|

|

@@ -22,7 +22,31 @@ Of course, as with every printer, there were some rough spots and problems, but

|

|

22

|

22

|

|

|

23

|

23

|

TODO photos

|

|

24

|

24

|

|

|

25

|

|

-### Power Supply Replacement

|

|

|

25

|

+## Spool mount

|

|

|

26

|

+

|

|

|

27

|

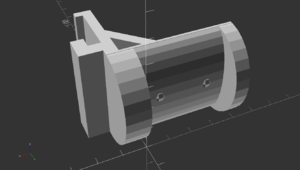

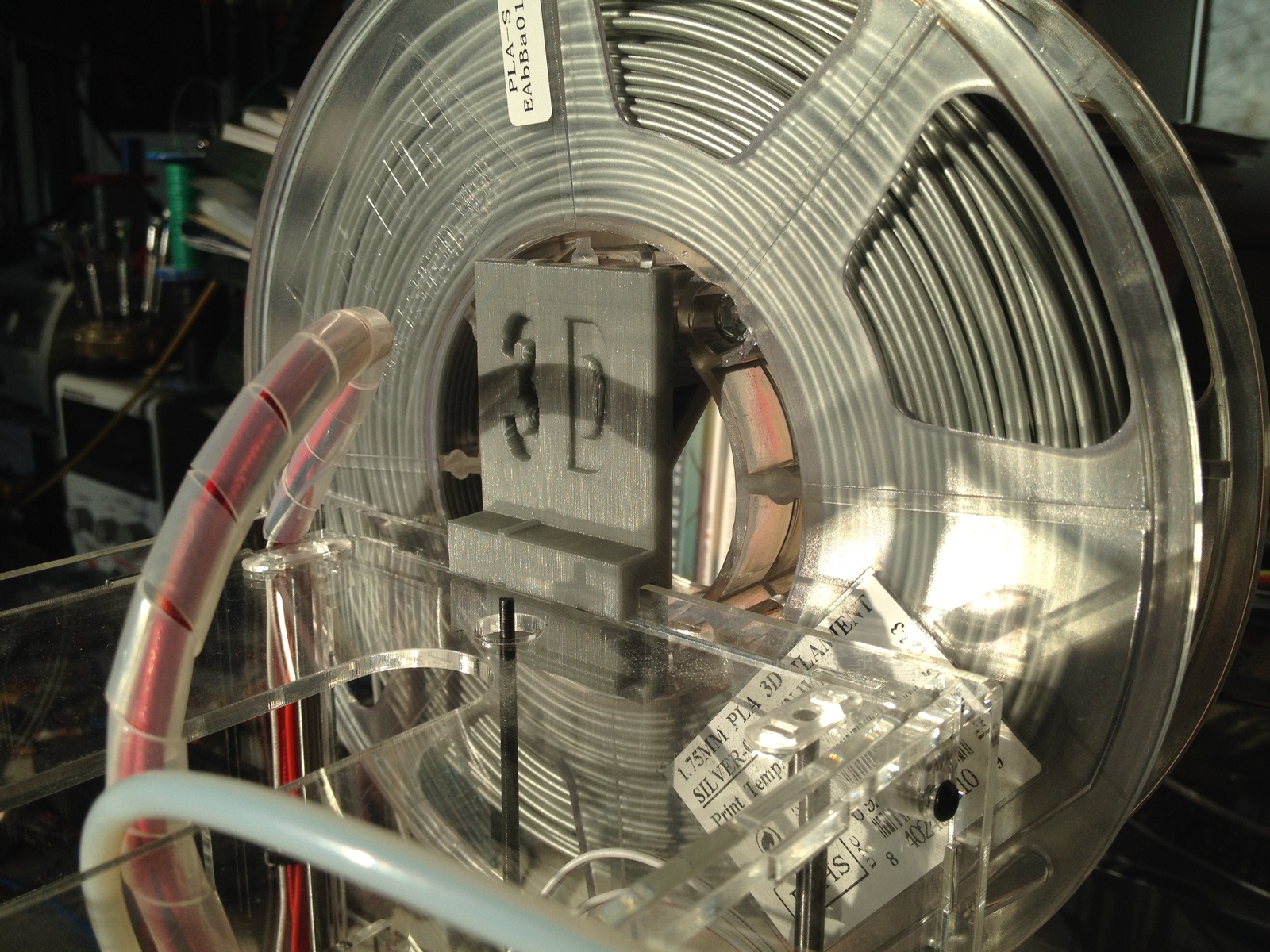

+One of the first problems I ran into was mounting the filament spool.

|

|

|

28

|

+I found a [ready-made solution on Thingiverse](https://www.thingiverse.com/thing:1057433), which I was using for a while, until I switched to a different brand whose spool did no longer fit.

