Browse Source

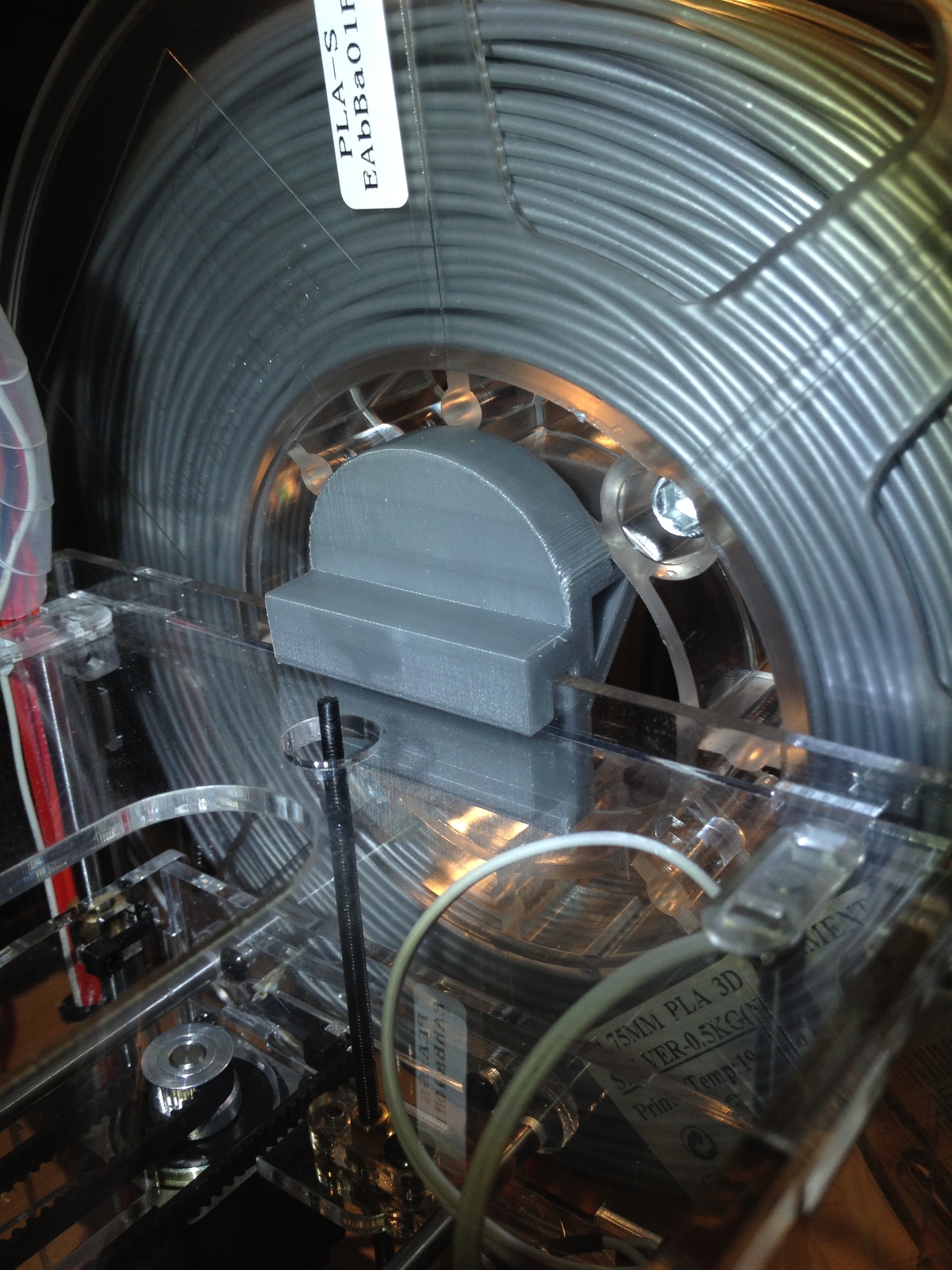

Added some 3D printer photos and text. Added OctoTray page.

