Pārlūkot izejas kodu

add sparkmaker shelf

11 mainītis faili ar 59 papildinājumiem un 0 dzēšanām

+ 59

- 0

input/projects/3d-printing/sparkmaker_repair.md

Parādīt failu

|

||

| 4 | 4 |

|

| 5 | 5 |

|

| 6 | 6 |

|

| 7 |

|

|

| 7 | 8 |

|

| 8 | 9 |

|

| 9 | 10 |

|

|

||

| 17 | 18 |

|

| 18 | 19 |

|

| 19 | 20 |

|

| 21 |

|

|

| 20 | 22 |

|

| 21 | 23 |

|

| 22 | 24 |

|

|

||

| 27 | 29 |

|

| 28 | 30 |

|

| 29 | 31 |

|

| 32 |

|

|

| 30 | 33 |

|

| 31 | 34 |

|

| 32 | 35 |

|

|

||

| 257 | 260 |

|

| 258 | 261 |

|

| 259 | 262 |

|

| 263 |

|

|

| 264 |

|

|

| 265 |

|

|

| 266 |

|

|

| 267 |

|

|

| 268 |

|

|

| 269 |

|

|

| 270 |

|

|

| 271 |

|

|

| 272 |

|

|

| 273 |

|

|

| 274 |

|

|

| 275 |

|

|

| 276 |

|

|

| 277 |

|

|

| 278 |

|

|

| 279 |

|

|

| 280 |

|

|

| 281 |

|

|

| 282 |

|

|

| 283 |

|

|

| 284 |

|

|

| 285 |

|

|

| 286 |

|

|

| 287 |

|

|

| 288 |

|

|

| 289 |

|

|

| 290 |

|

|

| 291 |

|

|

| 292 |

|

|

| 293 |

|

|

| 294 |

|

|

| 295 |

|

|

| 296 |

|