|

|

|

29

|

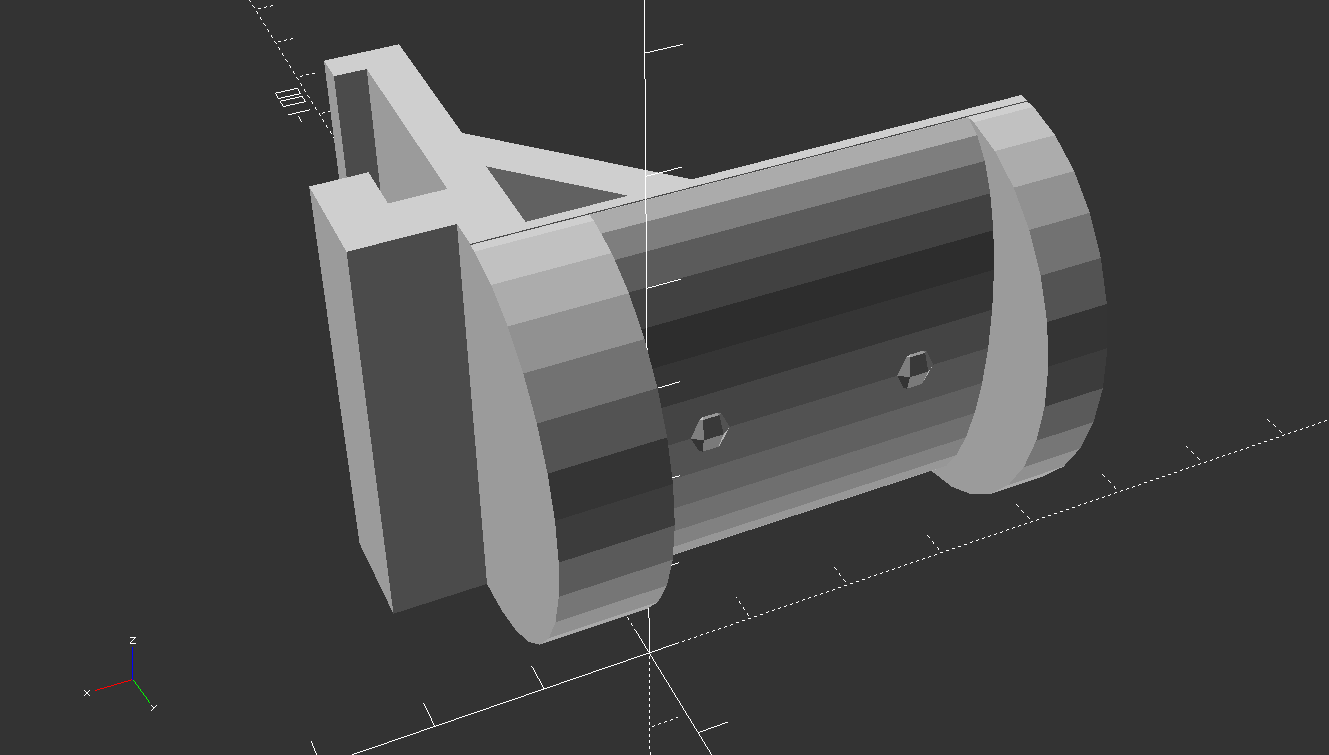

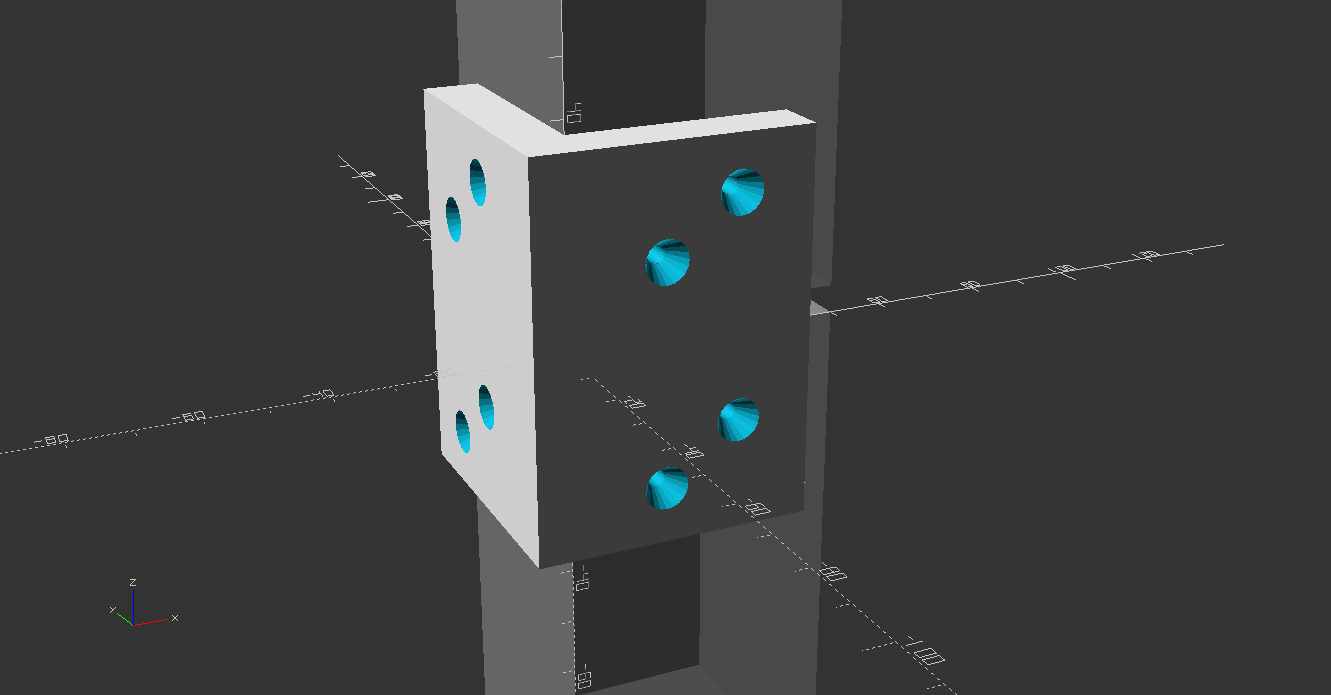

+Because of that, [I designed my own holder](https://www.thingiverse.com/thing:1427890).

|

|

|

30

|

+

|

|

|

31

|

+<!--%

|

|

|

32

|

+lightgallery([

|

|

|

33

|

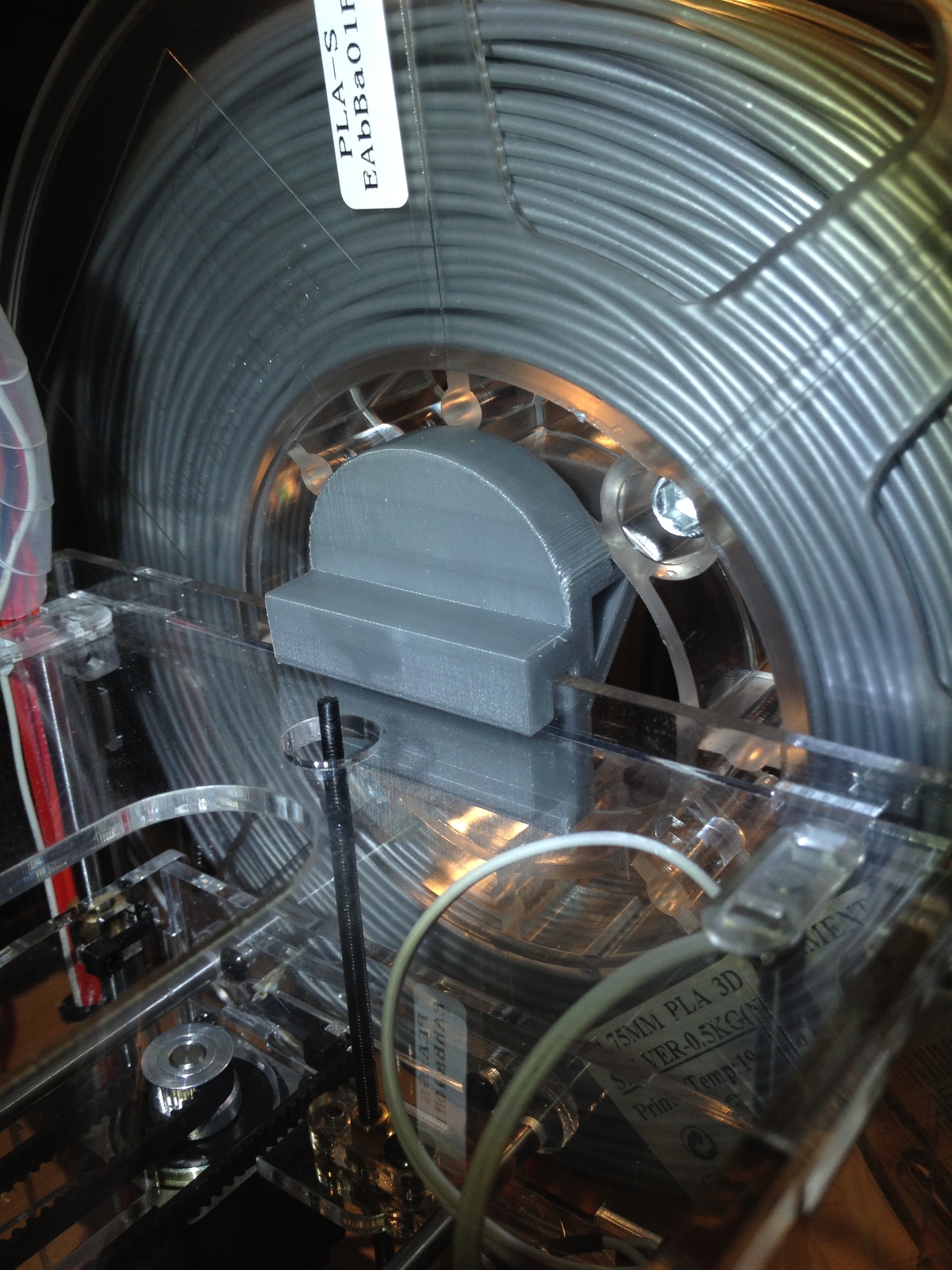

+ [ "img/fabmin_spool_1.jpg", "My spool holder" ],

|

|

|

34

|

+ [ "img/fabmin_spool_2.png", "Design of my spool holder" ],

|

|

|

35

|

+ [ "img/fabmin_spool_3.jpg", "Spool holder on printer" ],

|

|

|

36

|

+ [ "img/fabmin_spool_4.jpg", "Original I modeled mine after" ]

|

|

|

37

|

+])

|

|

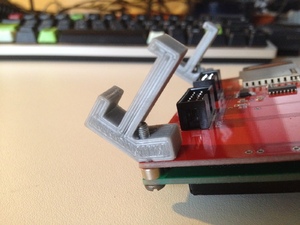

|

38

|

+%-->

|

|

|

39

|

+

|

|

|

40

|

+## Feet

|

|

|

41

|

+

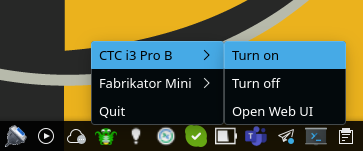

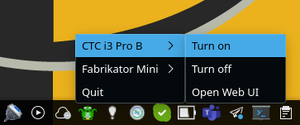

|

|

|

42

|

+With a heavy filament spool mounted on the backside of the printer, it was no longer standing upright.

