens of seconds, with a very sluggish UI afterwards.

|

|

|

178

|

+Rendering takes ¾ of an hour on my machine.

|

|

|

179

|

+For development the `$fn` parameter can be set to a lower value.

|

|

|

180

|

+That helps somewhat.

|

|

|

181

|

+

|

|

|

182

|

+## Firmware Development

|

|

|

183

|

+<a class="anchor" name="firmware_devel"></a>

|

|

|

184

|

+

|

|

|

185

|

+Before designing and printing the complete device I made a small test bed to hold the sensor and ball.

|

|

|

186

|

+

|

|

|

187

|

+<!--%

|

|

|

188

|

+lightgallery([

|

|

|

189

|

+ [ "img/trackball_v1_1.jpg", "First sensor case prototype, with ball" ],

|

|

|

190

|

+ [ "img/trackball_v1_2.jpg", "First sensor case prototype, no ball" ],

|

|

|

191

|

+ [ "img/trackball_v1_3.jpg", "Sensor in first case prototype" ],

|

|

|

192

|

+])

|

|

|

193

|

+%-->

|

|

|

194

|

+

|

|

|

195

|

+With this initial "engineering sample" built I could continue with development of the firmware.

|

|

|

196

|

+This was basically my christmas holiday project in 2022.

|

|

|

197

|

+

|

|

|

198

|

+Interfacing with the PMW3360 chip is a bit more difficult than I initially expected.

|

|

|

199

|

+Of course everything is confidential and proprietary, but you can find [leaked datasheets on the internet](https://d3s5r33r268y59.cloudfront.net/datasheets/9604/2017-05-07-18-19-11/PMS0058-PMW3360DM-T2QU-DS-R1.50-26092016._20161202173741.pdf).

|

|

|

200

|

+It describes everything pretty well, including pinout and electrical characteristics, which were already taken care of in the breakout board.

|

|

|

201

|

+And it also describes the SPI communication interface.

|

|

|

202

|

+The only problematic part is the so-called SROM.

|

|

|

203

|

+

|

|

|

204

|

+<!--%

|

|

|

205

|

+lightgallery([

|

|

|

206

|

+ [ "img/pmw3360_datasheet_1.png", "Excerpt of PMW3360 datasheet, Power Up" ],

|

|

|

207

|

+ [ "img/pmw3360_datasheet_2.png", "Excerpt of PMW3360 datasheet, SROM Download" ],

|

|

|

208

|

+])

|

|

|

209

|

+%-->

|

|

|

210

|

+

|

|

|

211

|

+The chip requires a binary blob to be loaded on every power up, otherwise it won't work.

|

|

|

212

|

+Fortunately this was also leaked or sniffed (I'm not sure), version 4 is available [here](https://github.com/mrjohnk/PMW3360DM-T2QU/blob/master/Arduino%20Examples/PMW3360DM-polling/SROM_0x04_Arduino.ino) or [here](https://github.com/SunjunKim/PMW3360/blob/master/src/PMW3360.cpp), for example.

|

|

|

213

|

+So I've included it in my firmware as well.

|

|

|

214

|

+Not all of the fancy functionality is included in this V4 firmware blob, but it is enough for normal mouse operation.

|

|

|

215

|

+

|

|

|

216

|

+Contrary to that I'm very happy with the RP2040 / Raspberry Pi Pico ecosystem.

|

|

|

217

|

+The hardware seems well documented without having to go completely in-depth into the CPU datasheets.

|

|

|

218

|

+And the SDK similarly seems well thought-out and implemented.

|

|

|

219

|

+

|

|

|

220

|

+I was especially delighted with the ability to simply use a second Pico as a debugging dongle instead of needing an ST-Link or similar hardware.

|

|

|

221

|

+

|

|

|

222

|

+<!--%

|

|

|

223

|

+lightgallery([

|

|

|

224

|

+ [ "img/trackball_v1_4.jpg", "Debugging with two Pi Picos" ],

|

|

|

225

|

+])

|

|

|

226

|

+%-->

|

|

|

227

|

+

|

|

|

228

|

+For the USB device implementation the Pico SDK includes [TinuyUSB](https://github.com/hathach/tinyusb).

|

|

|

229

|

+From the Pico SDK I based my work on their [HID Composite example](https://github.com/raspberrypi/pico-examples/tree/master/usb/device/dev_hid_composite) ported from TinyUSB, as well as the [CDC MSC example](https://github.com/hathach/tinyusb/tree/master/examples/device/cdc_msc) directly from TinyUSB.

