|

|

@@ -1,25 +1,46 @@

|

|

1

|

1

|

title: Laser Engraver

|

|

2

|

|

-description: Marlin based CNC laser engraver with 3D printed parts

|

|

3

|

|

-x-parent: projects

|

|

|

2

|

+description: Marlin based CNC laser engraver / cutter with 3D printed parts

|

|

|

3

|

+parent: projects

|

|

4

|

4

|

git: https://git.xythobuz.de/thomas/marlin/src/branch/laser-engraver

|

|

5

|

|

-x-date: 2022-11-11

|

|

|

5

|

+date: 2022-11-25

|

|

6

|

6

|

comments: true

|

|

7

|

7

|

---

|

|

8

|

8

|

|

|

9

|

9

|

After dabbling in 3D printing for a couple of years now, I had to level-up my Makers toolkit.

|

|

10

|

10

|

The next logical step, in my opinion, is laser engraving / laser cutting.

|

|

11

|

|

-I have to admit, I was initially a bit scared, and still have some respect for the potential hazards posed by the strong and focussed laser beam.

|

|

12

|

|

-So I decided to go slow and start with a low powered diode laser.

|

|

|

11

|

+I have to admit I was initially a bit scared and still have some respect for the potential hazards posed by the strong, focussed laser beam.

|

|

|

12

|

+So I decided to go slow and start with a low powered 2.5W diode laser.

|

|

13

|

13

|

|

|

14

|

14

|

⚠️ Be sure to always use proper laser safety goggles when working with such machines! ⚠️

|

|

15

|

15

|

|

|

16

|

16

|

<!--%

|

|

17

|

17

|

lightgallery([

|

|

18

|

18

|

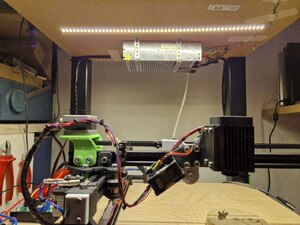

[ "img/laser_tower_1.jpg", "Frontal view in Ikea Lack tower" ],

|

|

|

19

|

+ [ "img/laser_tree_test.mp4", "video/mp4", "", "", "Cutting a christmas tree decoration" ],

|

|

|

20

|

+ [ "img/laser_side_1.jpg", "View from left side" ],

|

|

|

21

|

+ [ "img/laser_side_2.jpg", "View from right side" ],

|

|

19

|

22

|

])

|

|

20

|

23

|

%-->

|

|

21

|

24

|

|

|

|

25

|

+### Table Of Contents

|

|

|

26

|

+

|

|

|

27

|

+* [Hardware](laser-engraver.html#hardware)

|

|

|

28

|

+ * [Mechanics](laser-engraver.html#mechanics)

|

|

|

29

|

+ * [Electronics](laser-engraver.html#electronics)

|

|

|

30

|

+* [Software](laser-engraver.html#software)

|

|

|

31

|

+ * [MCU Firmware](laser-engraver.html#mcu_firmware)

|

|

|

32

|

+ * [Host Software](laser-engraver.html#host_software)

|

|

|

33

|

+ * [LaserGRBL](laser-engraver.html#lasergrbl)

|

|

|

34

|

+ * [Inkscape](laser-engraver.html#inkscape)

|

|

|

35

|

+ * [FreeCAD](laser-engraver.html#freecad)

|

|

|

36

|

+ * [Working with G-Code](laser-engraver.html#g_code)

|

|

|

37

|

+* [Cutting Tests](laser-engraver.html#cutting_tests)

|

|

|

38

|

+* [Future Improvements](laser-engraver.html#future_improvements)

|

|

|

39

|

+* [Cutting Parameters](laser-engraver.html#cutting_parameters)

|

|

|

40

|

+* [More Pictures](laser-engraver.html#more_pictures)

|

|

|

41

|

+

|

|

22

|

42

|

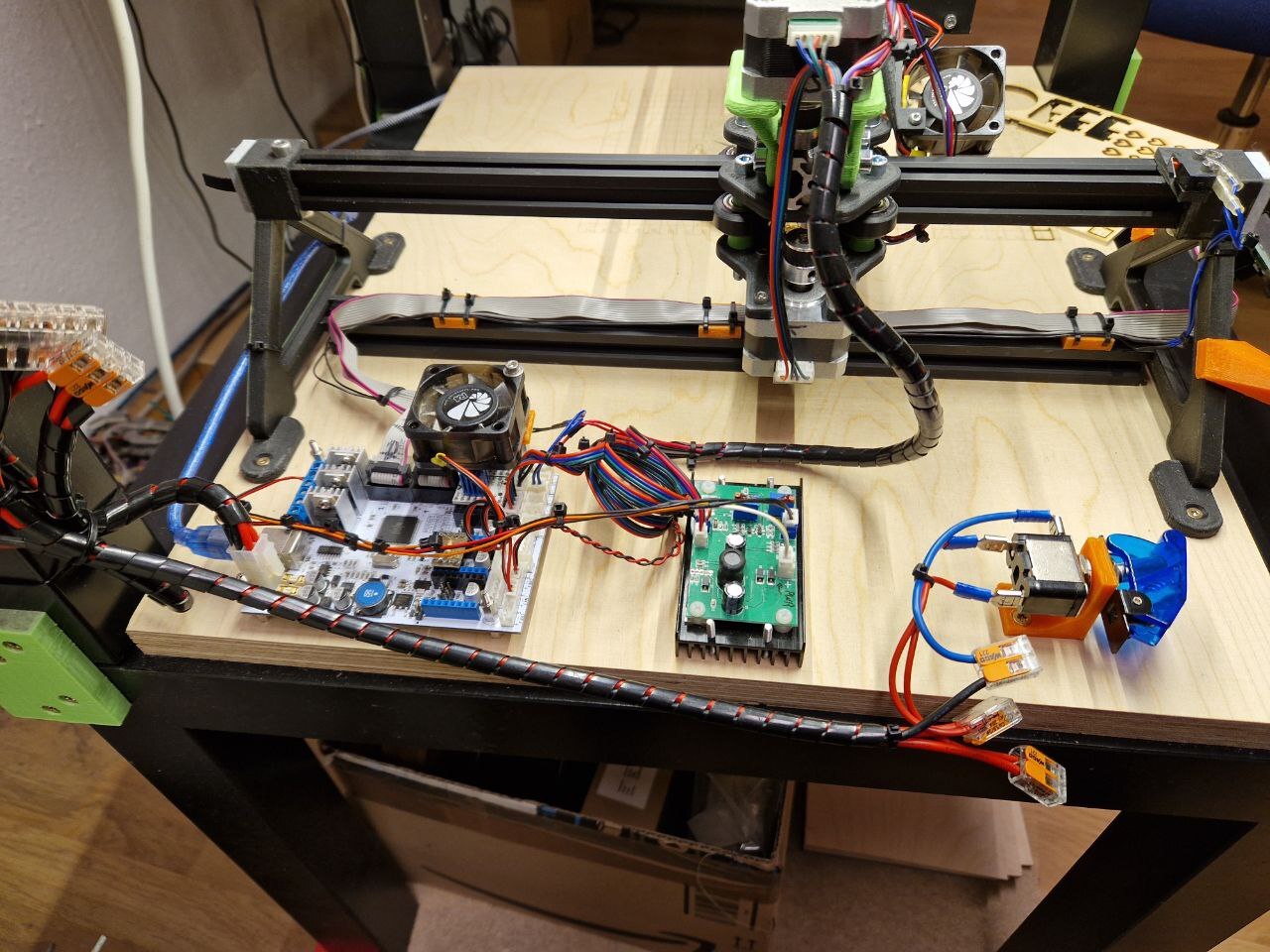

## Hardware

|

|

|

43

|

+<a class="anchor" name="hardware"></a>

|

|

23

|

44

|

|

|

24

|

45

|

I know I say this in a lot of articles here, probably in an attempt to justify my hoarding of electronic parts. 😳

|

|

25

|

46

|

But this was even better than most of my previous projects, in the sense that I didn't have to buy any parts at all, except for the 2500mW 450nm laser diode, which I got used from my colleague [Philipp](https://www.phschoen.de/) for just 13€.

|

|

|

@@ -28,6 +49,7 @@ The steppers, mainboard, display, fans and cables came from my now disassembled

|

|

28

|

49

|

Everything else came out of my parts bin.

|

|

29

|

50

|

|

|

30

|

51

|

### Mechanics

|

|

|

52

|

+<a class="anchor" name="mechanics"></a>

|

|

31

|

53

|

|

|

32

|

54

|

The mechanism is based on the ["Cantilever Laser Engraver" by Meatball](https://www.printables.com/model/213526-cantilever-laser-engraver).

|

|

33

|

55

|

This in turn is based on the ["Cantilever Laser Engraver" by GeoDave](https://www.thingiverse.com/thing:4605853).

|

|

|

@@ -40,6 +62,8 @@ Otherwise the length of the axes can be customized freely.