|

| 297 |

|

|

| 298 |

|

|

| 299 |

|

|

| 300 |

|

|

| 301 |

|

|

| 302 |

|

|

| 303 |

|

|

| 304 |

|

|

| 305 |

|

|

| 306 |

|

|

| 307 |

|

|

| 308 |

|

|

| 309 |

|

|

| 310 |

|

|

| 311 |

|

|

| 312 |

|

|

| 313 |

|

|

| 314 |

|

|

| 315 |

|

|

| 316 |

|

|

| 317 |

|

|

| 318 |

|

|

| 260 | 319 |

|

| 261 | 320 |

|

| 262 | 321 |

|

Binārs

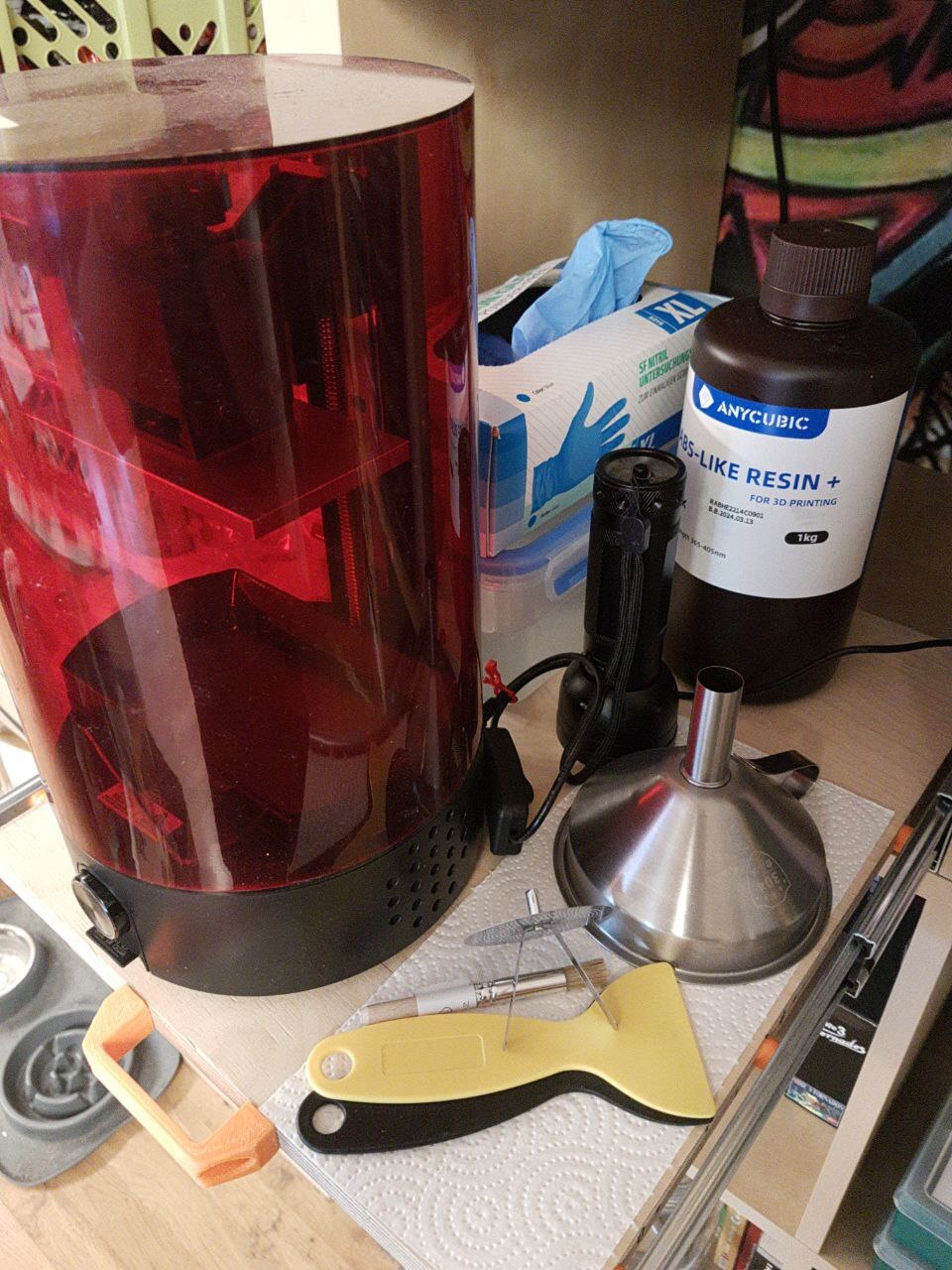

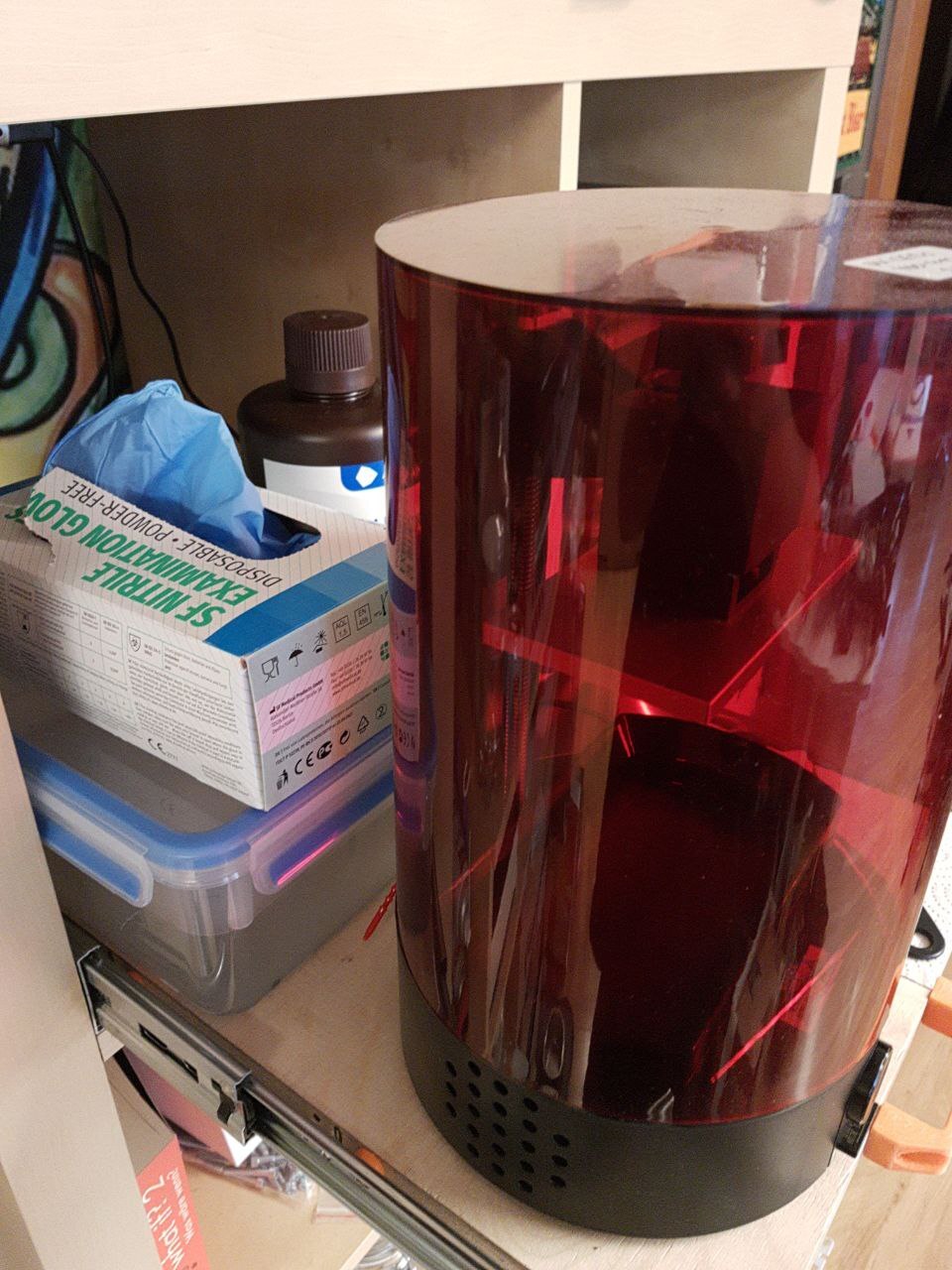

static/img/sparkmaker_shelf_1.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_1_small.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_2.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_2_small.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_3.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_3_small.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_4.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_4_small.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_5.jpg

Parādīt failu

Binārs

static/img/sparkmaker_shelf_5_small.jpg

Parādīt failu

Notiek ielāde…