|

|

|

43

|

+Because of that, bigger feet were needed.

|

|

|

44

|

+Luckily, there was also [something available already](https://www.thingiverse.com/thing:1396469).

|

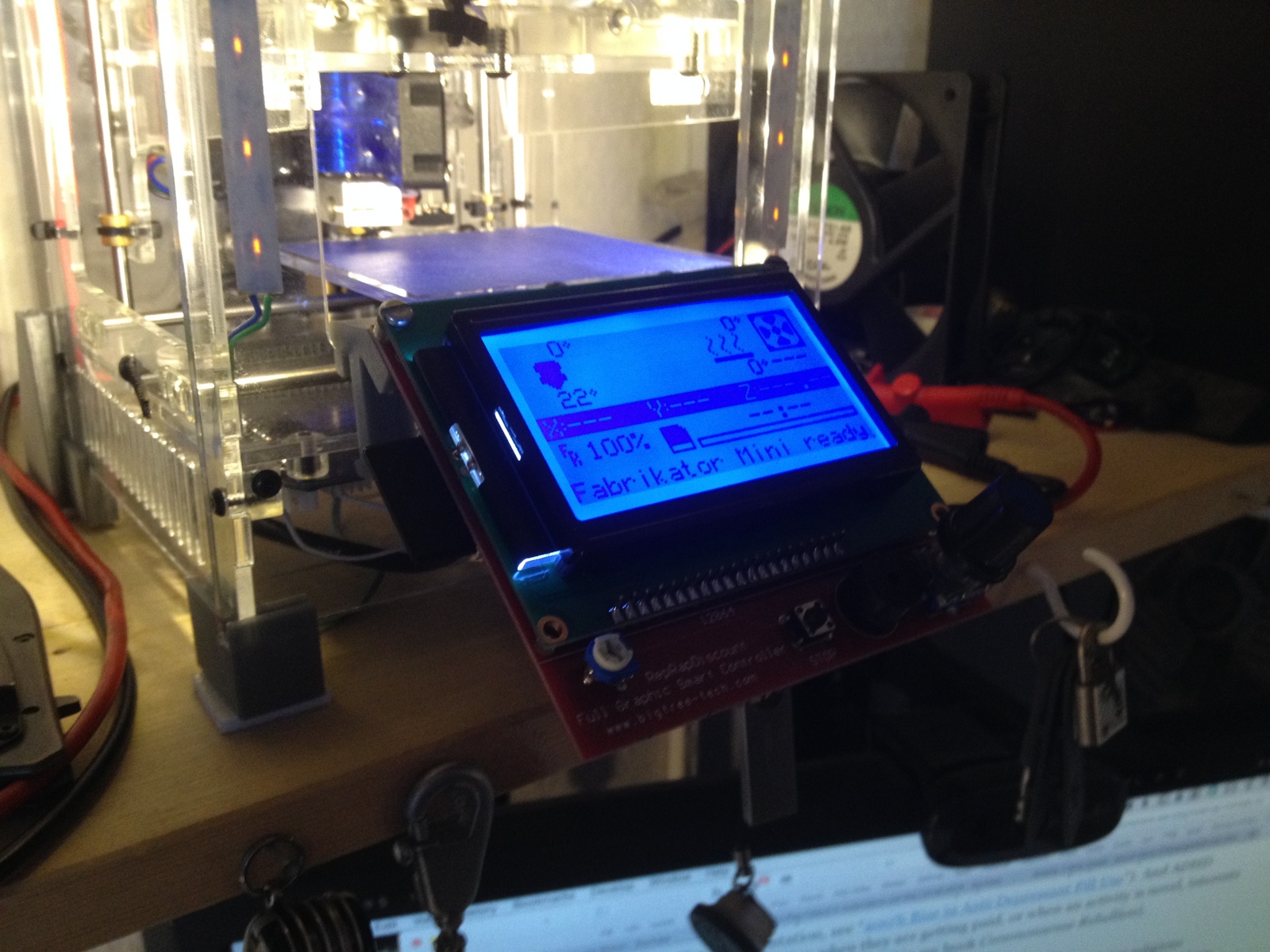

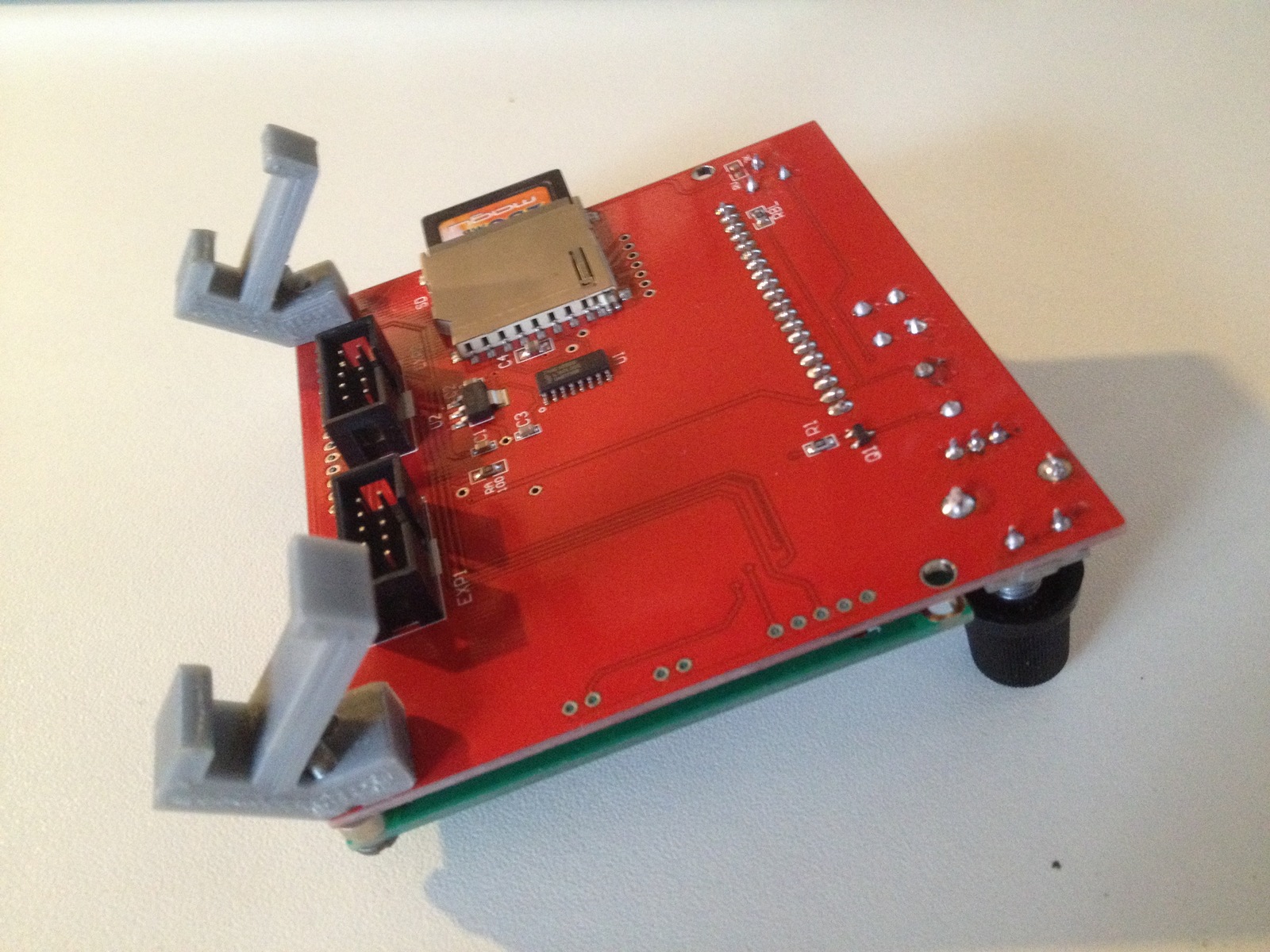

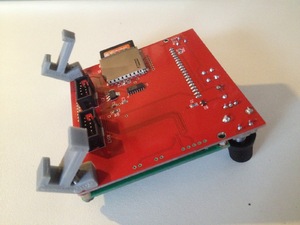

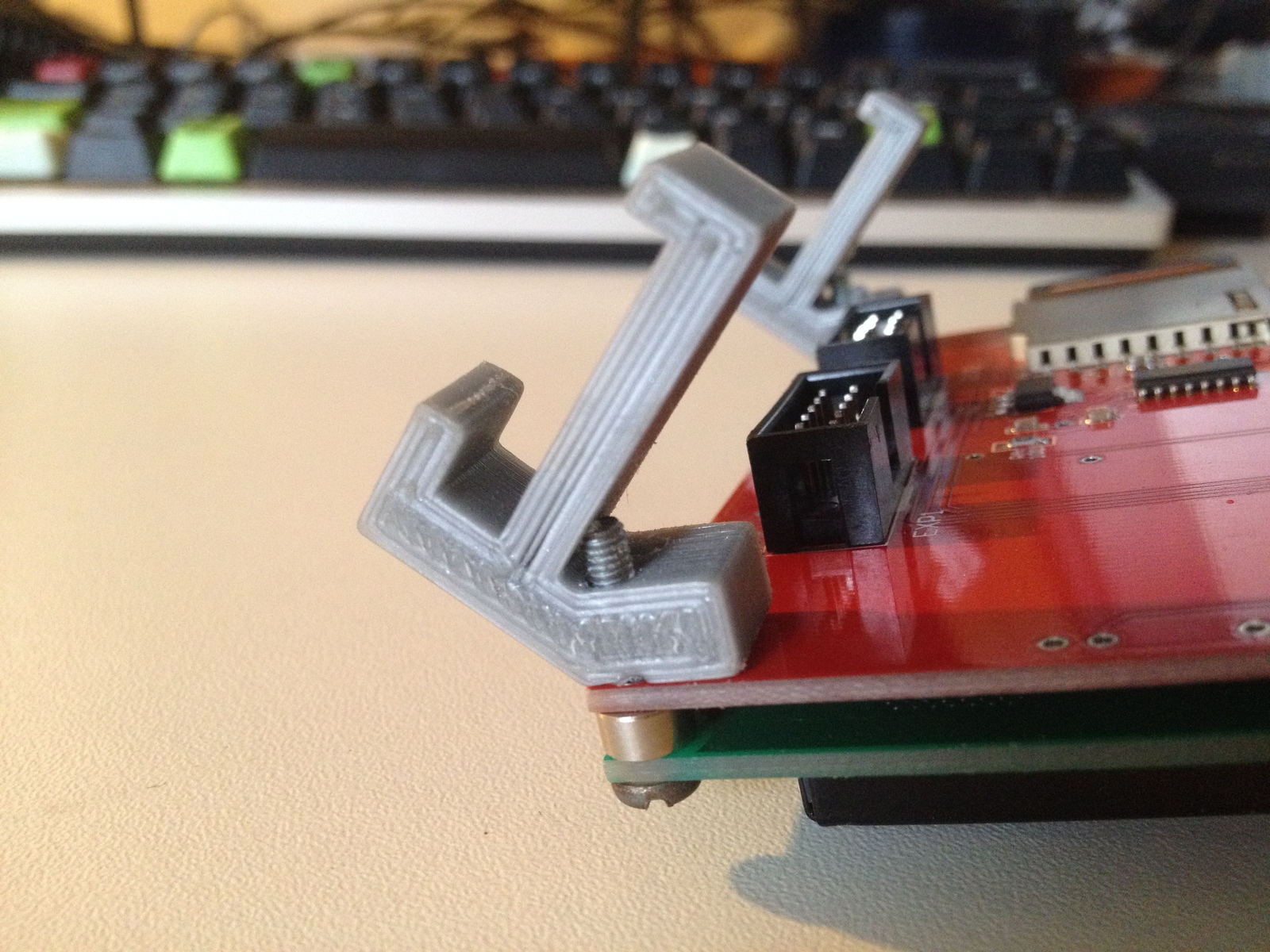

|

|

45

|

+I just had to [cut a bit off in OpenSCAD]() to get matching front feet.

|

|

|

46

|

+

|

|

|

47

|

+TODO photos

|

|

|

48

|

+

|

|

|

49

|

+## Power Supply Replacement

|

|

26

|

50

|

|

|

27

|

51

|

I did not really trust the stock power supply and I also needed more power available for further modifications.

|

|

28

|

52

|

So one of the first steps was replacing the power supply.

|

|

|

@@ -34,13 +58,13 @@ In my configuration, the power supply is always turned on, powering the Raspberr

|

|

34

|

58

|

|

|

35

|

59

|

TODO photos

|

|

36

|

60

|

|

|

37

|

|

-### Heatbed Replacement

|

|

|

61

|

+## Heatbed Replacement

|

|

38

|

62

|

|

|

39

|

63

|

One of the first problems I ran into were with the printing surface.

|

|

40

|

64

|

In its stock configuration, the Fabrikator Mini has an acrylic sheet with blue painters masking tape on top as its print surface.

|

|

41

|

65

|

This works, but I was not entirely happy with the adhesion of PLA and the need to frequently replace the tape or even use stuff like glue or hairspray to keep the prints firmly in place.