37 changed files with 187 additions and 101 deletions

+ 80

- 25

input/projects/3d-printing/fabrikator-mini.md

View File

|

|

||

| 22 |

|

22 |

|

| 23 |

|

23 |

|

| 24 |

|

24 |

|

| 25 |

|

|

|

|

25 |

|

|

|

26 |

|

|

|

27 |

|

|

|

28 |

|

|

|

29 |

|

|

|

30 |

|

|

|

31 |

|

|

|

32 |

|

|

|

33 |

|

|

|

34 |

|

|

|

35 |

|

|

|

36 |

|

|

|

37 |

|

|

|

38 |

|

|

|

39 |

|

|

|

40 |

|

|

|

41 |

|

|

|

42 |

|

|

|

43 |

|

|

|

44 |

|

|

|

45 |

|

|

|

46 |

|

|

|

47 |

|

|

|

48 |

|

|

|

49 |

|

|

| 26 |

|

50 |

|

| 27 |

|

51 |

|

| 28 |

|

52 |

|

|

|

||

| 34 |

|

58 |

|

| 35 |

|

59 |

|

| 36 |

|

60 |

|

| 37 |

|

|

|

|

61 |

|

|

| 38 |

|

62 |

|

| 39 |

|

63 |

|

| 40 |

|

64 |

|

| 41 |

|

65 |

|

| 42 |

|

66 |

|

| 43 |

|

|

|

|

67 |

|

|

| 44 |

|

68 |

|

| 45 |

|

69 |

|

| 46 |

|

70 |

|

|

|

||

| 48 |

|

72 |

|

| 49 |

|

73 |

|

| 50 |

|

74 |

|

| 51 |

|

|

|

|

75 |

|

|

|

76 |

|

|

|

77 |

|

|

|

78 |

|

|

|

79 |

|

|

|

80 |

|

|

|

81 |

|

|

|

82 |

|

|

|

83 |

|

|

|

84 |

|

|

|

85 |

|

|

| 52 |

|

86 |

|

| 53 |

|

87 |

|

| 54 |

|

88 |

|

|

|

||

| 62 |

|

96 |

|

| 63 |

|

97 |

|

| 64 |

|

98 |

|

| 65 |

|

|

|

|

99 |

|

|

| 66 |

|

100 |

|

| 67 |

|

101 |

|

| 68 |

|

102 |

|

|

|

||

| 76 |

|

110 |

|

| 77 |

|

111 |

|

| 78 |

|

112 |

|

| 79 |

|

|

|

|

113 |

|

|

|

114 |

|

|

|

115 |

|

|

|

116 |

|

|

|

117 |

|

|

|

118 |

|

|

|

119 |

|

|

|

120 |

|

|

|

121 |

|

|

|

122 |

|

|

| 80 |

|

123 |

|

| 81 |

|

|

|

|

124 |

|

|

| 82 |

|

125 |

|

| 83 |

|

126 |

|

| 84 |

|

127 |

|

|

|

||

| 90 |

|

133 |

|

| 91 |

|

134 |

|

| 92 |

|

135 |

|

| 93 |

|

|

|

|

136 |

|

|

| 94 |

|

137 |

|

| 95 |

|

138 |

|

| 96 |

|

139 |

|

|

|

||

| 101 |

|

144 |

|

| 102 |

|

145 |

|

| 103 |

|

146 |

|

| 104 |

|

|

|

|

147 |

|

|

| 105 |

|

148 |

|

| 106 |

|

149 |

|

| 107 |

|

|

|

|

150 |

|

|

| 108 |

|

151 |

|

| 109 |

|

152 |

|

| 110 |

|

153 |

|

| 111 |

|

|

|

|

154 |

|

|

|

155 |

|

|

|

156 |

|

|

|

157 |

|

|

|

158 |

|

|

|

159 |

|

|

|

160 |

|

|

| 112 |

|

161 |

|

| 113 |

|

|

|

|

162 |

|

|

| 114 |

|

163 |

|

| 115 |

|

164 |

|

| 116 |

|

165 |

|

|

|

||

| 119 |

|

168 |

|

| 120 |

|

169 |