|

|

40

|

62

|

<!--%

|

|

41

|

63

|

lightgallery([

|

|

42

|

64

|

[ "img/laser_frame.jpg", "Frame of laser engraver, made of 2020 rails" ],

|

|

|

65

|

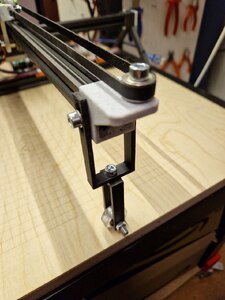

+ [ "img/laser_y_gantry.jpg", "Close view of Y gantry mechanism" ],

|

|

|

66

|

+ [ "img/laser_x_support.jpg", "Close view of X axis support wheel" ],

|

|

43

|

67

|

])

|

|

44

|

68

|

%-->

|

|

45

|

69

|

|

|

|

@@ -56,8 +80,18 @@ I also designed custom endstop mounts using M2.5 heat-melt inserts, as well as a

|

|

56

|

80

|

The OpenSCAD and STL files for these parts [can be found on my Printables profile](https://www.printables.com/model/314945-cantilever-laser-engraver-fixes).

|

|

57

|

81

|

|

|

58

|

82

|

To fit the whole machine comfortably inside my [Ikea Lack tower](ikea-lack.html) I mounted it on a 18mm mutliplex base plate with 540x440mm.

|

|

|

83

|

+The 3D printed feet of the Y-axis already have holes for countersunk screws, so I simply used wood screws there.

|

|

|

84

|

+To mount the mainboard PCB and laser heatsink I made 3.2mm holes for M3 screws and M3 stand-offs, drilling with a 6mm drill from the bottom to approximately half the depth of the base plate, so even cylindrical screw heads don't stand out from below the plate.

|

|

|

85

|

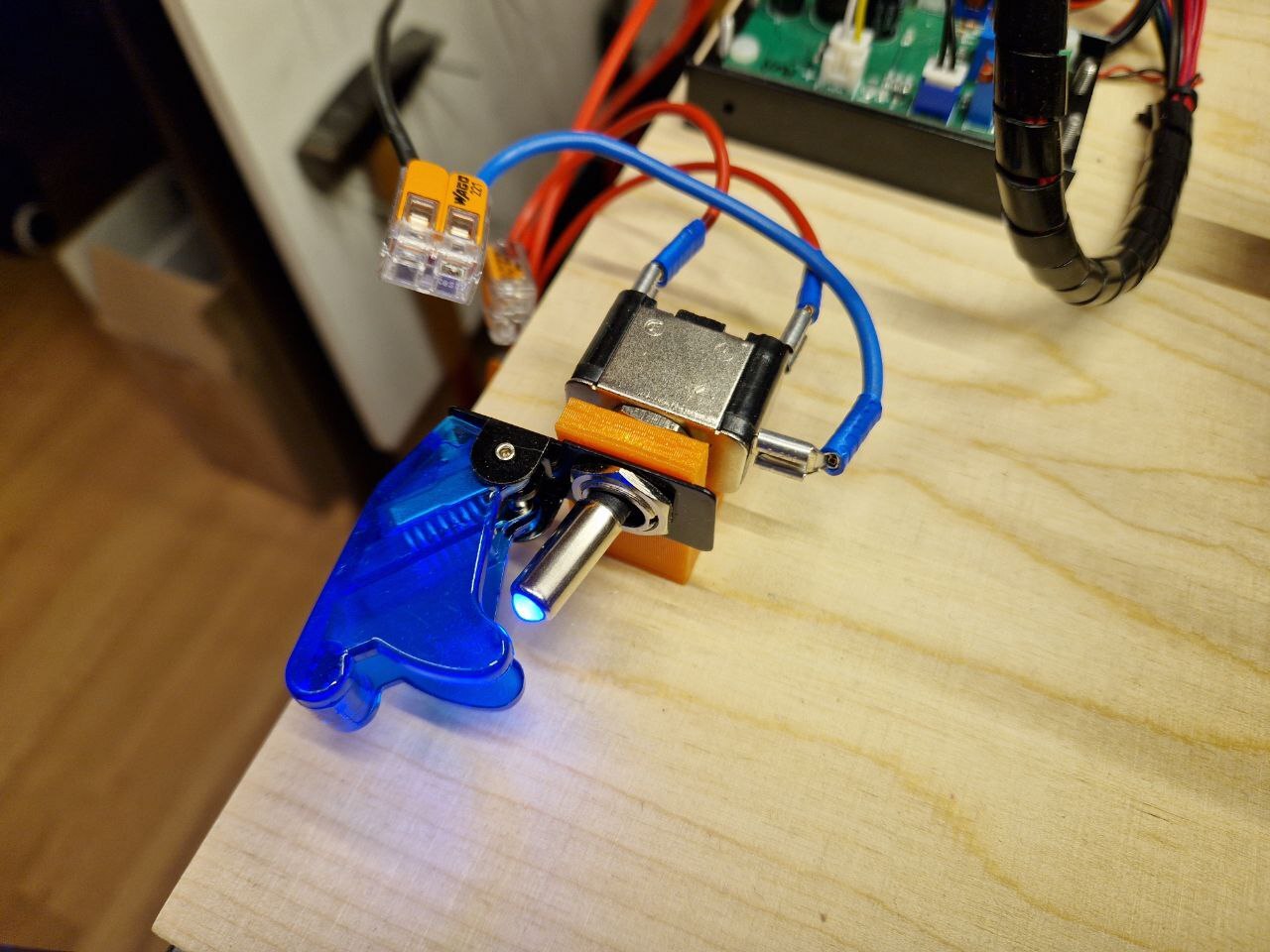

+I also added a power switch with a simple 3D printed mount.

|

|

|

86

|

+

|

|

|

87

|

+<!--%

|

|

|

88

|

+lightgallery([

|

|

|

89

|

+ [ "img/laser_power_switch.jpg", "Power switch with mount" ],

|

|

|

90

|

+])

|

|

|

91

|

+%-->

|

|

59

|

92

|

|

|

60

|

93

|

### Electronics

|

|

|

94

|

+<a class="anchor" name="electronics"></a>

|

|

61

|

95

|

|

|

62

|

96

|

As mentioned above I used the electronics, namely mainboard, LCD and fans, from my old 3D printer.

|

|

63

|

97

|

|

|

|

@@ -95,9 +129,25 @@ And the ground connection is also the one that's switched, when connecting the l

|

|

95

|

129

|

So even when the MOSFET was turned off the laser still had a ground connection and was powered through the ground pin of the TTL connector, so it could never fully turn off.

|

|

96

|

130

|

So if you do the same, make sure to only connect one of the two ground pins!

|

|

97

|

131

|

|

|

|

132

|

+The power supply is simply reused from my [Fabrikator Mini](fabrikator-mini.html), it already was placed in the Ikea Lack tower.

|

|

|

133

|

+To save some space I now mounted it to the top of the next Lack table above the laser, with some strips of perforated metal sheet.

|

|

|

134

|

+Of course this is kind of problematic, as the rest of the machine is kind of designed to be easily transportable.

|

|

|

135

|

+I will have to find some kind of small alternative power supply.

|

|

|

136

|

+

|

|

|

137

|

+<!--%

|

|

|

138

|

+lightgallery([

|

|

|

139

|

+ [ "img/laser_psu.jpg", "12V power supply on underside of Ikea Lack" ],

|

|

|

140

|

+])

|

|

|

141

|

+%-->

|

|

|

142

|

+

|

|

98

|

143

|

## Software

|

|

|

144

|

+<a class="anchor" name="software"></a>

|

|

|

145

|

+

|

|

|

146

|

+There's a surprisingly large amount of software involved in this project.

|

|

|

147

|

+All just to move a lamp around a bit 💡🤔

|

|

99

|

148

|

|

|

100

|

149

|

### MCU Firmware

|

|

|

150

|

+<a class="anchor" name="mcu_firmware"></a>

|

|

101

|

151

|

|

|

102

|

152

|

Most DIY laser engravers or CNC machines seem to use the [GRBL firmware](https://github.com/gnea/grbl).

|

|

103

|

153

|

Unfortunately this firmware only runs on Atmega328p MCUs, so I can not use it with the Atmega2560 on the GT2560 mainboard.

|

|

|

@@ -116,9 +166,14 @@ I also did some small changes to show the current laser power on the LCD status

|

|

116

|

166

|

These changes can be seen [in this commit](https://git.xythobuz.de/thomas/marlin/commit/58dbdff1d5b6e365bfd5ae4eeb7b42967688c51e).

|

|

117

|

167

|

I also opened a [pull request](https://github.com/MarlinFirmware/Marlin/pull/25003) to hopefully upstream them.

|

|

118

|

168

|

|

|

|

169

|

+Later I learned that Marlin does not allow setting home offsets further than 20mm away from endstops.

|

|

|

170

|

+So I also [added a custom menu command](https://git.xythobuz.de/thomas/marlin/commit/74cafcd77625003623d3a8a6378a4ff0ac6eda72) that simply executes [`G92`](https://marlinfw.org/docs/gcode/G092.html) `X0 Y0` to set the current position to zero.

|

|

|

171

|

+Using this I can generate G-Code where the object to cut starts at coordinates `(0, 0)` while being able to position it arbitrarily on the machine itself.

|

|

|

172

|

+

|

|

119

|

173

|

My current Marlin configuration for the laser engraver can be found [on my Gitea instance](https://git.xythobuz.de/thomas/marlin/src/branch/laser-engraver).

