Quellcode durchsuchen

add unfinished hidden am8 page

19 geänderte Dateien mit 122 neuen und 0 gelöschten Zeilen

+ 122

- 0

input/projects/3d-printing/i3-am8.md

Datei anzeigen

|

||

| 1 |

|

|

| 2 |

|

|

| 3 |

|

|

| 4 |

|

|

| 5 |

|

|

| 6 |

|

|

| 7 |

|

|

| 8 |

|

|

| 9 |

|

|

| 10 |

|

|

| 11 |

|

|

| 12 |

|

|

| 13 |

|

|

| 14 |

|

|

| 15 |

|

|

| 16 |

|

|

| 17 |

|

|

| 18 |

|

|

| 19 |

|

|

| 20 |

|

|

| 21 |

|

|

| 22 |

|

|

| 23 |

|

|

| 24 |

|

|

| 25 |

|

|

| 26 |

|

|

| 27 |

|

|

| 28 |

|

|

| 29 |

|

|

| 30 |

|

|

| 31 |

|

|

| 32 |

|

|

| 33 |

|

|

| 34 |

|

|

| 35 |

|

|

| 36 |

|

|

| 37 |

|

|

| 38 |

|

|

| 39 |

|

|

| 40 |

|

|

| 41 |

|

|

| 42 |

|

|

| 43 |

|

|

| 44 |

|

|

| 45 |

|

|

| 46 |

|

|

| 47 |

|

|

| 48 |

|

|

| 49 |

|

|

| 50 |

|

|

| 51 |

|

|

| 52 |

|

|

| 53 |

|

|

| 54 |

|

|

| 55 |

|

|

| 56 |

|

|

| 57 |

|

|

| 58 |

|

|

| 59 |

|

|

| 60 |

|

|

| 61 |

|

|

| 62 |

|

|

| 63 |

|

|

| 64 |

|

|

| 65 |

|

|

| 66 |

|

|

| 67 |

|

|

| 68 |

|

|

| 69 |

|

|

| 70 |

|

|

| 71 |

|

|

| 72 |

|

|

| 73 |

|

|

| 74 |

|

|

| 75 |

|

|

| 76 |

|

|

| 77 |

|

|

| 78 |

|

|

| 79 |

|

|

| 80 |

|

|

| 81 |

|

|

| 82 |

|

|

| 83 |

|

|

| 84 |

|

|

| 85 |

|

|

| 86 |

|

|

| 87 |

|

|

| 88 |

|

|

| 89 |

|

|

| 90 |

|

|

| 91 |

|

|

| 92 |

|

|

| 93 |

|

|

