Browse Source

added lots of stuff to 3d printing pages

69 changed files with 271 additions and 20 deletions

+ 214

- 15

input/projects/3d-printing/ctc-i3.md

View File

|

||

| 8 | 8 |

|

| 9 | 9 |

|

| 10 | 10 |

|

| 11 |

|

|

| 12 |

|

|

| 13 |

|

|

| 14 |

|

|

| 15 |

|

|

| 16 |

|

|

| 17 |

|

|

| 18 |

|

|

| 19 |

|

|

| 20 |

|

|

| 21 |

|

|

| 22 |

|

|

| 23 |

|

|

| 24 |

|

|

| 25 |

|

|

| 11 |

|

|

| 12 |

|

|

| 13 |

|

|

| 14 |

|

|

| 15 |

|

|

| 16 |

|

|

| 17 |

|

|

| 18 |

|

|

| 19 |

|

|

| 20 |

|

|

| 21 |

|

|

| 22 |

|

|

| 23 |

|

|

| 24 |

|

|

| 25 |

|

|

| 26 |

|

|

| 27 |

|

|

| 28 |

|

|

| 29 |

|

|

| 30 |

|

|

| 31 |

|

|

| 32 |

|

|

| 33 |

|

|

| 34 |

|

|

| 35 |

|

|

| 36 |

|

|

| 37 |

|

|

| 38 |

|

|

| 39 |

|

|

| 40 |

|

|

| 41 |

|

|

| 42 |

|

|

| 43 |

|

|

| 44 |

|

|

| 45 |

|

|

| 46 |

|

|

| 47 |

|

|

| 48 |

|

|

| 49 |

|

|

| 50 |

|

|

| 51 |

|

|

| 52 |

|

|

| 53 |

|

|

| 54 |

|

|

| 55 |

|

|

| 56 |

|

|

| 57 |

|

|

| 58 |

|

|

| 59 |

|

|

| 60 |

|

|

| 61 |

|

|

| 62 |

|

|

| 63 |

|

|

| 64 |

|

|

| 65 |

|

|

| 66 |

|

|

| 67 |

|

|

| 68 |

|

|

| 69 |

|

|

| 70 |

|

|