|

|

120

|

174

|

|

|

121

|

175

|

### Host Software

|

|

|

176

|

+<a class="anchor" name="host_software"></a>

|

|

122

|

177

|

|

|

123

|

178

|

Besides the microcontroller firmware, we also need some host software to prepare the G-Code from whatever kind of input file we start out with.

|

|

124

|

179

|

There are two basic approaches for generating paths for the laser engraver.

|

|

|

@@ -137,6 +192,7 @@ But it is commercial paid software, not under any free software license, so [it

|

|

137

|

192

|

Below I will try to document all different free software packages I tried for laser engraving.

|

|

138

|

193

|

|

|

139

|

194

|

#### LaserGRBL

|

|

|

195

|

+<a class="anchor" name="lasergrbl"></a>

|

|

140

|

196

|

|

|

141

|

197

|

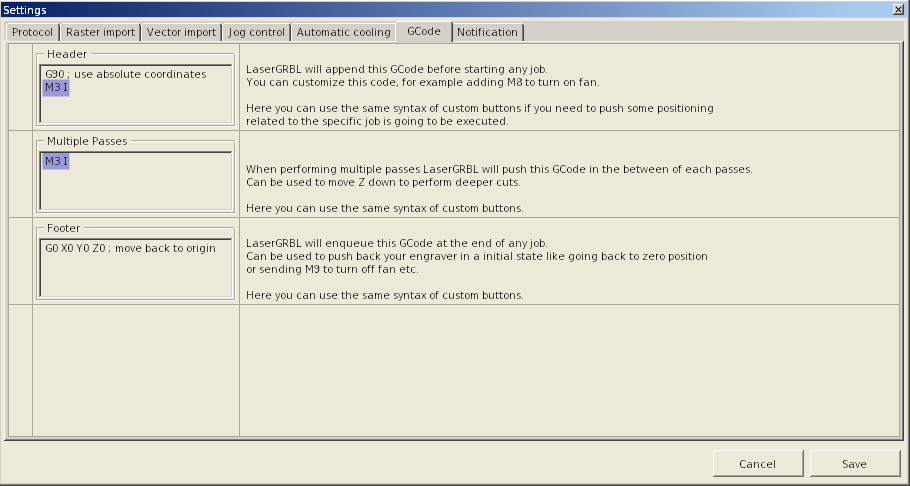

The first solution I found out about is [LaserGRBL](https://lasergrbl.com/).

|

|

142

|

198

|

It is a Windows-only program, but at least it is open-source / free software.

|

|

|

@@ -154,7 +210,7 @@ G1 X23 S150

|

|

154

|

210

|

</pre>

|

|

155

|

211

|

|

|

156

|

212

|

Without further modifications, this only moves the toolhead, while keeping the laser off at all times, because Marlin by default does not process the power-level parts of the G-Code lines.

|

|

157

|

|

-To get this to work, the "continuous inline power mode" has to be enabled by putting `M3 I` in the G-Code header setting of LaserGRBL.

|

|

|

213

|

+To get this to work, the "continuous inline power mode" has to be enabled by putting `M3 I` in the G-Code header setting of LaserGRBL, as well as at the end of the "Multiple Passes" G-Code section.

|

|

158

|

214

|

|

|

159

|

215

|

<!--%

|

|

160

|

216

|

lightgallery([

|

|

|

@@ -197,6 +253,25 @@ For raster input, LaserGRBL only puts the speed in a single G0 move at the begin

|

|

197

|

253

|

So the speed does not apply to the G1 moves afterwards.

|

|

198

|

254

|

This case is not handled yet.

|

|

199

|

255

|

|

|

|

256

|

+In another vector job, I saw LaserGRBL generate output like the following.

|

|

|

257

|

+

|

|

|

258

|

+<pre class="sh_gcode">

|

|

|

259

|

+G0X3Y2

|

|

|

260

|

+S255

|

|

|

261

|

+G1Y5F200

|

|

|

262

|

+X0.7

|

|

|

263

|

+Y8.347

|

|

|

264

|

+X8.25

|

|

|

265

|

+X8.75Y8.847

|

|

|

266

|

+Y12.347

|

|

|

267

|

+</pre>

|

|

|

268

|

+

|

|

|

269

|

+This is the very compact GRBL G-Code dialect, which leaves out spaces and also the modes, as long as they don't change.

|

|

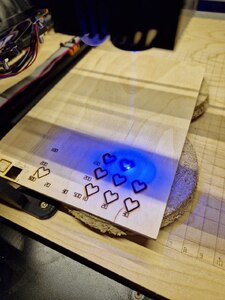

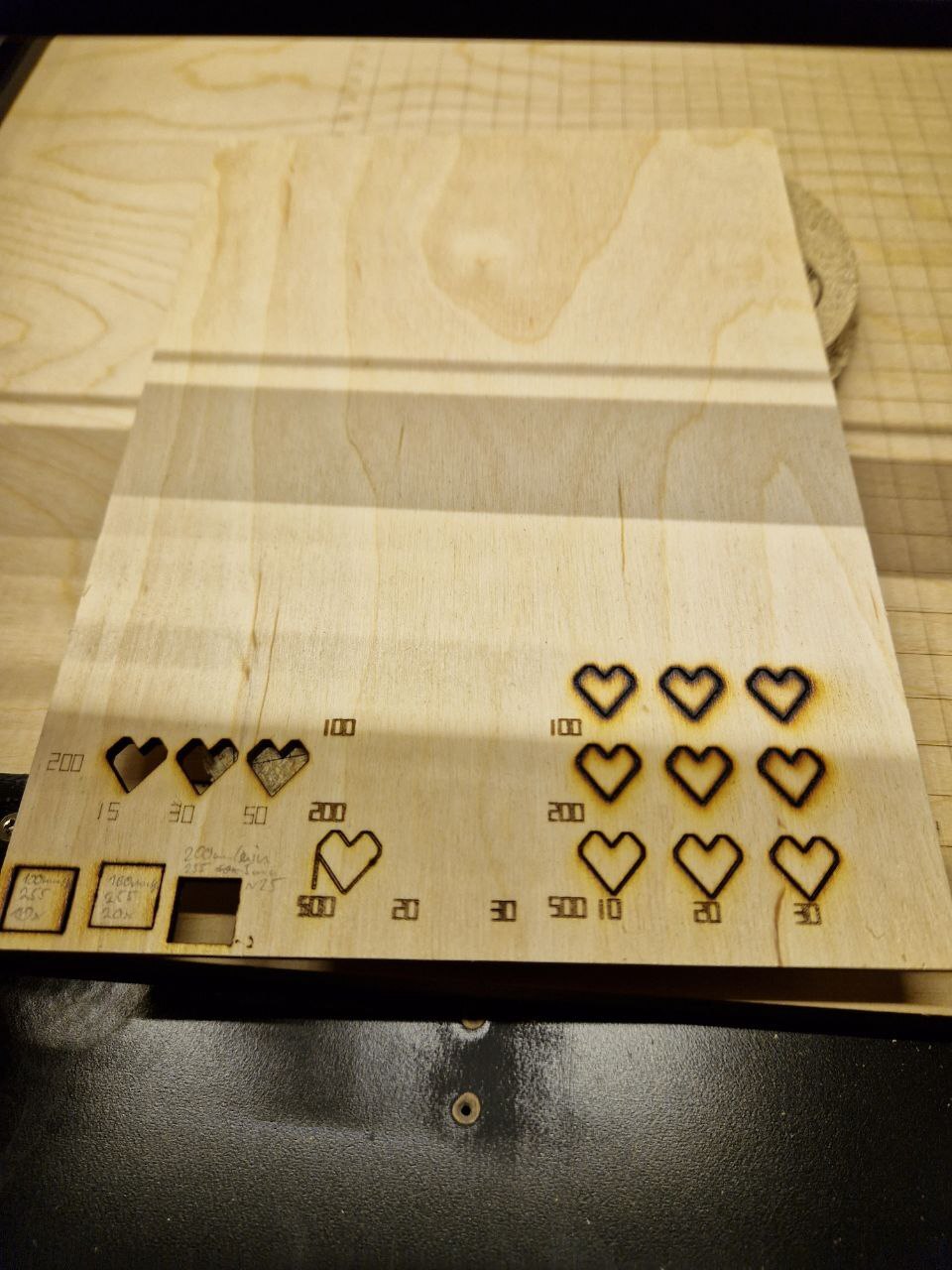

|

270

|

+So to handle that, I remember the last G0/G1 mode, prepending it as needed to lines, while also adding the missing spaces for better human readable output.