|

|

|

230

|

+

|

|

|

231

|

+This was very comfortable to use.

|

|

|

232

|

+From [a past project](2015_12_20_serialgamepad.html) I'm familiar with the pain of writing custom USB HID descriptors.

|

|

|

233

|

+Fortunately this is all handled by TinyUSB.

|

|

|

234

|

+You just need to pass the appropriate delta values for the mouse axes.

|

|

|

235

|

+

|

|

|

236

|

+I combined the examples to have the device act simultaneously as a human input device, and serial port and mass storage device for debugging.

|

|

|

237

|

+Of course I only developed and tested the device on my Linux machines initially.

|

|

|

238

|

+But I have now also tested it with Windows, and it works fine there as well.

|

|

|

239

|

+All functionality can be accessed without any driver installation.

|

|

|

240

|

+

|

|

|

241

|

+For the debug mass storage I also had to add some kind of file system.

|

|

|

242

|

+To do this I used [the FatFs library](https://github.com/abbrev/fatfs).

|

|

|

243

|

+I simply reserved a bunch of memory in RAM that acts as the disk device.

|

|

|

244

|

+Before it is mounted by the user, the disk is formatted and filled with the required data.

|

|

|

245

|

+Then the host can mount it and read the files.

|

|

|

246

|

+

|

|

|

247

|

+## Wiring

|

|

|

248

|

+<a class="anchor" name="wiring"></a>

|

|

|

249

|

+

|

|

|

250

|

+Wiring up the device is very easy, especially because the RP2040 provides great flexibility in its use of the GPIOs and the hardware periphery, in our case SPI.

|

|

|

251

|

+

|

|

|

252

|

+<!--%

|

|

|

253

|

+lightgallery([

|

|

|

254

|

+ [ "img/pi_pico_pinout.png", "Raspberry Pi Pico pinout" ],

|

|

|

255

|

+])

|

|

|

256

|

+%-->

|

|

|

257

|

+

|

|

|

258

|

+The SPI interface of the PMW3360 needs to be connected to one of the SPI interfaces of the Pico.

|

|

|

259

|

+But which one you use is not important and can easily be changed in the code.

|

|

|

260

|

+By default it uses the standard SPI0 pins.

|

|

|

261

|

+

|

|

|

262

|

+<div class="textwrap"><pre>

|

|

|

263

|

+GPIO 16 (pin 21) MISO -> MISO on PMW3360 board

|

|

|

264

|

+GPIO 17 (pin 22) CS -> NCS on PMW3360 board

|

|

|

265

|

+GPIO 18 (pin 24) SCK -> SCK on PMW3360 board

|

|

|

266

|

+GPIO 19 (pin 25) MOSI -> MOSI on PMW3360 board

|

|

|

267

|

+GPIO 20 (pin 26) -> MOTION on PMW3360 board

|

|

|

268

|

+ 3.3v (pin 36) -> VCC on PMW3360 board

|

|

|

269

|

+ GND (pin 38) -> GND on PMW3360 board

|

|

|

270

|

+GPIO 21 (pin 27) -> Switch (back button)

|

|

|

271

|

+GPIO 22 (pin 29) -> Switch (middle button)

|

|

|

272

|

+GPIO 26 (pin 31) -> Switch (left button)

|

|

|

273

|

+GPIO 27 (pin 32) -> Switch (right button)

|

|

|

274

|

+</pre></div>

|

|

|

275

|

+

|

|

|

276

|

+The switches use the internal pull-up resistors in the RP2040 GPIOs.

|

|

|

277

|

+So they should be wired active-low, with their common connection to GND.

|

|

|

278

|

+

|

|

|

279

|

+## Sensor Problems

|

|

|

280

|

+<a class="anchor" name="sensor_problems"></a>

|

|

|

281

|

+

|

|

|

282

|

+With the firmware mostly done I hoped to be able to use the device immediately.

|

|

|

283

|

+But it didn't quite work.

|

|

|

284

|

+When I ran my finger over the lens the sensor moved erratically, but no movement was seen with the white ball I initially tested with.

|

|

|

285

|

+Only after switching to other colors I noticed that they behave differently.

|

|

|

286

|

+So there was some investigation required.

|

|

|

287

|

+

|

|

|

288

|

+Besides the X and Y values you get a bunch of other stuff with each sensor data sample.