| 71 |

|

|

| 72 |

|

|

| 73 |

|

|

| 74 |

|

|

| 75 |

|

|

| 76 |

|

|

| 77 |

|

|

| 78 |

|

|

| 79 |

|

|

| 80 |

|

|

| 81 |

|

|

| 82 |

|

|

| 83 |

|

|

| 84 |

|

|

| 85 |

|

|

| 86 |

|

|

| 87 |

|

|

| 88 |

|

|

| 89 |

|

|

| 90 |

|

|

| 91 |

|

|

| 92 |

|

|

| 93 |

|

|

| 94 |

|

|

| 95 |

|

|

| 96 |

|

|

| 97 |

|

|

| 98 |

|

|

| 99 |

|

|

| 100 |

|

|

| 101 |

|

|

| 102 |

|

|

| 103 |

|

|

| 104 |

|

|

| 105 |

|

|

| 106 |

|

|

| 107 |

|

|

| 108 |

|

|

| 109 |

|

|

| 110 |

|

|

| 111 |

|

|

| 112 |

|

|

| 113 |

|

|

| 114 |

|

|

| 115 |

|

|

| 116 |

|

|

| 117 |

|

|

| 118 |

|

|

| 119 |

|

|

| 120 |

|

|

| 121 |

|

|

| 122 |

|

|

| 123 |

|

|

| 124 |

|

|

| 125 |

|

|

| 126 |

|

|

| 127 |

|

|

| 128 |

|

|

| 129 |

|

|

| 130 |

|

|

| 131 |

|

|

| 132 |

|

|

| 133 |

|

|

| 134 |

|

|

| 135 |

|

|

| 136 |

|

|

| 137 |

|

|

| 138 |

|

|

| 139 |

|

|

| 140 |

|

|

| 141 |

|

|

| 142 |

|

|

| 143 |

|

|

| 144 |

|

|

| 145 |

|

|

| 146 |

|

|

| 147 |

|

|

| 148 |

|

|

| 149 |

|

|

| 150 |

|

|

| 151 |

|

|

| 152 |

|

|

| 153 |

|

|

| 154 |

|

|

| 155 |

|

|

| 156 |

|

|

| 157 |

|