|

|

42

|

66

|

So I did a search on eBay, and found a vendor offering replacement aluminum heatbeds specifically for the Fabrikator Mini. They were made `tinyfab.xyz`, they now have their own [webshop listing the heatbed](https://www.tinyfab.xyz/product-page/mini-fabrikator-v1-1-5-alu-heatbed). Unfortunately, it no longer seems to be available.

|

|

43

|

|

-I've also bough a 80mm wide kapton tape roll and have been using this as a print surface on the aluminum heatbed ever since, only replacing it when needed after I damaged it on print removal.

|

|

|

67

|

+I've also bought a 80mm wide kapton tape roll and have been using this as a print surface on the aluminum heatbed ever since, only replacing it when needed after I damaged it on print removal.

|

|

44

|

68

|

Depending on how you solder the power supply wires to the heatbed, it can either run in a 15W or a 60W configuration.

|

|

45

|

69

|

I found the 15W setting to be painfully slow in reaching usable temperatures, so I have been using the 60W variant basically from the beginning.

|

|

46

|

70

|

Of course, as mentioned before, I used a beefier power supply for this that can handle the load. I did not however replace the DC connector on the printer or use a MOSFET or anything special. Both the connector and the (in stock unused) heatbed MOSFET seem to be able to handle the load in my configuration, even for very long prints.