|

|

|

271

|

+

|

|

|

272

|

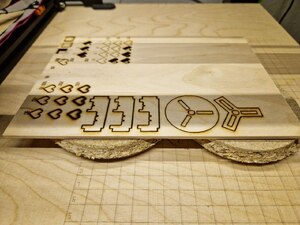

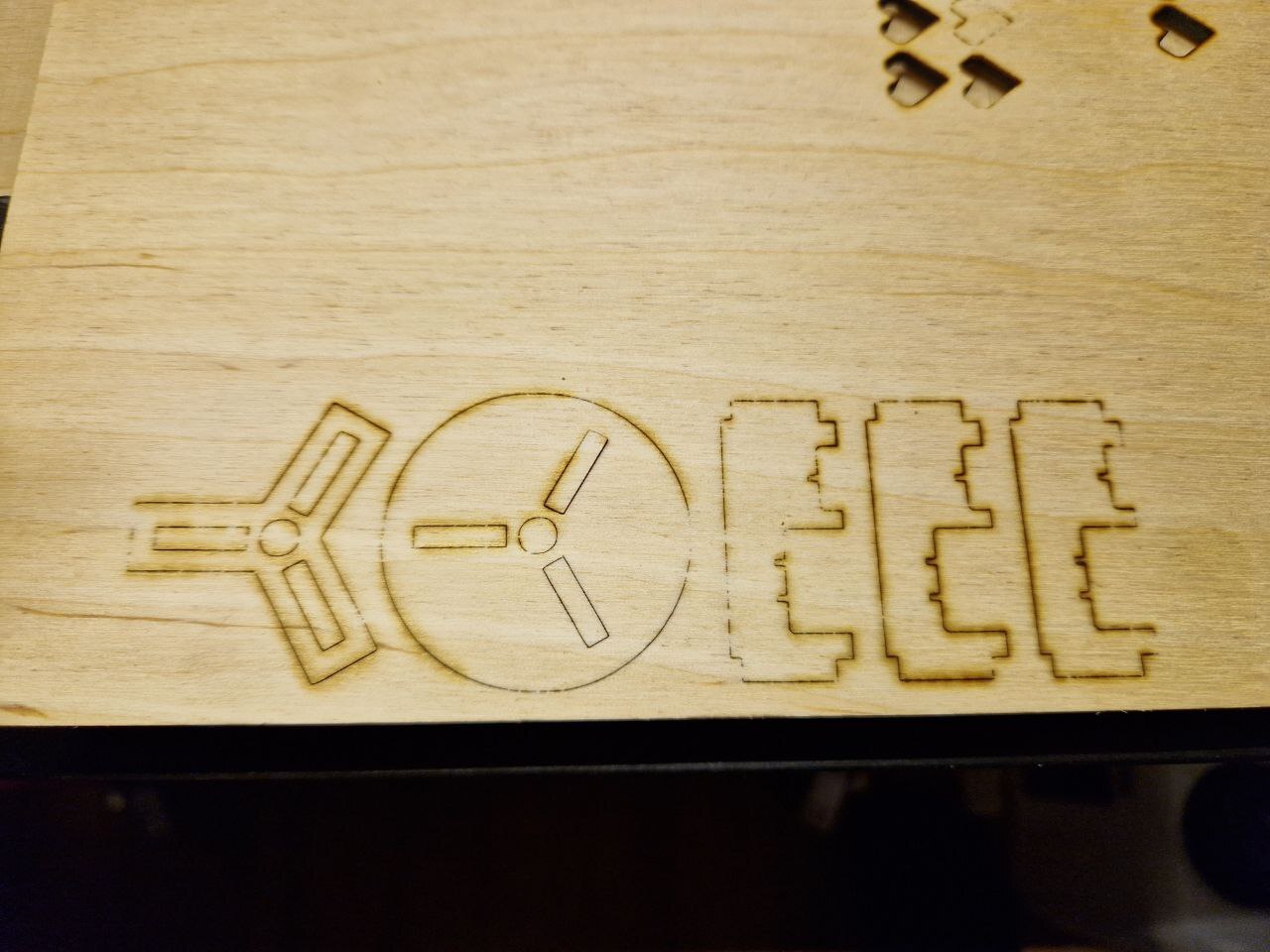

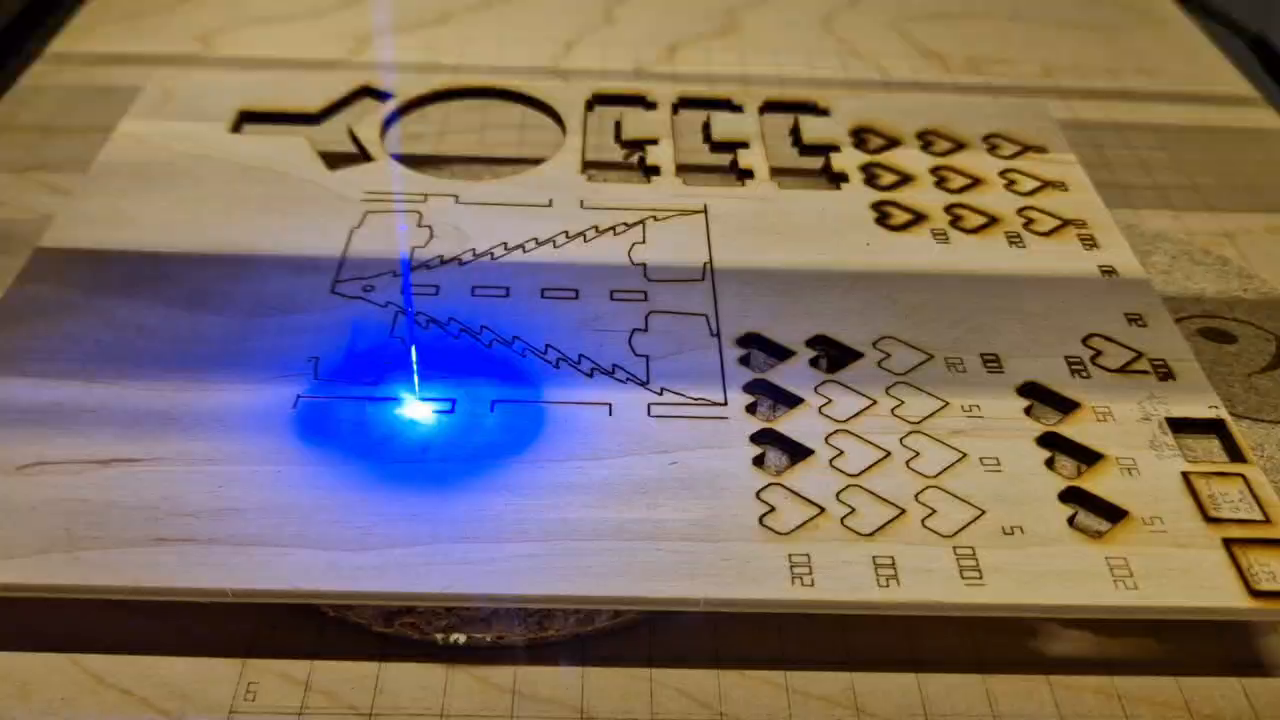

+As you can tell there are many different output formats from LaserGRBL and I'm not able to tell when it will generate what.

|

|

|

273

|

+But my script below should work for all variants I have seen up to now.

|

|

|

274

|

+

|

|

200

|

275

|

<pre class="sh_python">

|

|

201

|

276

|

#!/usr/bin/env python

|

|

202

|

277

|

|

|

|

@@ -212,6 +287,17 @@ out_file = sys.argv[2]

|

|

212

|

287

|

|

|

213

|

288

|

power = ""

|

|

214

|

289

|

speed = ""

|

|

|

290

|

+mode_g0 = True

|

|

|

291

|

+

|

|

|

292

|

+def add_spaces(s):

|

|

|

293

|

+ prev = ' '

|

|

|

294

|

+ r = ""

|

|

|

295

|

+ for c in s:

|

|

|

296

|

+ if str(prev).isdigit() and str(c).isalpha():

|

|

|

297

|

+ r = r + " "

|

|

|

298

|

+ r = r + c

|

|

|

299

|

+ prev = c

|

|

|

300

|

+ return r

|

|

215

|

301

|

|

|

216

|

302

|

with open(in_file, 'r') as fi, open(out_file, 'w') as fo:

|

|

217

|

303

|

for line in fi:

|

|

|

@@ -220,14 +306,26 @@ with open(in_file, 'r') as fi, open(out_file, 'w') as fo:

|

|

220

|

306

|

elif line.startswith("F"):

|

|

221

|

307

|

speed = " " + line.rstrip()

|

|

222

|

308

|

else:

|

|

223

|

|

- s = line.rstrip()

|

|

|

309

|

+ s = add_spaces(line.rstrip())

|

|

224

|

310

|

if line.startswith("G1"):

|

|

|

311

|

+ mode_g0 = False

|

|

225

|

312

|

s += power

|

|

226

|

313

|

s += speed

|

|

227

|

314

|

elif line.startswith("G0"):

|

|

|

315

|

+ mode_g0 = True

|

|

228

|

316

|

s += power

|

|

229

|

317

|

if (power != " S0") and (power != ""):

|

|

230

|

318

|

print("Warning: G0 move with power not zero!" + power)

|

|

|

319

|

+ elif line.startswith("X") or line.startswith("Y"):

|

|

|

320

|

+ if mode_g0:

|

|

|

321

|

+ s = "G0 " + s

|

|

|

322

|

+ s += power

|

|

|

323

|

+ if (power != " S0") and (power != ""):

|

|

|

324

|

+ print("Warning: G0 move with power not zero!" + power)

|

|

|

325

|

+ else:

|

|

|

326

|

+ s = "G1 " + s

|

|

|

327

|

+ s += power

|

|

|

328

|

+ s += speed

|

|

231

|

329

|

s += "\n"

|

|

232

|

330

|

fo.write(s)

|

|

233

|

331

|

</pre>

|

|

|

@@ -245,37 +343,41 @@ For these tests I have simply used LaserGRBL to produce a G-Code file, which I h

|

|

245

|

343

|

LaserGRBL also can directly connect to the machine via the serial port.