|

| 158 |

|

|

| 159 |

|

|

| 160 |

|

|

| 161 |

|

|

| 162 |

|

|

| 163 |

|

|

| 164 |

|

|

| 165 |

|

|

| 166 |

|

|

| 167 |

|

|

| 168 |

|

|

| 169 |

|

|

| 170 |

|

|

| 171 |

|

|

| 172 |

|

|

| 173 |

|

|

| 174 |

|

|

| 175 |

|

|

| 176 |

|

|

| 177 |

|

|

| 178 |

|

|

| 179 |

|

|

| 180 |

|

|

| 181 |

|

|

| 182 |

|

|

| 183 |

|

|

| 184 |

|

|

| 185 |

|

|

| 186 |

|

|

| 187 |

|

|

| 188 |

|

|

| 189 |

|

|

| 190 |

|

|

| 191 |

|

|

| 192 |

|

|

| 193 |

|

|

| 194 |

|

|

| 195 |

|

|

| 196 |

|

|

| 197 |

|

|

| 198 |

|

|

| 199 |

|

|

| 200 |

|

|

| 201 |

|

|

| 202 |

|

|

| 203 |

|

|

| 204 |

|

|

| 205 |

|

|

| 206 |

|

|

| 207 |

|

|

| 208 |

|

|

| 209 |

|

|

| 210 |

|

|

| 211 |

|

|

| 212 |

|

|

| 213 |

|

|

| 214 |

|

|

| 215 |

|

|

| 216 |

|

|

| 217 |

|

|

| 218 |

|

|

| 219 |

|

|

| 220 |

|

|

| 221 |

|

|

| 222 |

|

|

| 223 |

|

|

| 224 |

|

|

| 26 | 225 |

|

+ 23

- 5

input/projects/3d-printing/fabrikator-mini.md

View File

|

||

| 20 | 20 |

|

| 21 | 21 |

|

| 22 | 22 |

|

| 23 |

|

|

| 23 |

|

|

| 24 |

|

|

| 25 |

|

|

| 26 |

|

|

| 27 |

|

|

| 28 |

|

|

| 24 | 29 |

|

| 25 | 30 |