|

| 121 |

|

170 |

|

| 122 |

|

|

|

|

171 |

|

|

| 123 |

|

172 |

|

| 124 |

|

|

|

|

173 |

|

|

|

174 |

|

|

|

175 |

|

|

|

176 |

|

|

| 125 |

|

177 |

|

| 126 |

|

178 |

|

| 127 |

|

179 |

|

| 128 |

|

|

|

|

180 |

|

|

| 129 |

|

181 |

|

| 130 |

|

182 |

|

| 131 |

|

183 |

|

| 132 |

|

184 |

|

| 133 |

|

185 |

|

| 134 |

|

|

|

|

186 |

|

|

| 135 |

|

187 |

|

| 136 |

|

188 |

|

| 137 |

|

189 |

|

| 138 |

|

|

|

|

190 |

|

|

| 139 |

|

191 |

|

| 140 |

|

192 |

|

| 141 |

|

193 |

|

|

|

||

| 147 |

|

199 |

|

| 148 |

|

200 |

|

| 149 |

|

201 |

|

| 150 |

|

|

|

|

202 |

|

|

|

203 |

|

|

|

204 |

|

|

|

205 |

|

|

|

206 |

|

|

| 151 |

|

207 |

|

| 152 |

|

|

|

|

208 |

|

|

| 153 |

|

209 |

|

| 154 |

|

210 |

|

| 155 |

|

211 |

|

|

|

||

| 157 |

|

213 |

|

| 158 |

|

214 |

|

| 159 |

|

215 |

|

| 160 |

|

|

|

|

216 |

|

|

|

217 |

|

|

|

218 |

|

|

|

219 |

|

|

|

220 |

|

|

| 161 |

|

221 |

|

| 162 |

|

|

|

| 163 |

|

|

|

| 164 |

|

|

|

| 165 |

|

|

|

| 166 |

|

|

|

| 167 |

|

222 |

|

+ 63

- 64

input/projects/3d-printing/ikea-lack.md

View File

|

|

||

| 8 |

|

8 |

|

| 9 |

|

9 |

|

| 10 |

|

10 |

|

| 11 |

|

|

|

|

11 |

|

|

|

12 |

|

|

|

13 |

|

|

| 12 |

|

14 |

|

| 13 |

|

|

|

|

15 |

|

|

|

16 |

|

|

|

17 |

|

|

|

18 |

|

|

|

19 |

|

|

|

20 |

|

|

|

21 |

|

|

|

22 |

|

|

|

23 |

|

|

|

24 |

|

|

|

25 |

|

|

|

26 |

|

|

|

27 |

|

|

|

28 |

|

|

|

29 |

|

|

|

30 |

|

|

|

31 |

|

|

|

32 |

|

|

|

33 |

|

|

|

34 |

|

|

|

35 |

|

|

|

36 |

|

|

|

37 |

|

|

|

38 |

|

|

|

39 |

|

|

|

40 |

|

|

| 14 |

|

41 |

|

| 15 |

|

42 |

|

| 16 |

|

43 |

|

|

|

||

| 22 |

|

49 |

|

| 23 |

|

50 |

|

| 24 |

|

51 |

|

| 25 |

|

|

|

| 26 |

|

|

|

| 27 |

|

|

|

| 28 |

|

|

|

| 29 |

|

|

|

| 30 |

|

|

|

| 31 |

|

|

|

| 32 |

|

|

|

| 33 |

|

|

|

| 34 |

|

|

|

| 35 |

|

|

|

|

52 |

|

|

|

53 |

|

|

|

54 |

|

|

|

55 |

|

|

|

56 |

|

|

|

57 |

|

|

|

58 |

|

|

| 36 |

|

59 |

|

| 37 |

|

60 |

|

| 38 |

|

61 |

|

|

|

||

| 41 |

|

64 |

|

| 42 |

|

65 |

|

| 43 |

|

66 |

|

| 44 |

|

|

|

| 45 |

|

|

|

| 46 |

|

|

|

| 47 |

|

|

|

| 48 |

|

|

|

| 49 |

|

|

|

| 50 |

|

|

|

| 51 |

|

|

|

| 52 |

|

|

|

| 53 |

