소스 검색

add wilesco d305 test page

+ 76

- 0

input/blog/2023/2023_09_08_wilesco.md

파일 보기

|

||

| 1 |

|

|

| 2 |

|

|

| 3 |

|

|

| 4 |

|

|

| 5 |

|

|

| 6 |

|

|

| 7 |

|

|

| 8 |

|

|

| 9 |

|

|

| 10 |

|

|

| 11 |

|

|

| 12 |

|

|

| 13 |

|

|

| 14 |

|

|

| 15 |

|

|

| 16 |

|

|

| 17 |

|

|

| 18 |

|

|

| 19 |

|

|

| 20 |

|

|

| 21 |

|

|

| 22 |

|

|

| 23 |

|

|

| 24 |

|

|

| 25 |

|

|

| 26 |

|

|

| 27 |

|

|

| 28 |

|

|

| 29 |

|

|

| 30 |

|

|

| 31 |

|

|

| 32 |

|

|

| 33 |

|

|

| 34 |

|

|

| 35 |

|

|

| 36 |

|

|

| 37 |

|

|

| 38 |

|

|

| 39 |

|

|

| 40 |

|

|

| 41 |

|

|

| 42 |

|

|

| 43 |

|

|

| 44 |

|

|

| 45 |

|

|

| 46 |

|

|

| 47 |

|

|

| 48 |

|

|

| 49 |

|

|

| 50 |

|

|

| 51 |

|

|

| 52 |

|

|

| 53 |

|

|

| 54 |

|

|

| 55 |