|

|

|

289

|

+I added functionality to dump these and made a small Python script to visualize them.

|

|

|

290

|

+

|

|

|

291

|

+<!--%

|

|

|

292

|

+lightgallery([

|

|

|

293

|

+ [ "img/pmw3360_data_white.png", "Data capture of white ball" ],

|

|

|

294

|

+ [ "img/pmw3360_data_orange.png", "Data capture of orange ball" ],

|

|

|

295

|

+])

|

|

|

296

|

+%-->

|

|

|

297

|

+

|

|

|

298

|

+With the white ball you see no movement at all, with the right ball there is movement, but there is no immediately obvious difference in the other datapoints.

|

|

|

299

|

+

|

|

|

300

|

+The PMW3360 also has a "Frame Capture" mode.

|

|

|

301

|

+This can be used to grab a full picture of what the image sensor is seeing.

|

|

|

302

|

+Using it overwrites the SROM firmware, so the sensor has to be re-initialized afterwards.

|

|

|

303

|

+I had some problems with this mode.

|

|

|

304

|

+For some reason I'm not able to properly reset the sensor after capturing a frame.

|

|

|

305

|

+It no longer reports the correct SROM ID and only a power-cycle fixes it.

|

|

|

306

|

+But the frame data can be read properly and I made a Python script to visualize it.

|

|

|

307

|

+

|

|

|

308

|

+<!--%

|

|

|

309

|

+lightgallery([

|

|

|

310

|

+ [ "img/pmw3360_frames.png", "Frame capture with no ball, white ball and orange ball" ],

|

|

|

311

|

+])

|

|

|

312

|

+%-->

|

|

|

313

|

+

|

|

|

314

|

+I'm not sure what exactly is going on with the strange lines visible in the pictures.

|

|

|

315

|

+I can't find any bug on the visualization side, but I won't rule that out fully.

|

|

|

316

|

+But like with the data visualization above, there is no obvious difference between the different colored balls.

|

|

|

317

|

+

|

|

|

318

|

+While producing some pretty pictures, this approach of analyzing the data didn't really bring us any closer to a working trackball.

|

|

|

319

|

+

|

|

|

320

|

+But then Philipp had the idea that saved the day.

|

|

|

321

|

+From the factory the PMW3360 sensors come with two small pieces of kapton tape over the optical inlet and outlet holes in the chip package.

|

|

|

322

|

+Removing them solved all issues.

|

|

|

323

|

+

|

|

|

324

|

+<!--%

|

|

|

325

|

+lightgallery([

|

|

|

326

|

+ [ "img/pmw3360_breakout_1.jpg", "Bottom of PMW3360 breakout board, without lens. Note the kapton tape which needs to be removed!" ],

|

|

|

327

|

+])

|

|

|

328

|

+%-->

|

|

|

329

|

+

|

|

|

330

|

+Now all billard balls work fine, regardless of their colour.

|

|

|

331

|

+Even the white ball works without any problems.

|

|

|

332

|

+With the electronics and the firmware ready, we could now move on to refining the mechanics.

|

|

|

333

|

+

|

|

|

334

|

+## First Prototype

|

|

|

335

|

+<a class="anchor" name="first_prototype"></a>

|

|

|

336

|

+

|

|

|

337

|

+The first top case was printed on Philipps [Anycubic Photon Mono 4K](https://www.anycubic.com/products/photon-mono-4k) SLA printer with [Anycubic Standard Resin + Grey](https://amzn.to/3RSLslf).

|

|

|

338

|

+This turned out to not be the best choice.

|

|

|

339

|

+The resin is very brittle after curing, so after pressing the switches in for the first time, and pulling on them, small parts of the print immediately broke off.

|

|

|

340

|

+So I had to super-glue the switches in place.

|

|

|

341

|

+

|

|

|

342

|

+<!--%

|

|

|

343

|

+lightgallery([

|

|

|

344

|

+ [ "img/trackball_v1_6.jpg", "Top of first case print" ],

|

|

|

345

|

+ [ "img/trackball_v1_7.jpg", "Sensor mounted inside first case print" ],

|

|

|

346

|

+ [ "img/trackball_v1_5.jpg", "Side of first case print" ],

|

|

|

347

|

+])

|

|

|

348

|

+%-->

|

|

|

349

|

+

|

|

|

350

|

+Also because it's not a thermo plastic, the heat melt inserts can not be placed in the usual way.