|

|

246

|

344

|

This has worked for me for a bit, but even though you can set the G-Code flavor to Marlin in the LaserGRBL settings, it does not really work properly.

|

|

247

|

345

|

You can jog the toolhead but homing is not possible.

|

|

248

|

|

-I also had to reduce the polling frequency in the LaserGRBL settings to 'Quiet' and disable Soft-Reset to get it to work inside the VirtualBox VM I use to run the program.

|

|

|

346

|

+I also had to reduce the polling frequency in the LaserGRBL settings to 'Quiet' and disable Soft-Reset to get it to work inside the VirtualBox VM I used at first to run the program.

|

|

249

|

347

|

|

|

250

|

|

-Apparently it is also possible to [run LaserGRBL in Wine](https://github.com/arkypita/LaserGRBL/issues/5#issuecomment-873564055) / [with PlayOnLinux](https://github.com/arkypita/LaserGRBL/raw/master/POL_LaserGRBL_setup.sh), but on my Arch system I was not able to get either of these running, due to problems with the required Winetricks.

|

|

|

348

|

+It is also possible to [run LaserGRBL in Wine](https://github.com/arkypita/LaserGRBL/issues/5#issuecomment-873564055) / [with PlayOnLinux](https://github.com/arkypita/LaserGRBL/raw/master/POL_LaserGRBL_setup.sh).

|

|

|

349

|

+At first I was not able to run this PlayOnLinux script due to Winetricks downloads failing with invalid checksums.

|

|

|

350

|

+But after trying a couple of days later, with the exact same script, the installation worked fine.

|

|

|

351

|

+I had to make the same changes to the settings as described for VirtualBox above.

|

|

251

|

352

|

|

|

252

|

|

-Also, for all the above tests with LaserGRBL I have imported raster bitmap images and either rastered them, or vectorized them within LaserGRBLs UI.

|

|

|

353

|

+Also for all the above tests with LaserGRBL I have imported raster bitmap images and either rastered them, or vectorized them within LaserGRBLs UI.

|

|

253

|

354

|

With bitmaps it is possible to position the resulting G-Code paths with an offset from the zero position of the machine.

|

|

254

|

355

|

This is not possible when using LaserGRBL to import SVG vector paths.

|

|

255

|

356

|

With them, the output will always start at coordinates `(0, 0)`.

|

|

256

|

|

-You will then have to set the proper offset on the machine itself.

|

|

|

357

|

+You will then have to set the proper offset on the machine itself, as described in the Marlin section above.

|

|

257

|

358

|

|

|

258

|

359

|

#### Inkscape

|

|

|

360

|

+<a class="anchor" name="inkscape"></a>

|

|

259

|

361

|

|

|

260

|

362

|

Inkscape includes the [G-Code Tools Plugin from the russian-language CNC-Club forums](https://www.cnc-club.ru/forum/viewtopic.php?t=35).

|

|

261

|

363

|

Unfortunately I was not able to find much up-to-date english-language documentation for this.

|

|

262

|

364

|

It is also relatively complicated and unintuitive.

|

|

263

|

365

|

|

|

264

|

|

-TODO

|

|

265

|

|

-

|

|

266

|

366

|

I was able to get it to generate G-Code from a path, but not with any laser power instructions yet.

|

|

|

367

|

+This section will be updated if I have more success in the future.

|

|

|

368

|

+Until then I'm just using Inkscape to export svg files for LaserGRBL.

|

|

267

|

369

|

|

|

268

|

370

|

#### FreeCAD

|

|

|

371

|

+<a class="anchor" name="freecad"></a>

|

|

269

|

372

|

|

|

270

|

373

|

FreeCAD has the [Path Workbench](https://wiki.freecadweb.org/Path_Workbench), which can be used to create G-Code instructions for all kinds of CNC machines.

|

|

271

|

374

|

It is not really complete and fool-proof yet, unfortunately.

|

|

272

|

375

|

And it is also not designed for pure 2D machines, like laser engravers, by default.

|

|

273

|

376

|

|

|

274

|

|

-TODO

|

|

275

|

|

-

|

|

276

|

377

|

I have not yet tested that.

|

|

277

|

378

|

|

|

278

|

379

|

#### Working with G-Code

|

|

|

380

|

+<a class="anchor" name="g_code"></a>

|

|

279

|

381

|

|

|

280

|

382

|

One nice feature I saw in LaserGRBL, but was not able to use with Marlin, is the ability to draw the outline of the object to be cut, for positioning of the stock material.

|

|

281

|

383

|

So I quickly made up a small Python script that analyzes a G-Code file, taking the coordinates from all G1 cutting moves and generating their bounding box, which is then drawn on the lowest possible power setting multiple times.

|

|

|

@@ -528,13 +630,491 @@ with open(filename, 'w') as f:

|

|

528

|

630

|

write("G0 X0 Y0 F" + str(speed_g0))

|

|

529

|

631

|

</pre>

|

|

530

|

632

|

|

|

|

633

|

+I like the idea but unfortunately it has some problems in practice.

|

|

|

634

|

+When changing the focus level of my laser diode, it's very easy to also change the offset in the X and Y axes.

|

|

|

635

|

+So the grid is not properly aligned for long.

|

|

|

636

|

+But it still looks nice.

|

|

|

637

|

+

|

|

|

638

|

+<!--%

|

|

|

639

|

+lightgallery([

|

|

|

640

|

+ [ "img/laser_grid.jpg", "Closer view of grid on base plate" ],

|

|

|

641

|

+])

|

|

|

642

|

+%-->

|

|

|

643

|

+

|

|

|

644

|

+If you look closely, you can see the first run I did with a power setting of 50 / 255.

|

|

|

645

|

+This was not strong enough, the lines are only faintly visible.

|

|

|

646

|

+So I did another run with 100 / 255 over it.

|

|

|

647

|

+This was enough power for nice visible lines, but the laser offset unfortunately shifted slightly between the runs.

|

|

|

648

|

+

|

|

|

649

|

+As I grew tired of removing, flashing and re-inserting of the SD card, I decided to also write a quick little G-Code sender for the serial port.

|

|

|

650

|

+

|

|

|

651

|

+<pre class="sh_python">

|

|

|

652

|

+#!/usr/bin/env python

|

|

|

653

|

+

|

|

|

654

|

+import sys

|

|

|

655

|

+import serial

|

|

|

656

|

+

|

|

|

657

|

+if len(sys.argv) < 3:

|

|

|

658

|

+ print("Usage:")

|

|

|

659

|

+ print(" " + sys.argv[0] + " /dev/serial/port input.gcode")

|

|

|

660

|

+ sys.exit(1)

|

|

|

661

|

+

|

|

|

662

|

+port_file = sys.argv[1]

|

|

|

663

|

+in_file = sys.argv[2]

|

|

|

664

|

+

|

|

|

665

|

+port = serial.Serial()

|

|

|

666

|

+port.port = port_file

|

|

|

667

|

+port.baudrate = 115200

|

|

|

668

|

+#port.timeout = 0.0

|

|

|

669

|

+

|

|

|

670

|

+max_cmd_buffer = 5

|

|

|

671

|

+counter = 0

|

|

|

672

|

+

|

|

|

673

|

+def connect_serial():

|

|

|

674

|

+ try:

|

|

|

675

|

+ port.open()

|

|

|

676

|

+ if port.is_open:

|

|

|

677

|

+ print("connected to: " + port_file)

|

|

|

678

|

+ else:

|

|

|

679

|

+ print("error connecting to " + port_file)

|

|

|

680

|

+ sys.exit(1)

|

|

|

681

|

+ except serial.serialutil.SerialException:

|

|

|

682

|

+ print("error connecting to " + port_file)

|

|

|

683

|

+ sys.exit(1)

|

|

|

684

|

+

|

|

|

685

|

+def wait_for_text(s):

|

|

|

686

|

+ while True:

|

|

|

687

|

+ response = port.read_until().decode().strip()

|

|

|

688

|

+ print("rx w: " + response)

|

|

|

689

|

+ if response.startswith(s):

|

|

|

690

|

+ break

|

|

|

691

|

+ elif response.startswith("Error"):

|

|

|

692

|

+ print(response)

|

|

|

693

|

+ print("CNC returned error. aborting.")