|

|

| 56 |

|

|

| 57 |

|

|

| 58 |

|

|

| 59 |

|

|

| 60 |

|

|

| 61 |

|

|

| 62 |

|

|

| 63 |

|

|

| 64 |

|

|

| 65 |

|

|

| 66 |

|

|

| 67 |

|

|

| 68 |

|

|

| 69 |

|

|

| 70 |

|

|

| 71 |

|

|

| 72 |

|

|

| 73 |

|

|

| 74 |

|

|

| 75 |

|

|

| 76 |

|

|

+ 16

- 16

input/projects/dampfmaschine.md

파일 보기

|

||

| 13 | 13 |

|

| 14 | 14 |

|

| 15 | 15 |

|

| 16 |

|

|

| 17 |

|

|

| 18 |

|

|

| 19 |

|

|

| 20 |

|

|

| 21 |

|

|

| 22 |

|

|

| 23 |

|

|

| 24 | 16 |

|

| 25 | 17 |

|

| 26 | 18 |

|

|

||

| 121 | 113 |

|

| 122 | 114 |

|

| 123 | 115 |

|

| 116 |

|

|

| 117 |

|

|

| 118 |

|

|

| 119 |

|

|

| 120 |

|

|

| 121 |

|

|

| 122 |

|

|

| 123 |

|

|

| 124 | 124 |

|

| 125 | 125 |

|

| 126 | 126 |

|

|

||

| 130 | 130 |

|

| 131 | 131 |

|

| 132 | 132 |