|

| 26 | 31 |

|

|

||

| 140 | 145 |

|

| 141 | 146 |

|

| 142 | 147 |

|

| 143 |

|

|

| 148 |

|

|

| 149 |

|

|

| 150 |

|

|

| 151 |

|

|

| 152 |

|

|

| 144 | 153 |

|

| 145 | 154 |

|

| 146 | 155 |

|

|

||

| 175 | 184 |

|

| 176 | 185 |

|

| 177 | 186 |

|

| 178 |

|

|

| 187 |

|

|

| 188 |

|

|

| 189 |

|

|

| 190 |

|

|

| 191 |

|

|

| 179 | 192 |

|

| 180 | 193 |

|

| 181 | 194 |

|

|

||

| 185 | 198 |

|

| 186 | 199 |

|

| 187 | 200 |

|

| 188 |

|

|

| 201 |

|

|

| 202 |

|

|

| 203 |

|

|

| 204 |

|

|

| 205 |

|

|

| 189 | 206 |

|

| 190 | 207 |

|

| 191 | 208 |

|

|

||

| 201 | 218 |

|

| 202 | 219 |

|

| 203 | 220 |

|

| 204 |

|

|

| 221 |

|

|

| 222 |

|

|

| 205 | 223 |

|

| 206 | 224 |

|

| 207 | 225 |

|

+ 34

- 0

input/projects/3d-printing/ikea-lack.md

View File

|

||

| 19 | 19 |

|

| 20 | 20 |

|

| 21 | 21 |

|

| 22 |

|

|

| 23 |

|

|

| 24 |

|

|

| 22 | 25 |

|

| 23 | 26 |

|

| 27 |

|

|

| 28 |

|

|

| 29 |

|

|

| 24 | 30 |

|

| 25 | 31 |

|

| 26 | 32 |

|

|

||

| 31 | 37 |

|

| 32 | 38 |

|

| 33 | 39 |

|

| 40 |

|

|

| 41 |

|

|

| 42 |

|

|

| 43 |

|

|

| 44 |

|

|

| 45 |

|

|

| 46 |

|

|

| 34 | 47 |

|

| 35 | 48 |

|

| 49 |

|