|

|

|

694

|

+ abort_print(False)

|

|

|

695

|

+ port.close()

|

|

|

696

|

+ sys.exit(1)

|

|

|

697

|

+

|

|

|

698

|

+def abort_print(wait_for_oks = True):

|

|

|

699

|

+ global counter

|

|

|

700

|

+

|

|

|

701

|

+ print("tx: M5")

|

|

|

702

|

+ port.write("M5\n".encode())

|

|

|

703

|

+ counter += 1

|

|

|

704

|

+

|

|

|

705

|

+ print("tx: G0 X0 Y0 F1000")

|

|

|

706

|

+ port.write("G0 X0 Y0 F1000\n".encode())

|

|

|

707

|

+ counter += 1

|

|

|

708

|

+

|

|

|

709

|

+ if wait_for_oks:

|

|

|

710

|

+ while counter > 0:

|

|

|

711

|

+ wait_for_text("ok")

|

|

|

712

|

+ counter -= 1

|

|

|

713

|

+

|

|

|

714

|

+def send_file(f):

|

|

|

715

|

+ global counter

|

|

|

716

|

+

|

|

|

717

|

+ for line in f:

|

|

|

718

|

+ if ";" in line:

|

|

|

719

|

+ line = line.split(";")[0]

|

|

|

720

|

+

|

|

|

721

|

+ line = line.strip()

|

|

|

722

|

+

|

|

|

723

|

+ if len(line) <= 0:

|

|

|

724

|

+ print("skipping empty line")

|

|

|

725

|

+ continue

|

|

|

726

|

+

|

|

|

727

|

+ print("tx: " + line)

|

|

|

728

|

+ tx = line.encode() + b'\n'

|

|

|

729

|

+ port.write(tx)

|

|

|

730

|

+

|

|

|

731

|

+ counter += 1

|

|

|

732

|

+ print("cnt=" + str(counter))

|

|

|

733

|

+

|

|

|

734

|

+ while counter >= max_cmd_buffer:

|

|

|

735

|

+ response = port.read_until().decode().strip()

|

|

|

736

|

+ #print("rx: " + response)

|

|

|

737

|

+ if response.startswith("ok"):

|

|

|

738

|

+ counter -= 1

|

|

|

739

|

+ print("cnt=" + str(counter))

|

|

|

740

|

+ elif response.startswith("Error"):

|

|

|

741

|

+ print(response)

|

|

|

742

|

+ print("CNC returned error. aborting.")

|

|

|

743

|

+ abort_print(False)

|

|

|

744

|

+ port.close()

|

|

|

745

|

+ sys.exit(1)

|

|

|

746

|

+

|

|

|

747

|

+def main():

|

|

|

748

|

+ connect_serial()

|

|

|

749

|

+

|

|

|

750

|

+ print("waiting for CNC to reset")

|

|

|

751

|

+ wait_for_text("start")

|

|

|

752

|

+

|

|

|

753

|

+ print("auto-homing after reset")

|

|

|

754

|

+ print("tx: G28")

|

|

|

755

|

+ port.write("G28\n".encode())

|

|

|

756

|

+ wait_for_text("ok")

|

|

|

757

|

+

|

|

|

758

|

+ try:

|

|

|

759

|

+ with open(in_file, 'r') as f:

|

|

|

760

|

+ send_file(f)

|

|

|

761

|

+

|

|

|

762

|

+ while counter > 0:

|

|

|

763

|

+ wait_for_text("ok")

|

|

|

764

|

+ counter -= 1

|

|

|

765

|

+ except KeyboardInterrupt:

|

|

|

766

|

+ print("user interrupt. aborting.")

|

|

|

767

|

+ abort_print(True)

|

|

|

768

|

+

|

|

|

769

|

+ port.close()

|

|

|

770

|

+

|

|

|

771

|

+if __name__ == '__main__':

|

|

|

772

|

+ main()

|

|

|

773

|

+</pre>

|

|

|

774

|

+

|

|

|

775

|

+Of course it's important to use the proper speed, power and number of iterations for each object to cut.

|

|

|

776

|

+Not enough power or iterations, or too high of a speed, and the object will still be part of the stock material.

|

|

|

777

|

+Too much power or iterations and not only the object will be cut, but also the base plate below.

|

|

|

778

|

+

|

|

|

779

|

+So I first did some tests manually, which is relatively time consuming.

|

|

|

780

|

+I then made another Python script go generate G-Code for a cutting test, varying speed and number of iterations.

|

|

|

781

|

+

|

|

|

782

|

+<pre class="sh_python">

|

|

|

783

|

+#!/usr/bin/env python

|

|

|

784

|

+

|

|

|

785

|

+# general settings

|

|

|

786

|

+filename = "cut_test.gcode"

|

|

|

787

|

+pwr = 255

|

|

|

788

|

+pwr_num = 150

|

|

|

789

|

+speed_g0 = 3000

|

|

|

790

|

+speed_g1_num = 500

|

|

|

791

|

+

|

|

|

792

|

+# settings of single test shape

|

|

|

793

|

+width = 10

|

|

|

794

|

+height = 10

|

|

|

795

|

+dist = 2

|

|

|

796

|

+

|

|

|

797

|

+# range for tests

|

|

|

798

|

+iterations = [ 5, 10, 15, 20 ]

|

|

|

799

|

+speeds_g1 = [ 1000, 500, 200 ]

|

|

|

800

|

+

|

|

|

801

|

+def drawSquare(w, h, x, y, speed_g1):

|

|

|

802

|

+ write("G0 X" + str(x) + " Y" + str(y) + " S0 F" + str(speed_g0))

|

|

|

803

|

+ square = [

|

|

|

804

|

+ ( x + w, y ),

|

|

|

805

|

+ ( x + w, y + h ),

|

|

|

806

|

+ ( x, y + h ),

|

|

|

807

|

+ ( x, y ),

|

|

|

808

|

+ ]

|

|

|

809

|

+ for xp, yp in square:

|

|

|

810

|

+ write("G1 X" + str(xp) + " Y" + str(yp) + " S" + str(pwr) + " F" + str(speed_g1))

|

|

|

811

|

+

|

|

|

812

|

+def drawHeart(w, h, x, y, speed_g1):

|

|

|

813

|

+ heart = [

|

|

|

814

|

+ ( 0.0, 5.0 / 8.0 ),

|

|

|

815

|

+ ( 0.0, 6.0 / 8.0 ),

|

|

|

816

|

+ ( 0.1, 7.0 / 8.0 ),

|

|

|

817

|

+ ( 0.2, 8.0 / 8.0 ),

|

|

|

818

|

+ ( 0.3, 8.0 / 8.0 ),

|

|

|

819

|

+ ( 0.4, 7.0 / 8.0 ),

|

|

|

820

|

+ ( 0.5, 6.0 / 8.0 ),

|

|

|

821

|

+ ( 0.6, 7.0 / 8.0 ),

|

|

|

822

|

+ ( 0.7, 8.0 / 8.0 ),

|

|

|

823

|

+ ( 0.8, 8.0 / 8.0 ),

|

|

|

824

|

+ ( 0.9, 7.0 / 8.0 ),

|

|

|

825

|

+ ( 1.0, 6.0 / 8.0 ),

|

|

|

826

|

+ ( 1.0, 5.0 / 8.0 ),

|

|

|

827

|

+ ( 0.9, 4.0 / 8.0 ),

|

|

|

828

|

+ ( 0.8, 3.0 / 8.0 ),

|

|

|

829

|

+ ( 0.7, 2.0 / 8.0 ),

|

|

|

830

|

+ ( 0.6, 1.0 / 8.0 ),

|

|

|

831

|

+ ( 0.5, 0.0 / 8.0 ),

|

|

|

832

|

+ ( 0.4, 1.0 / 8.0 ),

|

|

|

833

|

+ ( 0.3, 2.0 / 8.0 ),

|

|

|

834

|

+ ( 0.2, 3.0 / 8.0 ),

|

|

|

835

|

+ ( 0.1, 4.0 / 8.0 ),

|

|

|

836

|

+ ( 0.0, 5.0 / 8.0 )

|

|

|

837

|

+ ]

|

|

|

838

|

+ write("G0 X" + str(x + heart[0][0] * w) + " Y" + str(y + heart[0][1] * h) + " S0 F" + str(speed_g0))

|

|

|

839

|

+ for xp, yp in heart:

|

|

|

840

|

+ write("G1 X" + str(x + xp * w) + " Y" + str(y + yp * h) + " S" + str(pwr) + " F" + str(speed_g1))

|

|

|

841

|

+

|

|

|

842

|

+def drawShape(w, h, x, y, speed_g1):

|

|

|

843

|

+ #drawSquare(w, h, x, y, speed_g1)

|

|

|

844

|

+ drawHeart(w, h, x, y, speed_g1)

|

|

|

845

|

+

|

|

|

846

|

+digits = [

|

|

|

847

|

+ [

|

|

|

848

|

+ # 0

|

|

|

849

|

+ (0.0, 0.0),

|

|

|

850

|

+ (0.0, 1.0),

|

|

|

851

|

+ (1.0, 1.0),

|

|

|

852

|

+ (1.0, 0.0),

|

|

|

853

|

+ (0.0, 0.0)

|

|

|

854

|

+ ], [

|

|

|

855

|

+ # 1

|

|

|

856

|

+ (0.5, 0.0),

|

|

|

857

|

+ (0.5, 1.0)