| 94 |

|

|

| 95 |

|

|

| 96 |

|

|

| 97 |

|

|

| 98 |

|

|

| 99 |

|

|

| 100 |

|

|

| 101 |

|

|

| 102 |

|

|

| 103 |

|

|

| 104 |

|

|

| 105 |

|

|

| 106 |

|

|

| 107 |

|

|

| 108 |

|

|

| 109 |

|

|

| 110 |

|

|

| 111 |

|

|

| 112 |

|

|

| 113 |

|

|

| 114 |

|

|

| 115 |

|

|

| 116 |

|

|

| 117 |

|

|

| 118 |

|

|

| 119 |

|

|

| 120 |

|

|

| 121 |

|

|

| 122 |

|

|

BIN

static/img/am8_corexz_1.png

Datei anzeigen

BIN

static/img/am8_corexz_1_small.png

Datei anzeigen

BIN

static/img/am8_corexz_2.png

Datei anzeigen

BIN

static/img/am8_corexz_2_small.png

Datei anzeigen

BIN

static/img/am8_corexz_3.png

Datei anzeigen

BIN

static/img/am8_corexz_3_small.png

Datei anzeigen

BIN

static/img/am8_lcd_assy.jpg

Datei anzeigen

BIN

static/img/am8_lcd_assy_small.jpg

Datei anzeigen

BIN

static/img/am8_lcd_front.jpg

Datei anzeigen

BIN

static/img/am8_lcd_front_small.jpg

Datei anzeigen

BIN

static/img/am8_lcd_post_op.jpg

Datei anzeigen

BIN

static/img/am8_lcd_post_op_small.jpg

Datei anzeigen

BIN

static/img/am8_lcd_pre_op.jpg

Datei anzeigen

BIN

static/img/am8_lcd_pre_op_small.jpg

Datei anzeigen

BIN

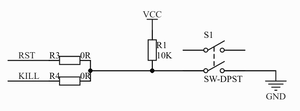

static/img/am8_lcd_rst_kill.png

Datei anzeigen

BIN

static/img/am8_lcd_rst_kill_small.png

Datei anzeigen

BIN

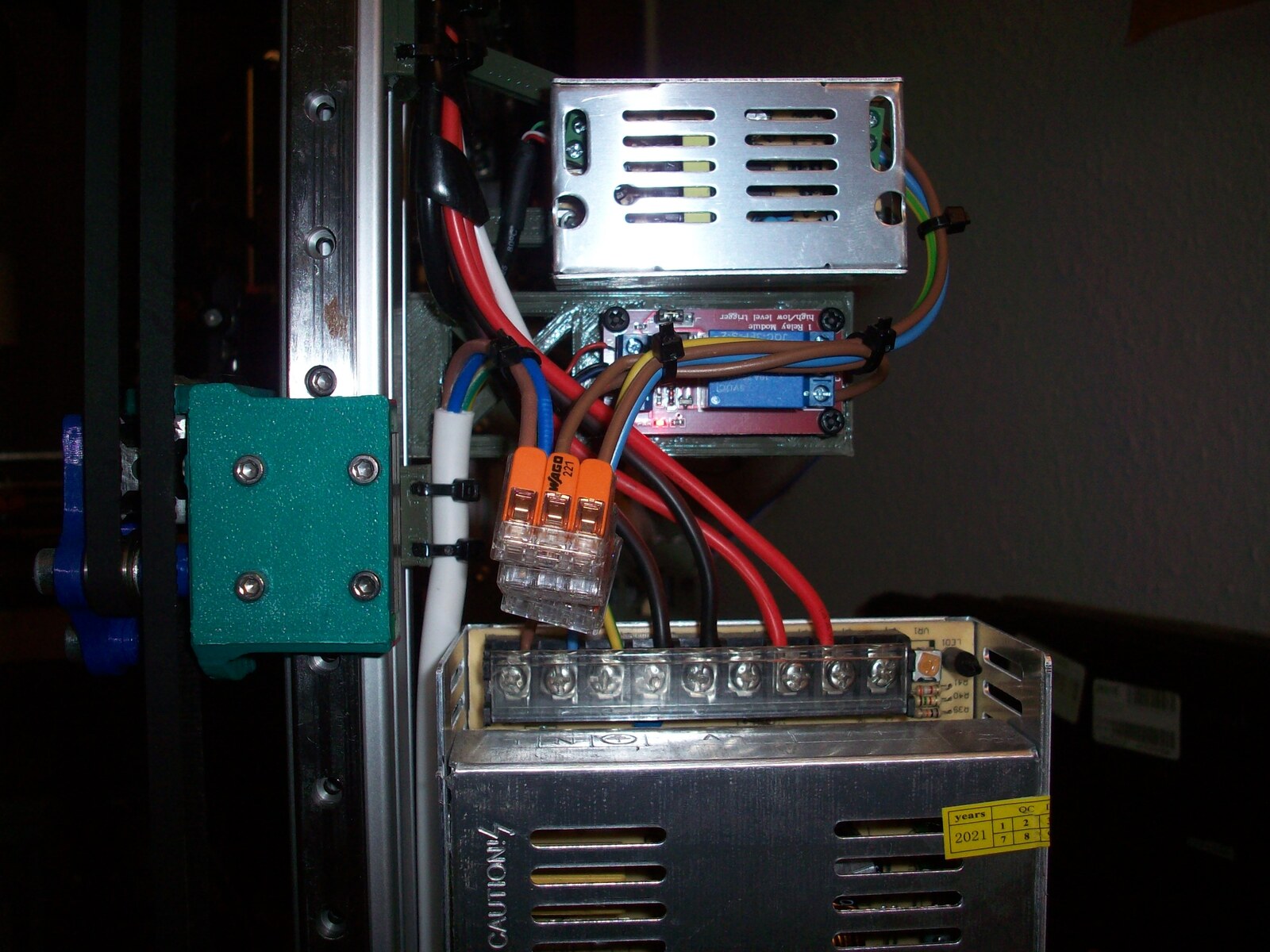

static/img/am8_psu.jpg

Datei anzeigen

BIN

static/img/am8_psu_small.jpg

Datei anzeigen

Laden…