|

|

|

| 54 |

|

|

|

| 55 |

|

|

|

| 56 |

|

|

|

| 57 |

|

|

|

| 58 |

|

|

|

| 59 |

|

|

|

| 60 |

|

|

|

| 61 |

|

|

|

| 62 |

|

|

|

| 63 |

|

|

|

|

67 |

|

|

|

68 |

|

|

|

69 |

|

|

|

70 |

|

|

|

71 |

|

|

|

72 |

|

|

|

73 |

|

|

|

74 |

|

|

|

75 |

|

|

|

76 |

|

|

| 64 |

|

77 |

|

| 65 |

|

78 |

|

| 66 |

|

79 |

|

| 67 |

|

80 |

|

| 68 |

|

81 |

|

| 69 |

|

82 |

|

| 70 |

|

|

|

| 71 |

|

|

|

| 72 |

|

|

|

| 73 |

|

|

|

| 74 |

|

|

|

| 75 |

|

|

|

| 76 |

|

|

|

| 77 |

|

|

|

| 78 |

|

|

|

| 79 |

|

|

|

| 80 |

|

|

|

| 81 |

|

|

|

| 82 |

|

|

|

| 83 |

|

|

|

|

83 |

|

|

|

84 |

|

|

|

85 |

|

|

|

86 |

|

|

|

87 |

|

|

|

88 |

|

|

|

89 |

|

|

|

90 |

|

|

| 84 |

|

91 |

|

| 85 |

|

92 |

|

| 86 |

|

93 |

|

| 87 |

|

94 |

|

| 88 |

|

95 |

|

| 89 |

|

|

|

| 90 |

|

|

|

| 91 |

|

|

|

| 92 |

|

|

|

| 93 |

|

|

|

| 94 |

|

|

|

| 95 |

|

|

|

| 96 |

|

|

|

| 97 |

|

|

|

| 98 |

|

|

|

| 99 |

|

|

|

| 100 |

|

|

|

| 101 |

|

|

|

| 102 |

|

|

|

| 103 |

|

|

|

| 104 |

|

|

|

| 105 |

|

|

|

|

96 |

|

|

|

97 |

|

|

|

98 |

|

|

|

99 |

|

|

|

100 |

|

|

|

101 |

|

|

|

102 |

|

|

|

103 |

|

|

|

104 |

|

+ 19

- 11

input/projects/3d-printing/octoprint.md

View File

|

|

||

| 27 |

|

27 |

|

| 28 |

|

28 |

|

| 29 |

|

29 |

|

| 30 |

|

|

|

|

30 |

|

|

|

31 |

|

|

| 31 |

|

32 |

|

| 32 |

|

33 |

|

| 33 |

|

34 |

|

| 34 |

|

35 |

|

| 35 |

|

|

|

|

36 |

|

|

| 36 |

|

37 |

|

| 37 |

|

38 |

|

| 38 |

|

|

|

|

39 |

|

|

| 39 |

|

40 |

|

| 40 |

|

41 |

|

| 41 |

|

42 |

|

|

|

||

| 44 |

|

45 |

|

| 45 |

|

46 |

|

| 46 |

|

47 |

|

| 47 |

|

|

|

| 48 |

|

|

|

| 49 |

|

|

|

|

48 |

|

|

|

49 |

|

|

|

50 |

|

|

| 50 |

|

51 |

|

| 51 |

|

52 |

|

| 52 |

|

53 |

|

| 53 |

|

|

|

| 54 |

|

|

|

| 55 |

|

|

|

|

54 |

|

|

|

55 |

|

|

|

56 |

|

|

| 56 |

|

57 |

|

| 57 |

|

58 |

|

| 58 |

|

59 |

|

|

|

||

| 64 |

|

65 |

|

| 65 |

|

66 |

|

| 66 |

|

67 |

|

|

68 |

|

|

| 67 |

|

69 |

|

| 68 |

|

70 |

|

| 69 |

|

71 |

|

|

|

||

| 87 |

|

89 |

|

| 88 |

|

90 |

|

| 89 |

|

91 |

|

| 90 |

|

|

|

|

92 |

|

|

| 91 |

|

93 |

|

| 92 |

|

94 |

|

| 93 |

|

95 |

|

|

|

||

| 95 |

|

97 |

|

| 96 |

|

98 |

|

| 97 |