|

|

|

858

|

+ ], [

|

|

|

859

|

+ # 2

|

|

|

860

|

+ (0.0, 1.0),

|

|

|

861

|

+ (1.0, 1.0),

|

|

|

862

|

+ (1.0, 0.5),

|

|

|

863

|

+ (0.0, 0.5),

|

|

|

864

|

+ (0.0, 0.0),

|

|

|

865

|

+ (1.0, 0.0),

|

|

|

866

|

+ ], [

|

|

|

867

|

+ # 3

|

|

|

868

|

+ (0.0, 1.0),

|

|

|

869

|

+ (1.0, 1.0),

|

|

|

870

|

+ (1.0, 0.5),

|

|

|

871

|

+ (0.0, 0.5),

|

|

|

872

|

+ (1.0, 0.5),

|

|

|

873

|

+ (1.0, 0.0),

|

|

|

874

|

+ (0.0, 0.0),

|

|

|

875

|

+ ], [

|

|

|

876

|

+ # 4

|

|

|

877

|

+ (0.0, 1.0),

|

|

|

878

|

+ (0.0, 0.5),

|

|

|

879

|

+ (1.0, 0.5),

|

|

|

880

|

+ (1.0, 1.0),

|

|

|

881

|

+ (1.0, 0.0),

|

|

|

882

|

+ ], [

|

|

|

883

|

+ # 5

|

|

|

884

|

+ (1.0, 1.0),

|

|

|

885

|

+ (0.0, 1.0),

|

|

|

886

|

+ (0.0, 0.5),

|

|

|

887

|

+ (1.0, 0.5),

|

|

|

888

|

+ (1.0, 0.0),

|

|

|

889

|

+ (0.0, 0.0),

|

|

|

890

|

+ ], [

|

|

|

891

|

+ # 6

|

|

|

892

|

+ (1.0, 1.0),

|

|

|

893

|

+ (0.0, 1.0),

|

|

|

894

|

+ (0.0, 0.0),

|

|

|

895

|

+ (1.0, 0.0),

|

|

|

896

|

+ (1.0, 0.5),

|

|

|

897

|

+ (0.0, 0.5),

|

|

|

898

|

+ ], [

|

|

|

899

|

+ # 7

|

|

|

900

|

+ (0.0, 1.0),

|

|

|

901

|

+ (1.0, 1.0),

|

|

|

902

|

+ (1.0, 0.0),

|

|

|

903

|

+ ], [

|

|

|

904

|

+ # 8

|

|

|

905

|

+ (1.0, 0.5),

|

|

|

906

|

+ (1.0, 1.0),

|

|

|

907

|

+ (0.0, 1.0),

|

|

|

908

|

+ (0.0, 0.5),

|

|

|

909

|

+ (1.0, 0.5),

|

|

|

910

|

+ (1.0, 0.0),

|

|

|

911

|

+ (0.0, 0.0),

|

|

|

912

|

+ (0.0, 0.5),

|

|

|

913

|

+ ], [

|

|

|

914

|

+ # 9

|

|

|

915

|

+ (1.0, 0.5),

|

|

|

916

|

+ (1.0, 1.0),

|

|

|

917

|

+ (0.0, 1.0),

|

|

|

918

|

+ (0.0, 0.5),

|

|

|

919

|

+ (1.0, 0.5),

|

|

|

920

|

+ (1.0, 0.0),

|

|

|

921

|

+ (0.0, 0.0),

|

|

|

922

|

+ ]

|

|

|

923

|

+]

|

|

|

924

|

+

|

|

|

925

|

+font_w = 1.5

|

|

|

926

|

+font_h = 3.0

|

|

|

927

|

+font_d = 0.5

|

|

|

928

|

+

|

|

|

929

|

+def draw_digit(f, i, size_x, size_y, off_x, off_y):

|

|

|

930

|

+ dig = digits[i]

|

|

|

931

|

+ n = 0

|

|

|

932

|

+ for p in dig:

|

|

|

933

|

+ x, y = p

|

|

|

934

|

+ s = ""

|

|

|

935

|

+

|

|

|

936

|

+ if n == 0:

|

|

|

937

|

+ s += "G0 S0 F" + str(speed_g0)

|

|

|

938

|

+ else:

|

|

|

939

|

+ s += "G1 S" + str(pwr_num) + " F" + str(speed_g1_num)

|

|

|

940

|

+

|

|

|

941

|

+ s += " X" + str(off_x + size_x * x)

|

|

|

942

|

+ s += " Y" + str(off_y + size_y * y)

|

|

|

943

|

+

|

|

|

944

|

+ print(s)

|

|

|

945

|

+ f.write(s + "\n")

|

|

|

946

|

+ n += 1

|

|

|

947

|

+

|

|

|

948

|

+ return s

|

|

|

949

|

+

|

|

|

950

|

+def draw_number(f, n, x, y):

|

|

|

951

|

+ if n >= 1000:

|

|

|

952

|

+ draw_digit(f, int(n / 1000), font_w, font_h, x, y)

|

|

|

953

|

+ draw_digit(f, int((n / 100)) % 10, font_w, font_h, x + font_d + font_w, y)

|

|

|

954

|

+ draw_digit(f, int((n / 10) % 10), font_w, font_h, x + 2 * (font_d + font_w), y)

|

|

|

955

|

+ draw_digit(f, int(n % 10), font_w, font_h, x + 3 * (font_d + font_w), y)

|

|

|

956

|

+ elif n >= 100:

|

|

|

957

|

+ draw_digit(f, int(n / 100), font_w, font_h, x, y)

|

|

|

958

|

+ draw_digit(f, int((n / 10) % 10), font_w, font_h, x + font_d + font_w, y)

|

|

|

959

|

+ draw_digit(f, int(n % 10), font_w, font_h, x + 2 * (font_d + font_w), y)

|

|

|

960

|

+ elif n >= 10:

|

|

|

961

|

+ draw_digit(f, int(n / 10), font_w, font_h, x, y)

|

|

|

962

|

+ draw_digit(f, int(n % 10), font_w, font_h, x + font_d + font_w, y)

|

|

|

963

|

+ else:

|

|

|

964

|

+ draw_digit(f, n, font_w, font_h, x, y)

|

|

|

965

|

+

|

|

|

966

|

+with open(filename, 'w') as f:

|

|

|

967

|

+ def write(s):

|

|

|

968

|

+ print(s)

|

|

|

969

|

+ f.write(s + "\n")

|

|

|

970

|

+

|

|

|

971

|

+ # header

|

|

|

972

|

+ #write("G28")

|

|

|

973

|

+ write("G90")

|

|

|

974

|

+ write("M3 I")

|

|

|

975

|

+ write("M3 S0")

|

|

|

976

|

+ write("")

|

|

|

977

|

+

|

|

|

978

|

+ # first line is not having the power applied

|

|

|

979

|

+ # TODO

|

|

|

980

|

+ write("G0 X0 Y0 S0 F" + str(speed_g0))

|

|

|

981

|

+ write("G1 X1 Y0 S1 F" + str(speeds_g1[0]))

|

|

|

982

|

+ write("G0 X0 Y0 S0 F" + str(speed_g0))

|

|

|

983

|

+ write("G1 X0 Y1 S1 F" + str(speeds_g1[0]))

|

|

|

984

|

+ write("G0 X0 Y0 S0 F" + str(speed_g0))

|

|

|

985

|

+

|

|

|

986

|

+ max_num_str_len = 4

|

|

|

987

|

+ str_w = (max_num_str_len * font_w) + ((max_num_str_len - 1) * font_d)

|

|

|

988

|

+

|

|

|

989

|

+ write("; iterations")

|

|

|

990

|

+ for i in range(0, len(iterations)):

|

|

|

991

|

+ write("; " + str(iterations[i]))

|

|

|

992

|

+ draw_number(f, iterations[i], (width + str_w) / 2.0 + dist + i * (width + dist), 0)

|

|

|

993

|

+ write("")

|

|

|

994

|

+

|

|

|

995

|

+ write("; speeds")

|

|

|

996

|

+ for i in range(0, len(speeds_g1)):

|

|

|

997

|

+ write("; " + str(speeds_g1[i]))

|

|

|

998

|

+ draw_number(f, speeds_g1[i], 0, (height + font_h) / 2.0 + dist + i * (height + dist))

|

|

|

999

|

+

|

|

|

1000

|

+ for i in range(0, len(speeds_g1)):

|

|

|

1001

|

+ for j in range(0, len(iterations)):

|

|

|

1002

|

+ write("; speed=" + str(speeds_g1[i]) + " n=" + str(iterations[j]))

|

|

|

1003

|

+ for k in range(0, iterations[j]):

|

|

|

1004

|

+ drawShape(width, height, str_w + dist + j * (width + dist), font_h + dist + i * (height + dist), speeds_g1[i])

|

|

|

1005

|

+ write("")

|

|

|

1006

|

+

|

|

|

1007

|

+ # footer

|

|

|

1008

|

+ write("M5")

|

|

|

1009

|

+ write("G0 X0 Y0 F" + str(speed_g0))

|

|

|

1010

|

+</pre>

|

|

|

1011

|

+

|

|

|

1012

|

+I'm drawing digits again, like in the Grid G-Code generator above.

|

|

|

1013

|

+It seems I need to create some kind of library or so if I continue this route of generating G-Code.