|

| 50 |

|

|

| 51 |

|

|

| 52 |

|

|

| 53 |

|

|

| 54 |

|

|

| 55 |

|

|

| 56 |

|

|

| 57 |

|

|

| 58 |

|

|

| 36 | 59 |

|

| 60 |

|

|

| 61 |

|

|

| 62 |

|

|

| 63 |

|

|

| 64 |

|

|

| 65 |

|

|

| 66 |

|

|

| 37 | 67 |

|

| 38 | 68 |

|

| 39 | 69 |

|

|

||

| 121 | 151 |

|

| 122 | 152 |

|

| 123 | 153 |

|

| 154 |

|

|

| 155 |

|

|

| 156 |

|

|

| 157 |

|

|

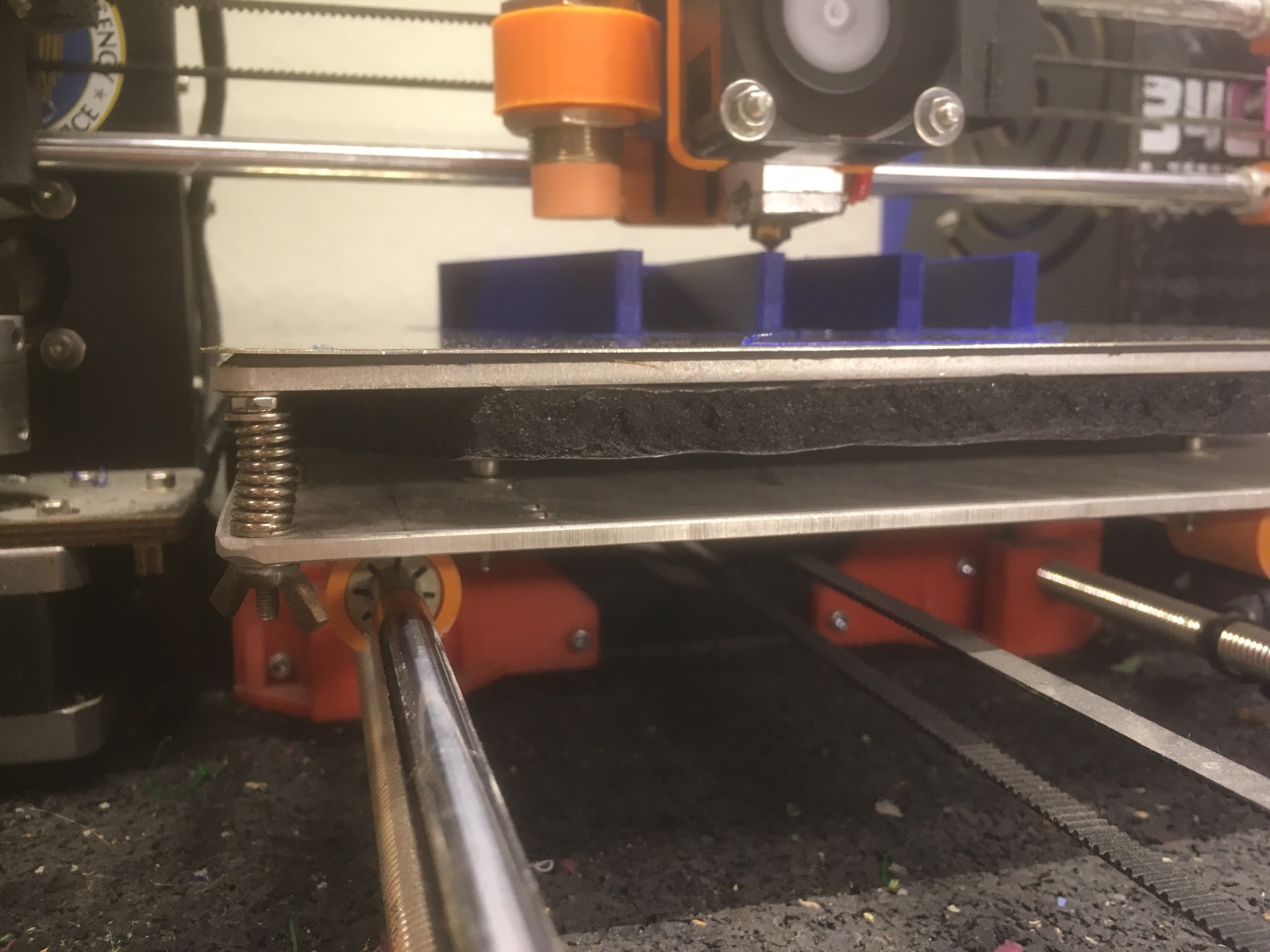

BIN

static/img/ctc_i3_bed.jpg

View File

BIN

static/img/ctc_i3_bed_small.jpg

View File

BIN

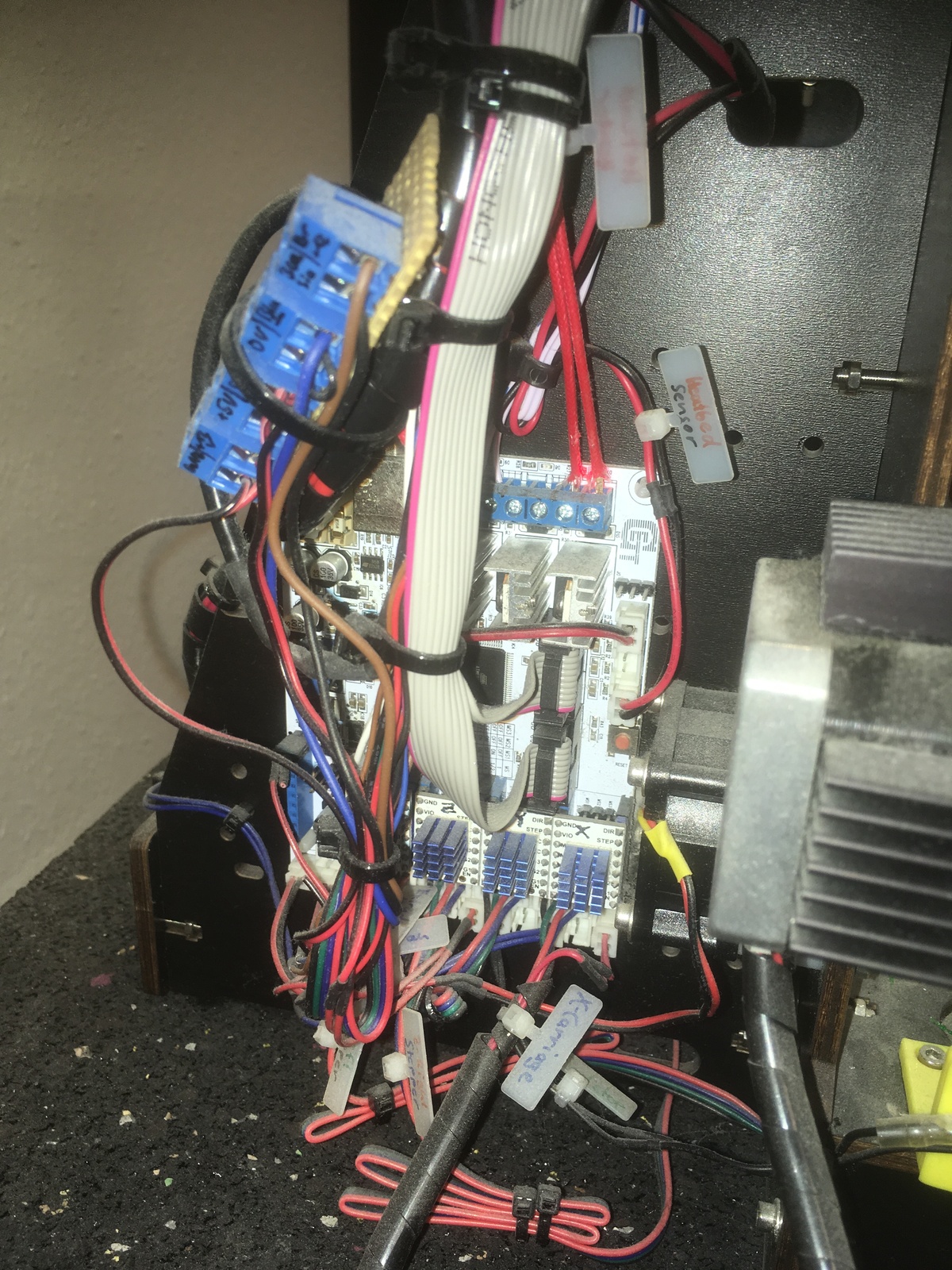

static/img/ctc_i3_board.jpg

View File

BIN

static/img/ctc_i3_board_small.jpg

View File

BIN

static/img/ctc_i3_cam.jpg

View File

BIN

static/img/ctc_i3_cam_small.jpg

View File

BIN

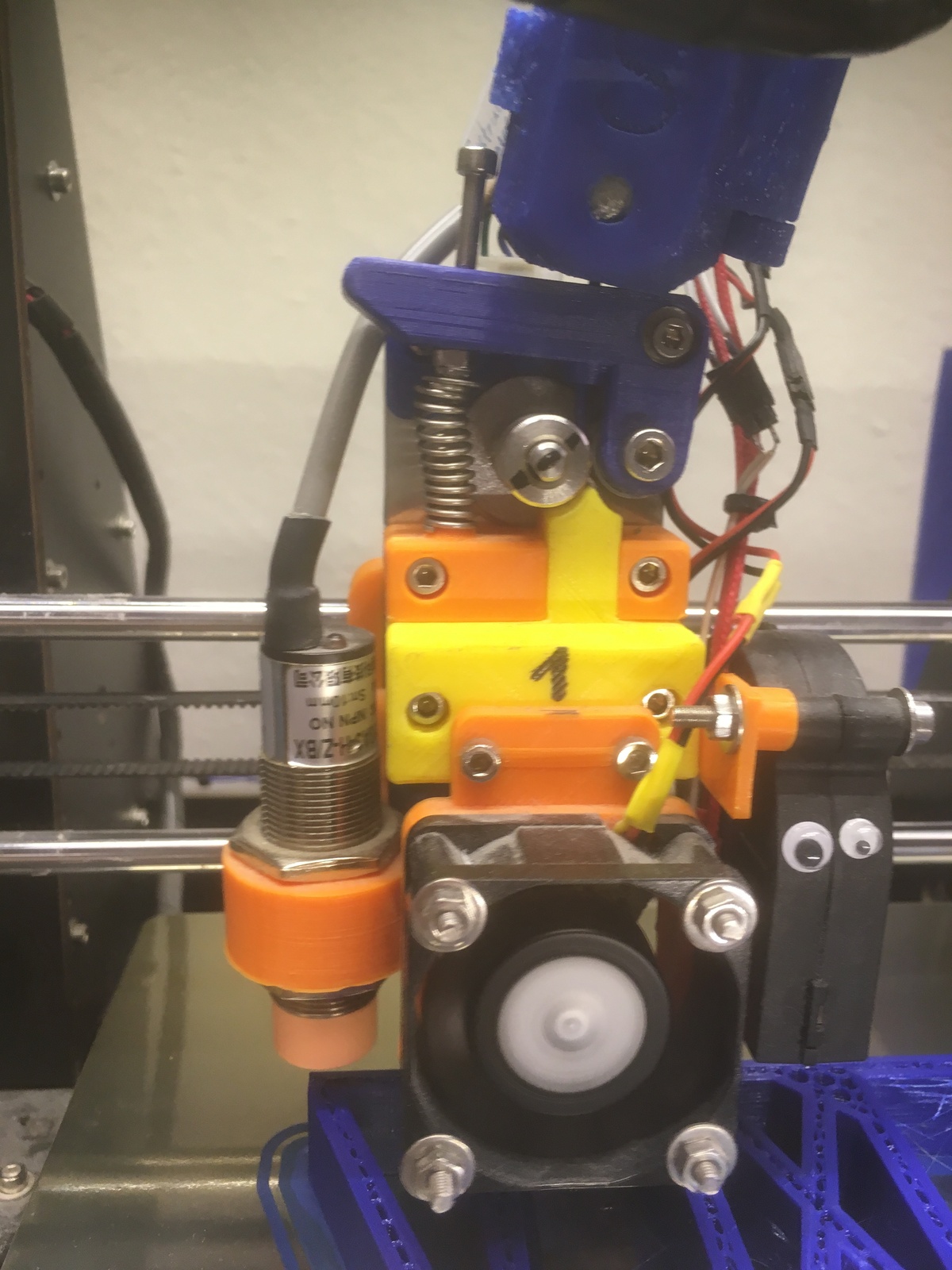

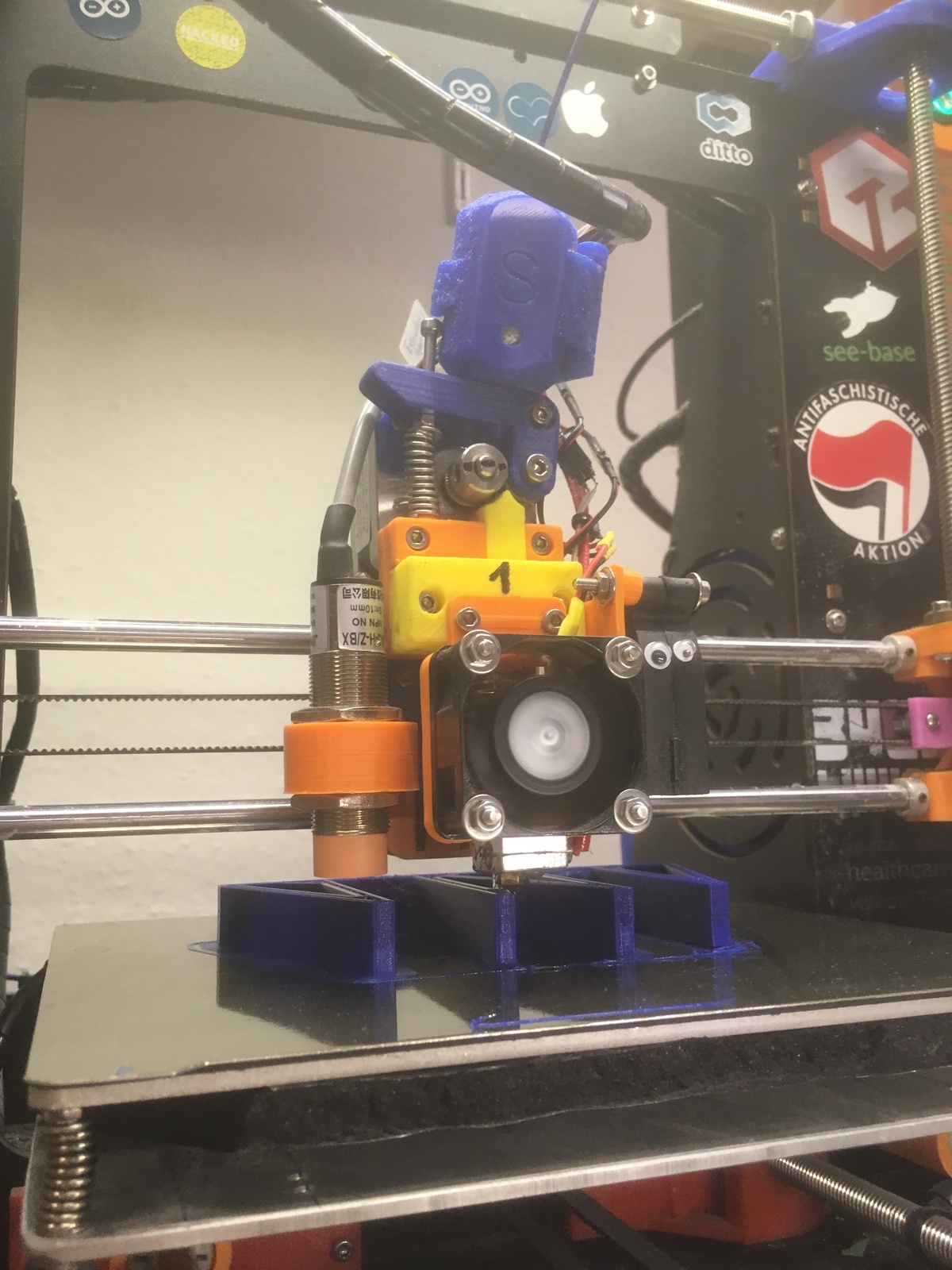

static/img/ctc_i3_extruder.jpg

View File

BIN

static/img/ctc_i3_extruder2.jpg

View File

BIN

static/img/ctc_i3_extruder2_small.jpg

View File

BIN

static/img/ctc_i3_extruder_small.jpg

View File

BIN

static/img/ctc_i3_fet.jpg

View File

BIN

static/img/ctc_i3_fet_small.jpg

View File

BIN

static/img/ctc_i3_front.jpg

View File

BIN

static/img/ctc_i3_front_small.jpg

View File

BIN

static/img/ctc_i3_pi.jpg