|

|

|

@@ -48,7 +72,17 @@ I did have some problems with properly routing the cables for the heatbed, a cou

|

|

48

|

72

|

|

|

49

|

73

|

TODO photos

|

|

50

|

74

|

|

|

51

|

|

-### Mesh Bed Leveling

|

|

|

75

|

+## Custom Firmware

|

|

|

76

|

+

|

|

|

77

|

+Luckily the main board already has a MOSFET for the heated print bed that was unused in the original setup.

|

|

|

78

|

+But of course, to enable support for the heatbed, I had to compile my own custom Marlin firmware.

|

|

|

79

|

+This is also recommended for safety reasons, as the chinese manufacturers often leave out the temperature runaway shutoff in their firmware config.

|

|

|

80

|

+

|

|

|

81

|

+

|

|

|

82

|

+

|

|

|

83

|

+I also wrote [this blog post](2016_03_24_marlin_fabrikator_mini.html) about my Marlin modifications.

|

|

|

84

|

+

|

|

|

85

|

+## Mesh Bed Leveling

|

|

52

|

86

|

|

|

53

|

87

|

Even though it probably shouldn't be necessary for such a small printbed, I did still have some first layer adhesion issues with the aluminum printbed. Especially one corner seems to be a bit bent. So I enabled Mesh Bed Leveling in my Marlin Firwmare (see below) and also wrote a little [GUI Tool to assist the leveling process](https://git.xythobuz.de/thomas/Bed-Leveling-Utility). It is also on [GitHub](https://github.com/xythobuz/Bed-Leveling-Utility).

|

|

54

|

88

|

|

|

|

@@ -62,7 +96,7 @@ Here is my latest measured mesh, for example. Also be aware that these values di

|

|

62

|

96

|

|

|

63

|

97

|

And this is really just an example! Do not just copy these values to your printer, they will differ of course.