|

|

|

351

|

+We also used super glue for these, which worked great.

|

|

|

352

|

+

|

|

|

353

|

+<!--%

|

|

|

354

|

+lightgallery([

|

|

|

355

|

+ [ "img/trackball_v1_8.jpg", "Philipp soldering the switches" ],

|

|

|

356

|

+ [ "img/trackball_v1_9.jpg", "Front of completed first version" ],

|

|

|

357

|

+ [ "img/trackball_v1_10.jpg", "Back side of completed first version" ],

|

|

|

358

|

+])

|

|

|

359

|

+%-->

|

|

|

360

|

+

|

|

|

361

|

+The PETG printed bottom case was very slippery on a hard table surface.

|

|

|

362

|

+So I cut a piece of self-adhesive spongy rubber to the proper size and put it on the bottom.

|

|

|

363

|

+This increases friction by a fair amount, but is not yet optimal.

|

|

|

364

|

+I will have to try out some other materials.

|

|

|

365

|

+

|

|

|

366

|

+<!--%

|

|

|

367

|

+lightgallery([

|

|

|

368

|

+ [ "img/trackball_v1_13.jpg", "Before adding spongy rubber on the bottom" ],

|

|

|

369

|

+ [ "img/trackball_v1_14.jpg", "After adding spongy rubber on the bottom" ],

|

|

|

370

|

+])

|

|

|

371

|

+%-->

|

|

|

372

|

+

|

|

|

373

|

+And there we go, a finished and working trackball.

|

|

|

374

|

+

|

|

|

375

|

+<!--%

|

|

|

376

|

+lightgallery([

|

|

|

377

|

+ [ "img/trackball_v1_15.jpg", "Looking into sensor of first version" ],

|

|

|

378

|

+ [ "img/trackball_v1_11.jpg", "First completed Trackball" ],

|

|

|

379

|

+])

|

|

|

380

|

+%-->

|

|

|

381

|

+

|

|

|

382

|

+## Improvements

|

|

|

383

|

+<a class="anchor" name="improvements"></a>

|

|

|

384

|

+

|

|

|

385

|

+For the second iteration we didn't do that many changes in the 3D design.

|

|

|

386

|

+The button orientation has been overhauled.

|

|

|

387

|

+This time we sat down and actually tried to find good positions using measurements on our hands.

|

|

|

388

|

+Also the Pi Pico is no longer mounted in the bottom shell, therefore removing the need of long cables to be able to disassemble the device.

|

|

|

389

|

+

|

|

|

390

|

+This time I printed the top case on my recently acquired [Sparkmaker](sparkmaker_repair.html) SLA printer, with [Anycubic ABS-like Resin black](https://amzn.to/3Xphpmu).

|

|

|

391

|

+

|

|

|

392

|

+<!--%

|

|

|

393

|

+lightgallery([

|

|

|

394

|

+ [ "img/trackball_v1_19.jpg", "Printing the second case" ],

|

|

|

395

|

+ [ "img/trackball_v1_22.jpg", "Sensor mounted in case" ],

|

|

|

396

|

+])

|

|

|

397

|

+%-->

|

|

|

398

|

+

|

|

|

399

|

+One useful aspect of the PMW3360 lens assembly are the two mounting posts.

|

|

|

400

|

+They can be heated to firmly keep them in place.

|

|

|

401

|

+

|

|

|

402

|

+> **Recommendation**: The lens can be permanently secured to the chip package by melting the lens’ guide posts over the chip with heat staking process.

|

|

|

403

|

+Please refer to the application note *PMS0122‐LM19‐LSI‐AN* for more details.

|

|

|

404

|

+

|

|

|

405

|

+Instead of the official (confidential 🙄) method I recommend simply heating a screw or other piece of metal for 5 seconds with a lighter, then pressing it lightly on the post.

|

|

|

406

|

+Make sure everything is clean and the kapto tape removed between sensor and lens.

|

|

|

407

|

+You can see the before and after in the pictures below.

|

|

|

408

|

+

|

|

|

409

|

+<!--%

|

|

|

410

|

+lightgallery([

|

|

|

411

|

+ [ "img/trackball_v1_20.jpg", "PMW3360 before melting lens posts" ],

|

|

|

412

|

+ [ "img/trackball_v1_21.jpg", "PMW3360 after melting lens posts" ],

|

|

|

413

|

+])

|

|

|

414

|

+%-->

|

|

|

415

|

+

|

|

|

416

|

+Apart from that nothing much has changed.