View File

BIN

static/img/ctc_i3_pi_small.jpg

View File

BIN

static/img/ctc_i3_power.jpg

View File

BIN

static/img/ctc_i3_power_small.jpg

View File

BIN

static/img/ctc_i3_psu.jpg

View File

BIN

static/img/ctc_i3_psu_small.jpg

View File

BIN

static/img/ctc_i3_side.jpg

View File

BIN

static/img/ctc_i3_side_small.jpg

View File

BIN

static/img/ctc_i3_top_left.jpg

View File

BIN

static/img/ctc_i3_top_left_small.jpg

View File

BIN

static/img/ctc_i3_top_right.jpg

View File

BIN

static/img/ctc_i3_top_right_small.jpg

View File

BIN

static/img/ctc_i3_x_left.jpg

View File

BIN

static/img/ctc_i3_x_left_small.jpg

View File

BIN

static/img/ctc_i3_x_right.jpg

View File

BIN

static/img/ctc_i3_x_right_small.jpg

View File

BIN

static/img/ctc_i3_y_belt.jpg

View File

BIN

static/img/ctc_i3_y_belt_small.jpg

View File

BIN

static/img/ctc_i3_y_corner.jpg

View File

BIN

static/img/ctc_i3_y_corner_small.jpg

View File

BIN

static/img/fabmin_filament_fan.jpg

View File

BIN

static/img/fabmin_filament_fan_small.jpg

View File

BIN

static/img/fabmin_front.jpg

View File

BIN

static/img/fabmin_front_small.jpg

View File

BIN

static/img/fabmin_pi.jpg

View File

BIN

static/img/fabmin_pi_small.jpg

View File

BIN

static/img/fabmin_relais.jpg