|

|

64

|

98

|

|

|

65

|

|

-### Temperature Issues

|

|

|

99

|

+## Temperature Issues

|

|

66

|

100

|

|

|

67

|

101

|

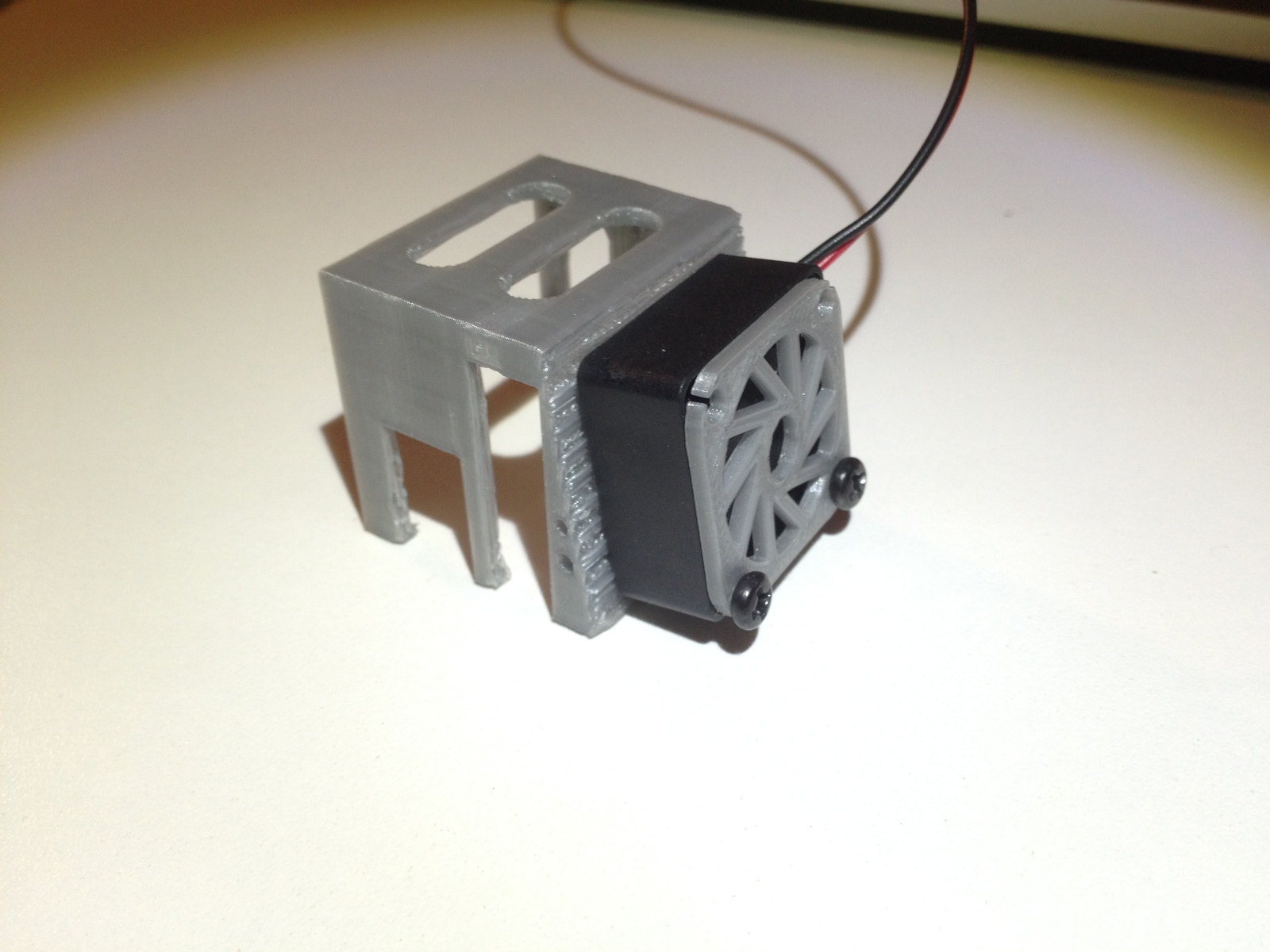

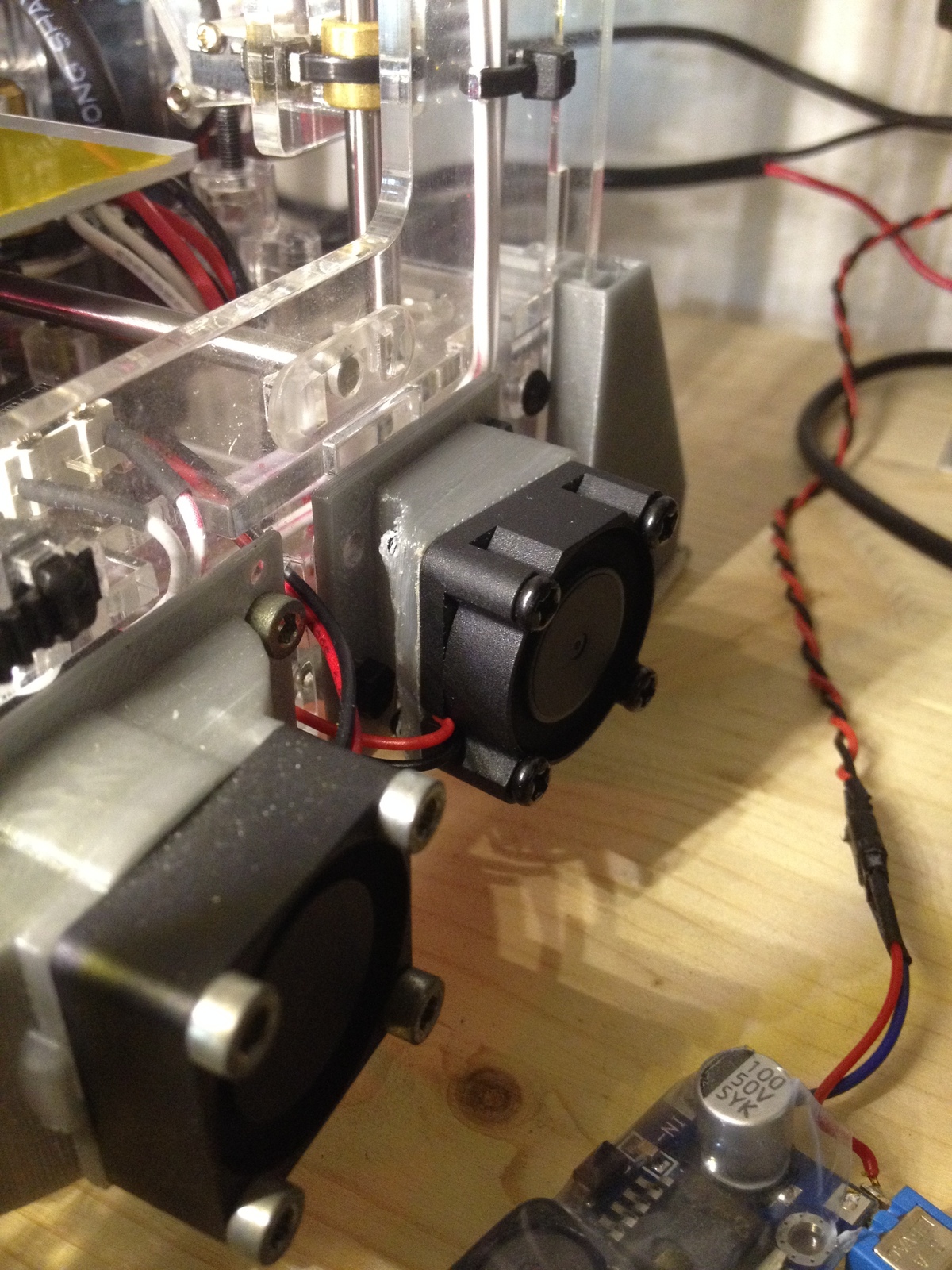

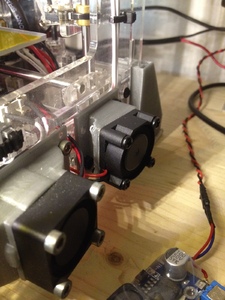

With all of this added load, and even in its stock configuration, the Fabrikator Mini electronics and stepper motors run very hot.

|

|

68

|

102

|

So hot that I did not feel comfortable leaving it like this.

|

|

|

@@ -76,9 +110,18 @@ Here are the link to the fan mount designs:

|

|

76

|

110

|

* [Y-Axis motor fan](https://www.thingiverse.com/thing:1454399)

|

|

77

|

111

|

* [Z-Axis motor fan](https://www.thingiverse.com/thing:1531538)