|

|

|

417

|

+The heat melt inserts are still super-glued in place.

|

|

|

418

|

+

|

|

|

419

|

+<!--%

|

|

|

420

|

+lightgallery([

|

|

|

421

|

+ [ "img/trackball_v1_28.jpg", "Left side of second version" ],

|

|

|

422

|

+ [ "img/trackball_v1_33.jpg", "Inside view of second version" ],

|

|

|

423

|

+ [ "img/trackball_v1_26.jpg", "Back right of second version" ],

|

|

|

424

|

+])

|

|

|

425

|

+%-->

|

|

|

426

|

+

|

|

|

427

|

+And I used the same rubber mat for the underside.

|

|

|

428

|

+It works good enough that I didn't yet bother with a replacement.

|

|

|

429

|

+

|

|

|

430

|

+<!--%

|

|

|

431

|

+lightgallery([

|

|

|

432

|

+ [ "img/trackball_v1_24.jpg", "Looking into sensor of second version" ],

|

|

|

433

|

+ [ "img/trackball_v1_23.jpg", "Underside of second version" ],

|

|

|

434

|

+])

|

|

|

435

|

+%-->

|

|

|

436

|

+

|

|

|

437

|

+## User Experience

|

|

|

438

|

+<a class="anchor" name="user_experience"></a>

|

|

|

439

|

+

|

|

|

440

|

+I have been using these Trackballs for about six weeks at the time of this writing.

|

|

|

441

|

+From a software and electronics perspective they work absolutely fine.

|

|

|

442

|

+No disconnects, jumping cursor or any strange behaviour was observable.

|

|

|

443

|

+So I'm very happy with that.

|

|

|

444

|

+

|

|

|

445

|

+Ufortunately using them is also quite literally painful.

|

|

|

446

|

+They don't score high in terms of ergonomics, at all.

|

|

|

447

|

+The second version, with some more thought put into the placement and orientation of the switches, is an improvement, but there's still a long way to go.

|

|

|

448

|

+

|

|

|

449

|

+But using a device each day that I've built completely myself, from the grounds up in pretty much all aspects, brings me a lot of joy.

|

|

|

450

|

+I highly recommend it.

|

|

|

451

|

+

|

|

|

452

|

+## License

|

|

|

453

|

+<a class="anchor" name="license"></a>

|

|

|

454

|

+

|

|

|

455

|

+The Trackball is licensed under the [GNU General Public License](https://www.gnu.org/licenses/gpl-3.0.en.html).

|

|

|

456

|

+

|

|

|

457

|

+ This program is free software: you can redistribute it and/or modify

|

|

|

458

|

+ it under the terms of the GNU General Public License as published by

|

|

|

459

|

+ the Free Software Foundation, either version 3 of the License, or

|

|

|

460

|

+ (at your option) any later version.

|

|

|

461

|

+

|

|

|

462

|

+ This program is distributed in the hope that it will be useful,

|

|

|

463

|

+ but WITHOUT ANY WARRANTY; without even the implied warranty of

|

|

|

464

|

+ MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the

|

|

|

465

|

+ GNU General Public License for more details.

|

|

|

466

|

+

|

|

|

467

|

+ See <http://www.gnu.org/licenses/>.

|

|

|

468

|

+

|

|

|

469

|

+## More Pictures

|

|

|

470

|

+<a class="anchor" name="more_pictures"></a>

|

|

|

471

|

+

|

|

|

472

|

+<div class="collapse">Some more photographs I didn't use above.</div>

|

|

|

473

|

+<div class="collapsecontent">

|

|

|

474

|

+<!--%

|

|

|

475

|

+lightgallery([

|

|

|

476

|

+ [ "img/trackball_v1_25.jpg", "Back right of second version" ],

|

|

|

477

|

+ [ "img/trackball_v1_18.jpg", "Printing the second case, badly lit" ],

|

|

|

478

|

+ [ "img/trackball_v1_29.jpg", "Second version, badly lit" ],

|

|

|

479

|

+ [ "img/trackball_v1_30.jpg", "Second version, badly lit" ],

|

|

|

480

|

+ [ "img/trackball_v1_31.jpg", "Second version, badly lit" ],

|

|

|

481

|

+ [ "img/trackball_v1_32.jpg", "Second version, badly lit" ],

|

|

|

482

|

+])

|

|

|

483

|

+%-->

|

|

|

484

|

+</div>

|