|

| 133 |

|

|

| 134 |

|

|

| 135 |

|

|

| 136 |

|

|

| 137 |

|

|

| 138 |

|

|

| 139 |

|

|

| 140 |

|

|

| 141 | 133 |

|

| 142 | 134 |

|

| 143 | 135 |

|

|

||

| 237 | 229 |

|

| 238 | 230 |

|

| 239 | 231 |

|

| 232 |

|

|

| 233 |

|

|

| 234 |

|

|

| 235 |

|

|

| 236 |

|

|

| 237 |

|

|

| 238 |

|

|

| 239 |

|

|

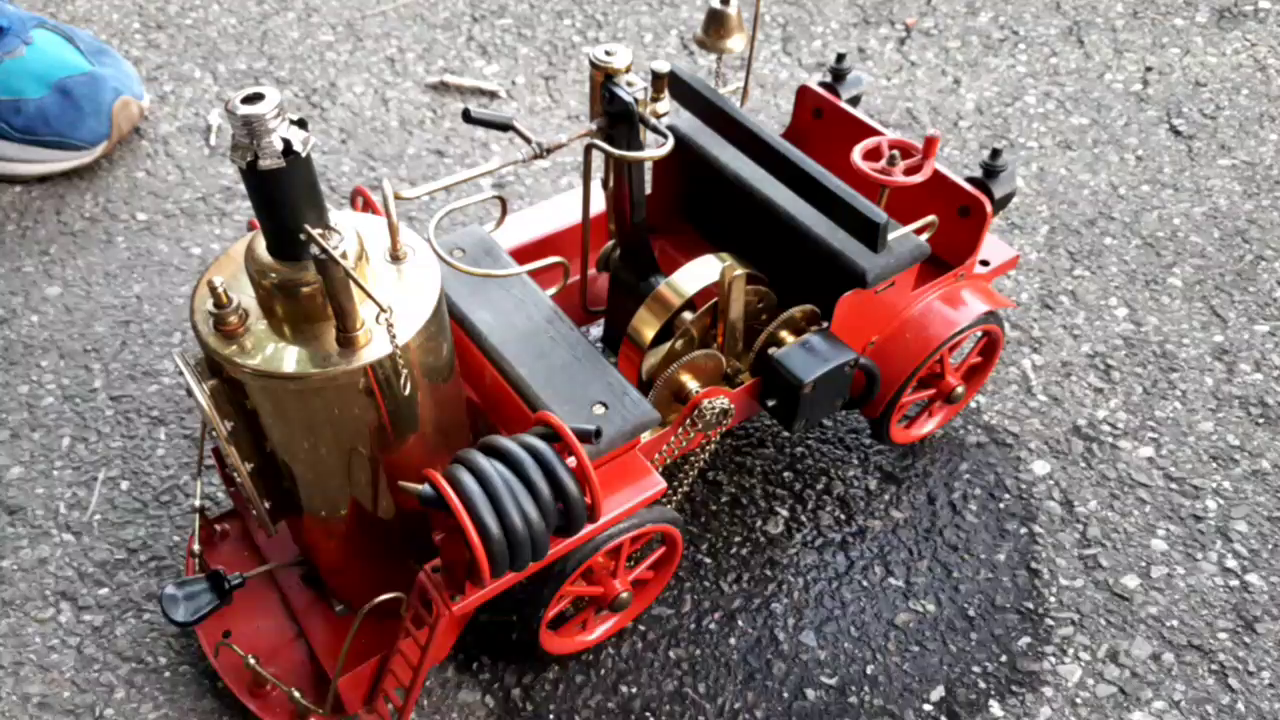

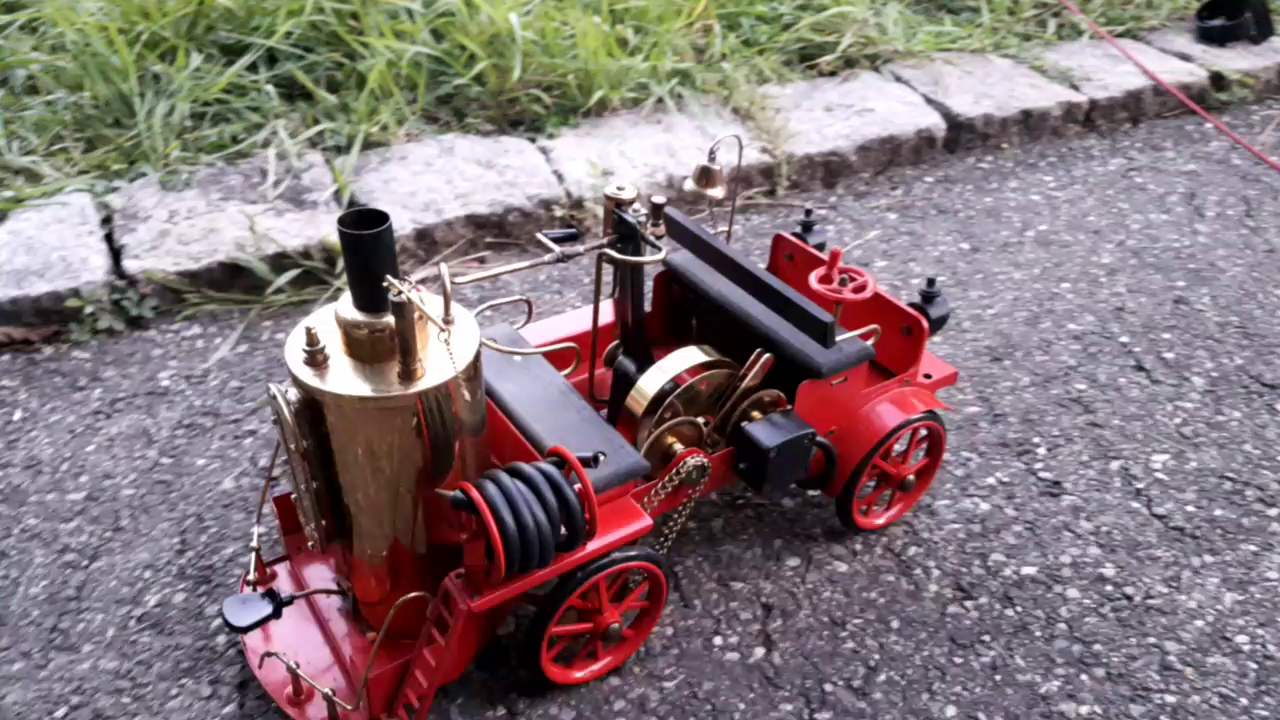

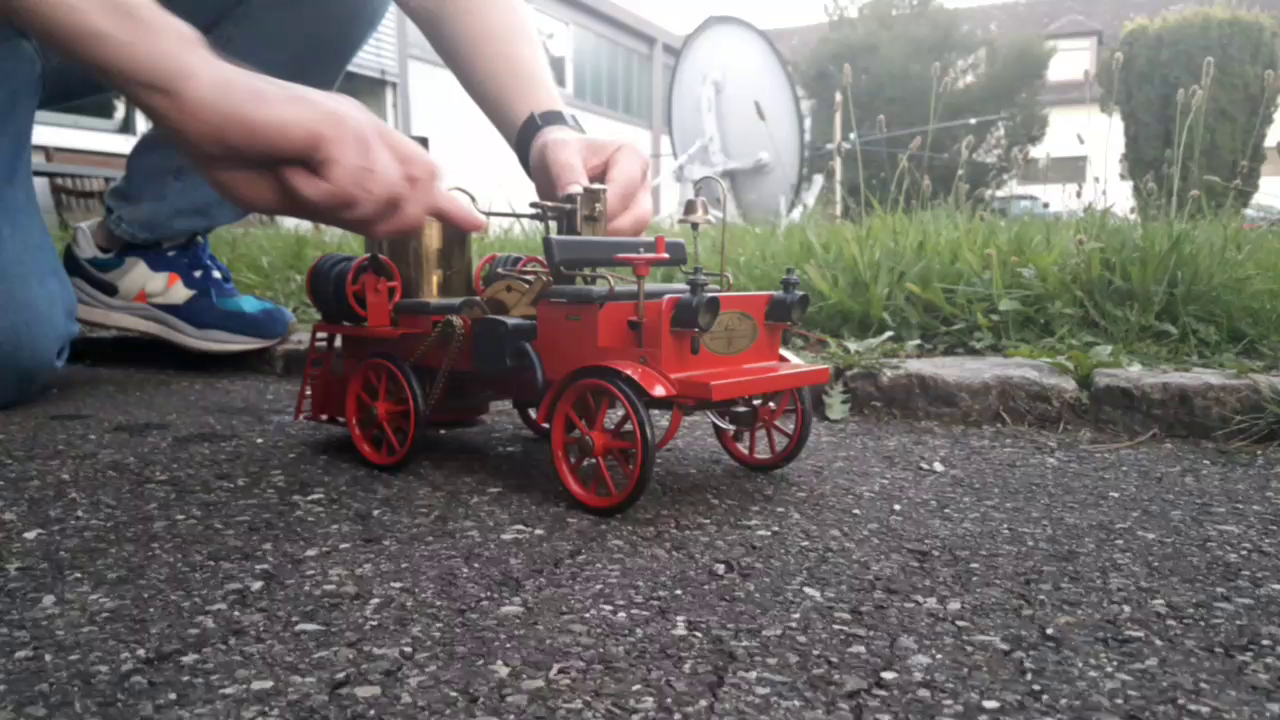

BIN

static/img/wilesco_feuerwehr_1.jpg

파일 보기

BIN

static/img/wilesco_feuerwehr_1_small.jpg

파일 보기

BIN

static/img/wilesco_feuerwehr_2.jpg

파일 보기

BIN

static/img/wilesco_feuerwehr_2_small.jpg

파일 보기

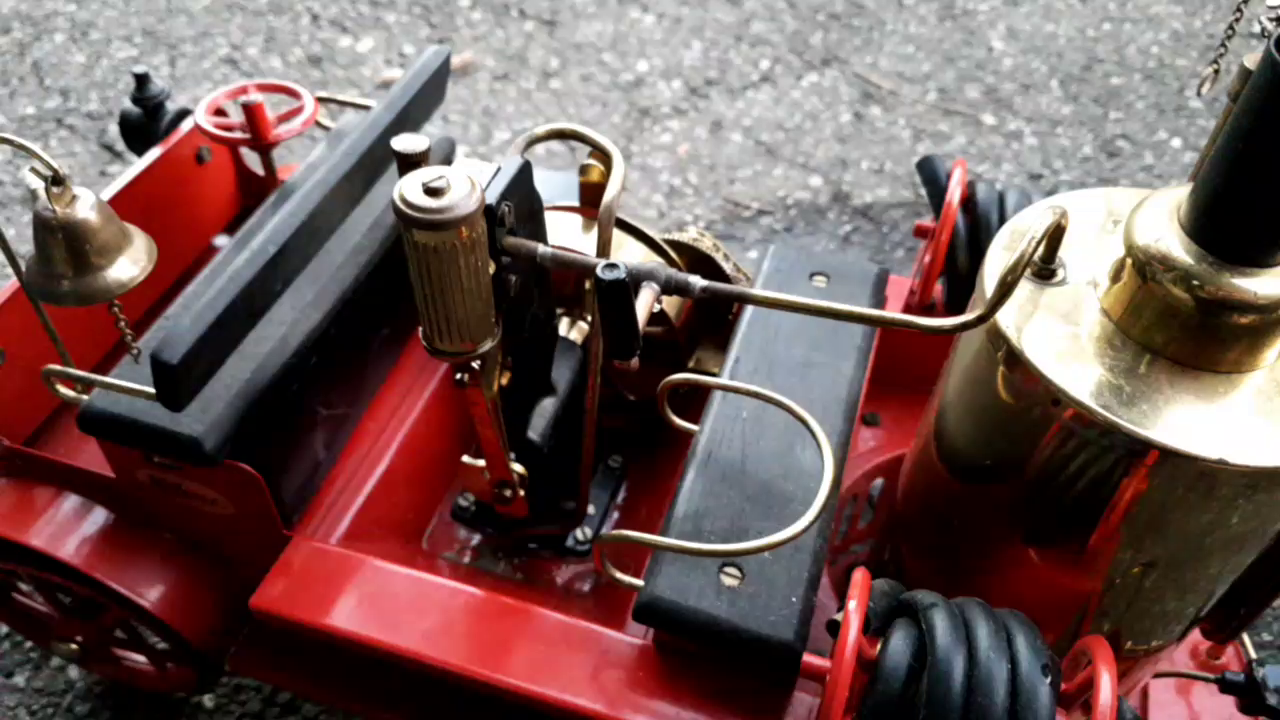

BIN

static/img/wilesco_feuerwehr_3.jpg

파일 보기

BIN

static/img/wilesco_feuerwehr_3_small.jpg

파일 보기

BIN

static/img/wilesco_feuerwehr_v_1.mp4

파일 보기

BIN

static/img/wilesco_feuerwehr_v_1_poster.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_1_thumb.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_2.mp4

파일 보기

BIN

static/img/wilesco_feuerwehr_v_2_poster.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_2_thumb.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_3.mp4

파일 보기

BIN

static/img/wilesco_feuerwehr_v_3_poster.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_3_thumb.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_4.mp4

파일 보기

BIN

static/img/wilesco_feuerwehr_v_4_poster.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_4_thumb.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_5.mp4

파일 보기

BIN

static/img/wilesco_feuerwehr_v_5_poster.png

파일 보기

BIN

static/img/wilesco_feuerwehr_v_5_thumb.png

파일 보기

Loading…