|

|

78

|

112

|

|

|

79

|

|

-TODO photos

|

|

|

113

|

+<!--%

|

|

|

114

|

+lightgallery([

|

|

|

115

|

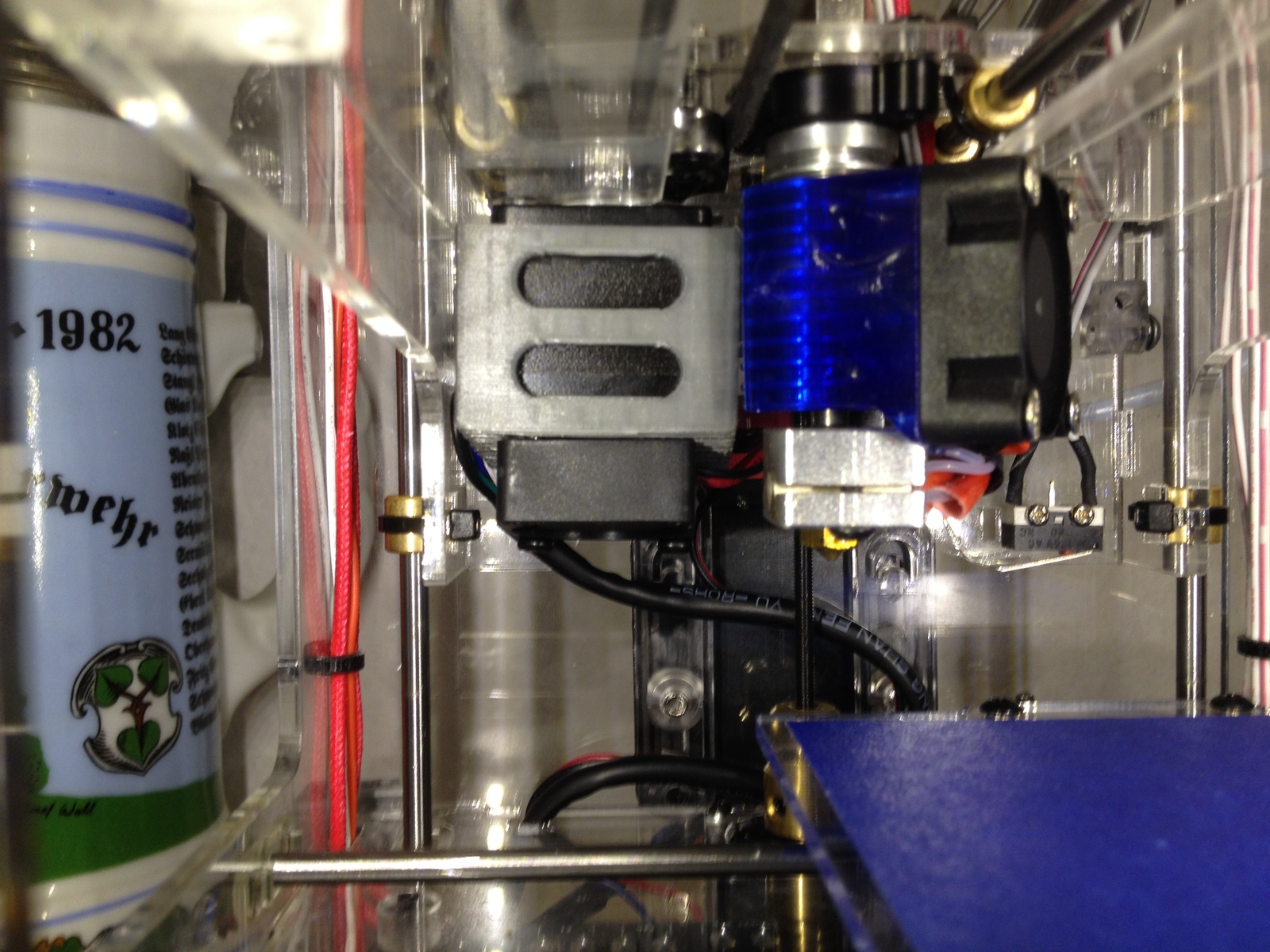

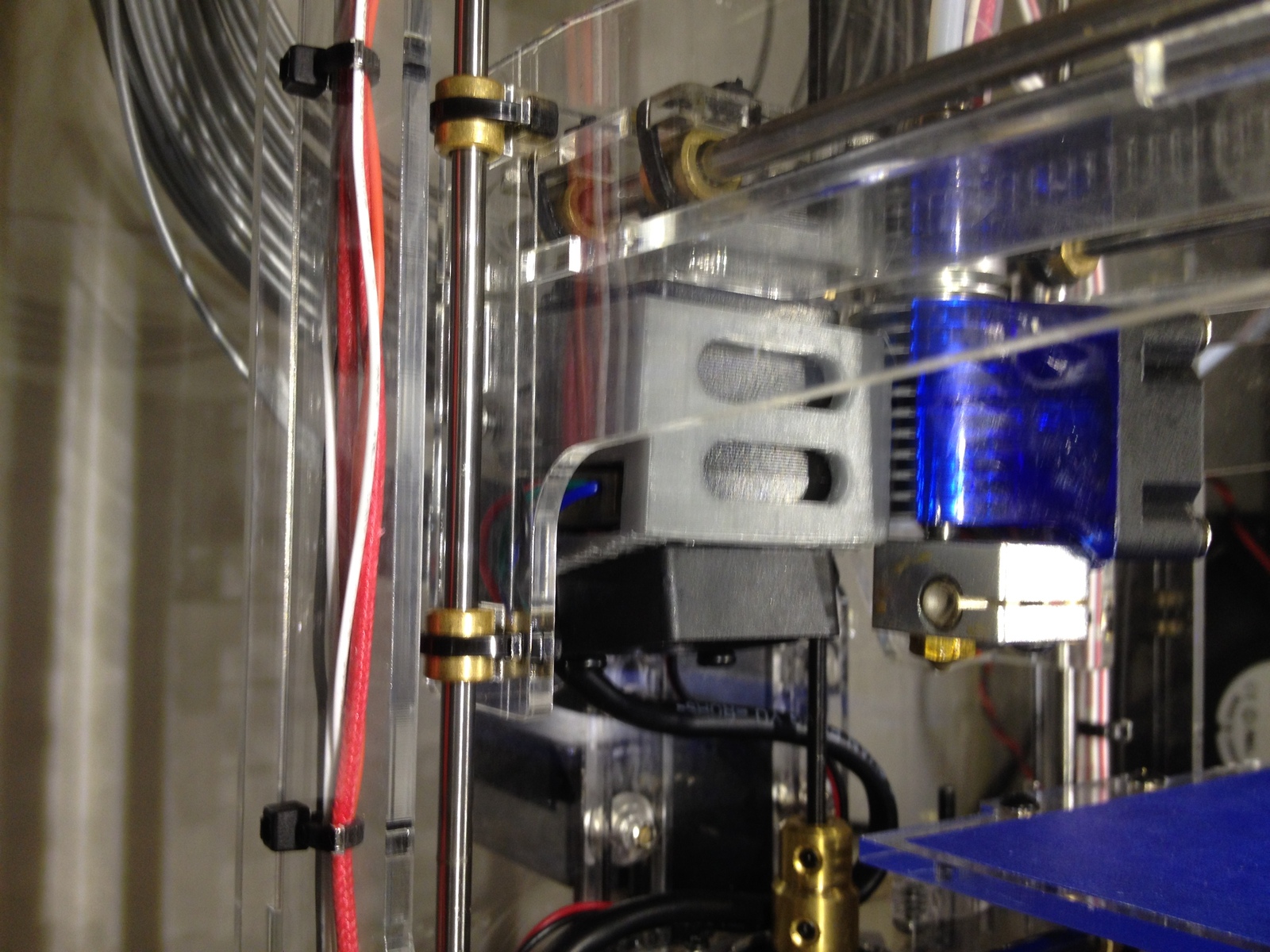

+ [ "img/fabmin_yfan_1.jpg", "Y-axis fan" ],

|

|

|

116

|

+ [ "img/fabmin_yfan_2.jpg", "Y-axis fan" ],

|

|

|

117

|

+ [ "img/fabmin_yfan_3.jpg", "Y-axis fan" ],

|

|

|

118

|

+ [ "img/fabmin_yfan_4.jpg", "Y-axis fan" ],

|

|

|

119

|

+ [ "img/fabmin_yfan_5.jpg", "Y-axis fan" ],

|

|

|

120

|

+ [ "img/fabmin_zfan_1.jpg", "Z-axis fan" ]

|

|

|

121

|

+])

|

|

|

122

|

+%-->

|

|

80

|

123

|

|

|

81

|

|

-### Z-Axis Noise and Wobble

|

|

|

124

|

+## Z-Axis Noise and Wobble

|

|

82

|

125

|

|

|

83

|

126

|

Right from the start I noticed a very painful high-pitched squealing noise coming from the Z-axis whenever it moved.

|

|

84

|

127

|

Even with lubrication I was not able to resolve this.

|

|

|

@@ -90,7 +133,7 @@ It does in fact stop the noise, and fortunately I cannot notice or measure any z

|

|

90

|

133

|

|

|

91

|

134

|

TODO photo

|

|

92

|

135

|

|

|

93

|

|

-### Part Cooling Fan

|

|

|

136

|

+## Part Cooling Fan

|

|

94

|

137

|

|

|

95

|

138

|

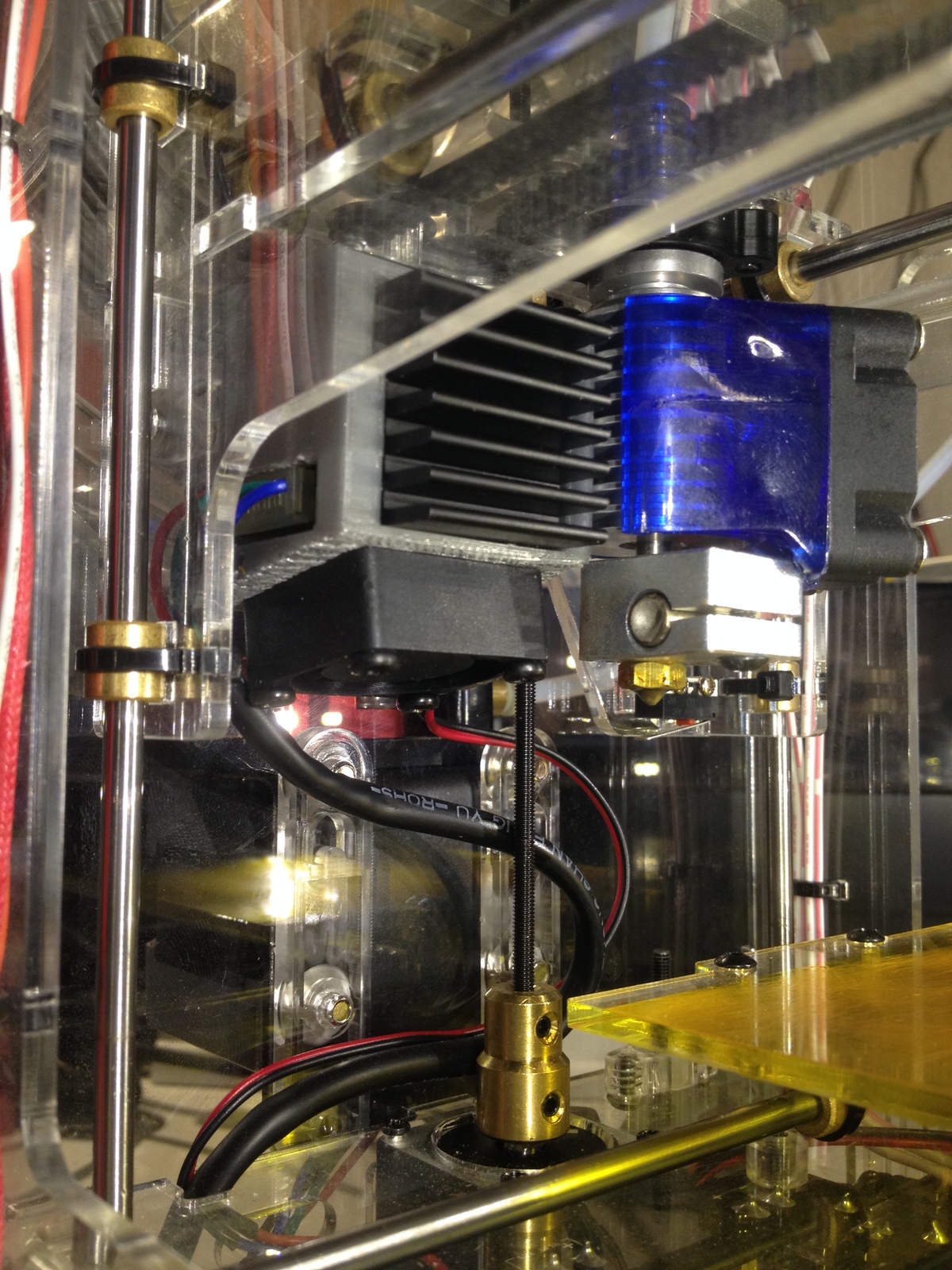

Even though print results were already pretty good, there was still some sagging noticeable on sections with long bridges, and also some stringing issues.