|

|

|

1014

|

+

|

|

|

1015

|

+<!--%

|

|

|

1016

|

+lightgallery([

|

|

|

1017

|

+ [ "img/laser_cut_test_1.jpg", "Test sheet being cut" ],

|

|

|

1018

|

+ [ "img/laser_cut_test_3.jpg", "Finished test run" ],

|

|

|

1019

|

+])

|

|

|

1020

|

+%-->

|

|

|

1021

|

+

|

|

|

1022

|

+In the pictures above, the 3x3 grid of hearts on the right was made with the laser slightly out of focus.

|

|

|

1023

|

+It was not able to cut through in this run, even with 30 iterations.

|

|

|

1024

|

+I also still had the text not aligned properly.

|

|

|

1025

|

+

|

|

|

1026

|

+The 3x1 and 3x3 runs on the left side were made after properly focussing the laser and fixing the text alignment.

|

|

|

1027

|

+Here 200mm/min with 10 iterations was already enough to cut through the 3mm plywood.

|

|

|

1028

|

+

|

|

|

1029

|

+## Cutting Tests

|

|

|

1030

|

+<a class="anchor" name="cutting_tests"></a>

|

|

|

1031

|

+

|

|

|

1032

|

+For the first 'real' test I decided to cut the assembly jig for the [Pagoda antenna](https://www.maartenbaert.be/quadcopters/antennas/pagoda-antenna/#design-files) by Maarten Baert.

|

|

|

1033

|

+The files are available in dxf and svg format.

|

|

|

1034

|

+I was able to easily import the svg file in LaserGRBL to create G-Code, afterwards converting it to the proper format using my script described above.

|

|

|

1035

|

+

|

|

|

1036

|

+<!--%

|

|

|

1037

|

+lightgallery([

|

|

|

1038

|

+ [ "img/laser_pagoda_1.jpg", "Front side of the Pagoda jig sheet" ],

|

|

|

1039

|

+ [ "img/laser_pagoda_2.jpg", "Back side of the Pagoda jig sheet" ],

|

|

|

1040

|

+ [ "img/laser_pagoda_3.jpg", "Assembled Pagoda antenna jig" ],

|

|

|

1041

|

+])

|

|

|

1042

|

+%-->

|

|

|

1043

|

+

|

|

|

1044

|

+As in one of my previous tests I used 200mm/min with 10 iterations.

|

|

|

1045

|

+But this was not quite enough to get the parts out easily.

|

|

|

1046

|

+In hindsight I should have used at least 15 iterations.

|

|

|

1047

|

+But the result was still usable, even with only 10 iterations.

|

|

|

1048

|

+

|

|

|

1049

|

+Next my SO requested some christmas decoration, so I decided to attempt to cut this [Christmas Tree Ornament](https://www.thingiverse.com/thing:43041) by TomKeddie on Thingiverse.

|

|

|

1050

|

+It is made for 4.8mm plywood, so I scaled it down by a factor of `3.0 / 4.8 = 0.625`.

|

|

|

1051

|

+The design comes as a dxf file, so I imported that in Inkscape and then exported an svg file from that.

|

|

|

1052

|

+This I then imported in LaserGRBL, generated G-Code and converted that using the script above.

|

|

|

1053

|

+

|

|

|

1054

|

+<!--%

|

|

|

1055

|

+lightgallery([

|

|

|

1056

|

+ [ "img/laser_tree_test.mp4", "video/mp4", "", "", "Cutting a christmas tree decoration" ],

|

|

|

1057

|

+ [ "img/laser_tree_segments.mp4", "video/mp4", "", "", "Segmented lines while cutting" ],

|

|

|

1058

|

+])

|

|

|

1059

|

+%-->

|

|

|

1060

|

+

|

|

|

1061

|

+As you can tell from the second video, what should be single continuous lines has instead sometimes been split up into many small path segments, which LaserGRBL is cutting in non-optimal ordering.

|

|

|

1062

|

+I have not yet found a way to easily clean these paths up.

|

|

|

1063

|

+

|

|

|

1064

|

+<!--%

|

|

|

1065

|

+lightgallery([

|

|

|

1066

|

+ [ "img/laser_tree_1.jpg", "Front side of christmas tree sheet" ],

|

|

|

1067

|

+ [ "img/laser_tree_2.jpg", "Back side of christmas tree sheet" ],

|

|

|

1068

|

+ [ "img/laser_tree_3.jpg", "Finished christmas tree ornament" ],

|

|

|

1069

|

+])

|

|

|

1070

|

+%-->

|

|

|

1071

|

+

|

|

|

1072

|

+The end-result does not seem to be really affected by this however, although with 200mm/min and 15 iterations the parts were not removable as easily as I hoped.

|

|

|

1073

|

+So I think I either have to adjust the focus better or go up to 20 iterations for the 3mm birch plywood.

|

|

|

1074

|

+

|

|

|

1075

|

+## Future Improvements

|

|

|

1076

|

+<a class="anchor" name="future_improvements"></a>

|

|

|

1077

|

+

|

|

|

1078

|

+I didn't expect it to be this bad, but cutting wood really produces a noticeable amount of smoke and the smell of burnt wood.

|

|

|

1079

|

+So in the long run I will have to add some kind of air filtration system to my Ikea Lack tower.

|

|

|

1080

|

+Also I now better understand the need for Air Assist on laser cutters.

|

|

|

1081

|

+My small fans don't help much in keeping the light-path free of smoke and soot.

|

|

|

1082

|

+But I will hopefully get away with running it for a while without these additions.

|

|

|

1083

|

+

|

|

|

1084

|

+Another obvious improvement is the addition of a Raspberry Pi and a Webcam, to allow remote monitoring of long-running jobs.

|

|

|

1085

|

+I also came across the [LaserWeb project](https://laserweb.yurl.ch/) which seems to be similar in spirit to OctoPrint for 3D printers, but also with the ability of processing vector and bitmap files from within the web interface.

|

|

|

1086

|

+This would be a very useful addition and solve a lot of the software workflow problems illustrated above.

|

|

|

1087

|

+Also theres more than enough room left on my base plate for a SBC.

|

|

|

1088

|

+

|

|

|

1089

|

+## Cutting Parameters

|

|

|

1090

|

+<a class="anchor" name="cutting_parameters"></a>

|

|

|

1091

|

+

|

|

|

1092

|

+Here are the results of all cutting tests I've made up to now.

|

|

|

1093

|

+I will update this table as soon as I gather new data 🧑🔬

|

|

|

1094

|

+

|

|

|

1095

|

+<!--%

|

|

|

1096

|

+tableHelper([ "align-right", "align-right", "align-right", "align-right", "align-right", "align-right", "align-right", "align-left", "align-left" ],

|

|

|

1097

|

+ [ "Type", "Material", "Thickness<br><span style=\"font-size: small;\">(in mm)</span>", "Power<br><span style=\"font-size: small;\">(in W)</span>", "PWM<br><span style=\"font-size: small;\">(out of 255)</span>", "Speed<br><span style=\"font-size: small;\">(in mm/min)</span>", "Iterations", "Remarks", "Date" ], [

|

|

|

1098

|

+ [ "<s>Plywood</s>", "<s>Birch</s>", "<s>3</s>", "<s>2.5</s>", "<s>255</s>", "<s>200</s>", "<s>5</s>", "<s>Not possible to remove.</s>", "<s>2022-11-24</s>" ],

|

|

|

1099

|

+ [ "Plywood", "Birch", "3", "2.5", "255", "200", "10", "Difficult to remove.", "2022-11-24" ],

|

|

|

1100

|

+ [ "Plywood", "Birch", "3", "2.5", "255", "200", "15", "Easily removable.", "2022-11-24" ],

|

|

|

1101

|

+ [ "Plywood", "Birch", "3", "2.5", "255", "200", "20", "Freely fell out.", "2022-11-24" ],

|

|

|

1102

|

+ [ "<s>Plywood</s>", "<s>Birch</s>", "<s>3</s>", "<s>2.5</s>", "<s>255</s>", "<s>500</s>", "<s>15</s>", "<s>Not possible to remove.</s>", "<s>2022-11-24</s>" ],

|

|

|

1103

|

+ [ "Plywood", "Birch", "3", "2.5", "255", "500", "20", "Difficult to remove.", "2022-11-24" ],

|

|

|

1104

|

+ [ "Plywood", "Birch", "3", "2.5", "255", "200", "15", "Difficult to remove.", "2022-11-25" ],

|

|

|

1105

|

+ ]

|

|

|

1106

|

+)

|

|

|

1107

|

+%-->

|

|

|

1108

|

+

|

|

531

|

1109

|

## More Pictures

|

|

|

1110

|

+<a class="anchor" name="more_pictures"></a>

|

|

532

|

1111

|

|

|

533

|

1112

|

<div class="collapse">Some more photographs I didn't use above.</div>

|

|

534

|

1113

|

<div class="collapsecontent">

|

|

535

|

1114

|

<!--%

|

|

536

|

1115

|

lightgallery([

|

|

537

|

1116

|

[ "img/laser_tower_2.jpg", "Frontal view in Ikea Lack tower" ],

|

|

|

1117

|

+ [ "img/laser_cut_test_2.jpg", "Finished test run" ],

|

|

538

|

1118

|

[ "img/laser_gt2560.jpg", "GT2560 mainboard of laser engraver" ],

|

|

539

|

1119

|

])

|

|

540

|

1120

|

%-->

|