View File

BIN

static/img/fabmin_relais_small.jpg

View File

BIN

static/img/fabmin_side.jpg

View File

BIN

static/img/fabmin_side2.jpg

View File

BIN

static/img/fabmin_side2_small.jpg

View File

BIN

static/img/fabmin_side_small.jpg

View File

BIN

static/img/fabmin_webcam.jpg

View File

BIN

static/img/fabmin_webcam_small.jpg

View File

BIN

static/img/i3_hotend_extruder_1.png

View File

BIN

static/img/i3_hotend_extruder_1_small.png

View File

BIN

static/img/i3_hotend_extruder_2.png

View File

BIN

static/img/i3_hotend_extruder_2_small.png

View File

BIN

static/img/lack_corner.jpg

View File

BIN

static/img/lack_corner_small.jpg

View File

BIN

static/img/lack_extension.jpg

View File

BIN

static/img/lack_extension_small.jpg

View File

BIN

static/img/lack_slide_table.jpg

View File

BIN

static/img/lack_slide_table_small.jpg

View File

BIN

static/img/lack_spool_1.jpg

View File

BIN

static/img/lack_spool_1_small.jpg

View File

BIN

static/img/lack_spool_2.jpg

View File

BIN

static/img/lack_spool_2_small.jpg

View File

BIN

static/img/lack_spool_3.jpg

View File

BIN

static/img/lack_spool_3_small.jpg

View File

BIN

static/img/lack_tools.jpg

View File

BIN

static/img/lack_tools_small.jpg

View File

Loading…