|

|

96

|

139

|

Of course, the only real solution for these issues with PLA is a part cooling fan.

|

|

|

@@ -101,16 +144,22 @@ TODO photo

|

|

101

|

144

|

|

|

102

|

145

|

TODO wiring hotend heatbed part-fan hotend-fan

|

|

103

|

146

|

|

|

104

|

|

-### Full Graphics Smart LCD

|

|

|

147

|

+## Full Graphics Smart LCD

|

|

105

|

148

|

|

|

106

|

149

|

To be able to properly control the printer and print from the SD Card (before I was using OctoPrint), it is very useful to install some kind of display for status informations and changing settings on-the-fly.

|

|

107

|

|

-One of the most common solutions there is the [Full Graphics Smart Controller](https://reprap.org/wiki/RepRapDiscount_Full_Graphic_Smart_Controller) that is available as cheap chinese clones easily.

|

|

|

150

|

+One of the most common solutions out there is the [Full Graphics Smart Controller](https://reprap.org/wiki/RepRapDiscount_Full_Graphic_Smart_Controller) that is available as cheap chinese clones easily.

|

|

108

|

151

|

As there was no good mounting solution available that could also be printed with the Fabrikator Mini itself, I designed [these small mounting brackets](https://www.thingiverse.com/thing:1441146) to hang the display from the front acrylic plate cutout of the machine.

|

|

109

|

152

|

The controller board already has connectors available for the LCD. Just take care that the pinout matches, if I remember correctly I had to switch the connectors around.

|

|

110

|

153

|

|

|

111

|

|

-TODO photo

|

|

|

154

|

+<!--%

|

|

|

155

|

+lightgallery([

|

|

|

156

|

+ [ "img/fabmin_disp_1.jpg", "Full Graphics Smart LCD on Fabrikator Mini" ],

|

|

|

157

|

+ [ "img/fabmin_disp_2.jpg", "Mounting brackets, far view" ],

|

|

|

158

|

+ [ "img/fabmin_disp_3.jpg", "Mounting brackets, near view" ]

|

|

|

159

|

+])

|

|

|

160

|

+%-->

|

|

112

|

161

|

|

|

113

|

|

-### Raspberry Pi Zero

|

|

|

162

|

+## Raspberry Pi Zero

|

|

114

|

163

|

|

|

115

|

164

|

Of course, to really properly utilize a 3D printer, you need OctoPrint!

|

|

116

|

165

|

This is normally used in conjunction with a Raspberry Pi connected to the printer.

|

|

|

@@ -119,23 +168,26 @@ I had it lying around without a useful project and the formfactor matches the sm

|

|

119

|

168

|

As it is also printing very slowly, there's really not much load on the Pi itself, and I never had any problems printing from it.

|

|

120

|

169

|

I do have to admit however, that the OctoPrint webinterface sometimes takes very long to load with this setup.

|

|

121

|

170

|

But once it's there it works fine.

|

|

122

|

|

-I'm even doing all my slicing for the Fabrikator Mini on the Pi Zero.

|

|

|

171

|

+I was even doing all my slicing for the Fabrikator Mini on the Pi Zero for a while.

|

|

123

|

172

|

|

|

124

|

|

-TODO describe power supply situation for Pi, with modded USB cable

|

|

|

173

|

+To power the Pi, I'm using a small 5V step down converter that's connected to the 12V input of the printer.

|

|

|

174

|

+As the printer board is also connected to 12V and has its own 5V regulator, I decided to cut the +5V rail in the USB cable connecting the printer and the Pi.

|

|

|

175

|

+This way, the display backlight on my printer, as well as the mainboard, are turned off when the power supply relais is turned off.

|

|

|

176

|

+With an unmodified cable, the printer LEDs would be lit all the time the Pi is running.

|

|

125

|

177

|

|

|

126

|

178

|

TODO photo

|

|

127

|

179

|

|

|

128

|

|

-### Relay Board

|

|

|

180

|

+## Relay Board

|

|

129

|

181

|

|

|

130

|

182

|

To fully utilize OctoPrint, it also needs a way to control the power supply to the printer.

|

|

131

|

183

|

One popular method to achieve this is an ATX computer power supply.

|

|

132

|

184

|

As I already had my power supply, and because the current of the small Fabrikator Mini is not that huge (and it's not switched under full load), I decided to use a simple two-channel relay board connected to the Pi.

|

|

133

|

185

|

|

|

134

|

|

-TODO more text or link to OctoPrint page section?

|

|

|

186

|

+Some more about controlling power supplies from OctoPrint [can be found on this page about my OctoPrint setups](octoprint.html).

|

|

135

|

187

|

|

|

136

|

188

|

TODO photo

|

|

137

|

189

|

|

|

138

|

|

-### Webcam

|

|

|

190

|

+## Webcam

|

|

139

|

191

|

|

|

140

|

192

|

No OctoPrint experience is complete without having a webcam connected to the Raspberry Pi.

|

|

141

|

193

|

So I bought the, in my view, standard model for 3D printing needs: the Logitech C270.

|

|

|

@@ -147,9 +199,13 @@ So one of my first self-made designs became the Webam Holder: an attachment piec

|

|

147

|

199

|

* [Logitech C270 Manual Focus System](https://www.thingiverse.com/thing:3081838)

|

|

148

|

200

|

* [Fabrikator Mini C270 Webcam Holder](https://www.thingiverse.com/thing:1531522)

|

|

149

|

201

|

|

|

150

|

|

-TODO photos

|

|

|

202

|

+<!--%

|

|

|

203

|

+lightgallery([

|

|

|

204

|

+ [ "img/fabmin_webcam_1.jpg", "My webcam holder" ]

|

|

|

205

|

+])

|

|

|

206

|

+%-->

|

|

151

|

207

|

|

|

152

|

|

-### LED-Strip

|

|

|

208

|

+## LED-Strip

|

|

153

|

209

|

|

|

154

|

210

|

Depending on where the printer is located, it can be very hard to see any details of the printing process.

|

|

155

|

211

|

That's why one of the first modifications I did, long before using OctoPrint, consisted of sticking two pieces of white 12V LED-Strips inside to the backside of the front acrylic plate.

|

|

|

@@ -157,11 +213,10 @@ Initially, I wired it to the main 12V connection to the printer, so the light wa

|

|

157

|

213

|

Nowadays I'm using the second relay connected to the Raspberry Pi Zero to switch the light on and off independently from the printer itself.

|

|

158

|

214

|

This is very convenient to turn the lights off when printing overnight.

|

|

159

|

215

|

|

|

160

|

|

-### TODO

|

|

|

216

|

+## Slicing Profiles

|

|

|

217

|

+

|

|

|

218

|

+

|

|

|

219

|

+

|

|

|

220

|

+## Print Results Pictures

|

|

161

|

221

|

|

|

162

|

|

-* Firmware

|

|

163

|

|

-* Feet

|

|

164

|

|

-* Spool mount

|

|

165

|

|

-* Slicing Profiles

|

|

166

|

|

-* Print Results Pictures

|

|

167

|

222

|

|