|

99 |

|

| 98 |

|

|

|

|

100 |

|

|

|

101 |

|

|

|

102 |

|

|

|

103 |

|

|

|

104 |

|

|

|

105 |

|

|

|

106 |

|

|

| 99 |

|

107 |

|

| 100 |

|

108 |

|

| 101 |

|

109 |

|

+ 24

- 0

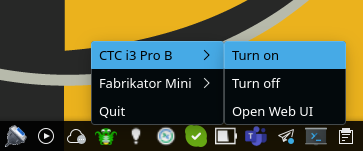

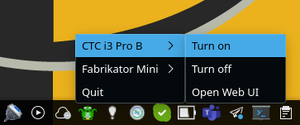

input/projects/3d-printing/octotray.md

View File

|

|

||

|

1 |

|

|

|

2 |

|

|

|

3 |

|

|

|

4 |

|

|

|

5 |

|

|

|

6 |

|

|

|

7 |

|

|

|

8 |

|

|

|

9 |

|

|

|

10 |

|

|

|

11 |

|

|

|

12 |

|

|

|

13 |

|

|

|

14 |

|

|

|

15 |

|

|

|

16 |

|

|

|

17 |

|

|

|

18 |

|

|

|

19 |

|

|

|

20 |

|

|

|

21 |

|

|

|

22 |

|

|

|

23 |

|

|

|

24 |

|

+ 1

- 1

macros.py

View File

|

|

||

| 232 |

|

232 |

|

| 233 |

|

233 |

|

| 234 |

|

234 |

|

| 235 |

|

|

|

|

235 |

|

|

| 236 |

|

236 |

|

| 237 |

|

237 |

|

| 238 |

|

238 |

|

BIN

static/img/fabmin_disp_1.jpg

View File

BIN

static/img/fabmin_disp_1_small.jpg

View File

BIN

static/img/fabmin_disp_2.jpg

View File

BIN

static/img/fabmin_disp_2_small.jpg

View File

BIN

static/img/fabmin_disp_3.jpg

View File

BIN

static/img/fabmin_disp_3_small.jpg

View File

BIN

static/img/fabmin_spool_1.jpg

View File

BIN

static/img/fabmin_spool_1_small.jpg

View File

BIN

static/img/fabmin_spool_2.png

View File

BIN

static/img/fabmin_spool_2_small.png

View File

BIN

static/img/fabmin_spool_3.jpg

View File

BIN

static/img/fabmin_spool_3_small.jpg

View File

BIN

static/img/fabmin_spool_4.jpg

View File

BIN

static/img/fabmin_spool_4_small.jpg

View File

BIN

static/img/fabmin_webcam_1.jpg

View File

BIN

static/img/fabmin_webcam_1_small.jpg

View File

BIN

static/img/fabmin_yfan_1.jpg

View File

BIN

static/img/fabmin_yfan_1_small.jpg

View File

BIN

static/img/fabmin_yfan_2.jpg

View File

BIN

static/img/fabmin_yfan_2_small.jpg

View File

BIN

static/img/fabmin_yfan_3.jpg

View File

BIN

static/img/fabmin_yfan_3_small.jpg

View File

BIN

static/img/fabmin_yfan_4.jpg

View File

BIN

static/img/fabmin_yfan_4_small.jpg

View File

BIN

static/img/fabmin_yfan_5.jpg

View File

BIN

static/img/fabmin_yfan_5_small.jpg

View File

BIN

static/img/fabmin_zfan_1.jpg

View File

BIN

static/img/fabmin_zfan_1_small.jpg

View File

BIN

static/img/lack-simple-bracket.png

View File

BIN

static/img/lack-simple-bracket_small.png

View File

BIN

static/img/octotray_1.png

View File

BIN

static/img/octotray_1_small.png

View File

Loading…